This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

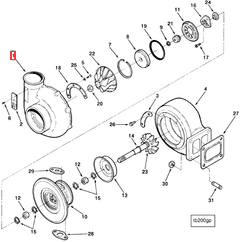

The Cummins 3525002 Compressor Housing is a vital component in heavy-duty truck engines, integral to the turbocharger system. It significantly contributes to engine performance and efficiency. Understanding its function and importance is essential for maintaining and operating heavy-duty trucks effectively.

Basic Concepts of Compressor Housing

A compressor housing, such as the 3525002, is a crucial part of the turbocharger system. It encases the compressor wheel, which compresses the air entering the engine. This compressed air mixes with fuel to create a more powerful combustion, enhancing engine performance. The housing ensures the compressor wheel operates efficiently and is protected from external contaminants 1.

Role in Truck Operation

This Cummins part plays a significant role in truck operation by providing a secure and efficient environment for the compressor wheel. It interacts with other turbocharger components, such as the turbine housing and the center housing, to ensure smooth operation. The housing helps maintain the pressure and temperature of the air entering the engine, which is vital for optimal engine performance 2.

Key Features

The 3525002 is constructed from durable materials that can withstand the high pressures and temperatures within the turbocharger system. Its design includes precise engineering to ensure efficient airflow and minimal turbulence. Unique attributes such as enhanced sealing mechanisms and robust construction contribute to its performance and durability 3.

Benefits of Using the 3525002

Using this part can lead to improved engine efficiency, as it ensures that the compressor wheel operates under optimal conditions. The housing’s durable construction enhances the longevity of the turbocharger system, while its efficient design can contribute to potential increases in power output. These benefits make it a valuable component for heavy-duty truck engines.

Troubleshooting Common Issues

Common issues with compressor housings may include leaks, cracks, or performance declines. Identifying these issues early can prevent more significant problems down the line. Regular inspections and maintenance can help detect signs of wear or damage, allowing for timely repairs or replacements.

Maintenance Tips

To ensure optimal performance and longevity of the 3525002, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any contaminants, and following manufacturer guidelines for replacement. Proper maintenance can help prevent issues and ensure the turbocharger system operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry. With a history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance and efficiency of engines. The company’s reputation for reliability and durability makes its components, like the 3525002, a popular choice for heavy-duty applications.

Compatibility

The 3525002 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a crucial housing for the compressor, which is essential for the engine’s air intake system.

L10 MECHANICAL Engines

For the L10 MECHANICAL engines, the 3525002 is a precise fit, ensuring that the compressor operates efficiently within the engine’s design parameters. This compatibility is critical for maintaining the engine’s performance and longevity, as the housing must withstand the rigors of engine operation while providing a secure environment for the compressor.

Other Compatible Engines

While the primary focus here is on the L10 MECHANICAL engines, it is important to note that the 3525002 may also be compatible with other Cummins engine models. This part’s design and specifications are crafted to ensure it fits a range of engines, making it a versatile component in the Cummins engine lineup.

For users of other Cummins engines, it is advisable to consult the specific engine documentation or contact Cummins technical support to confirm compatibility with the 3525002. This ensures that the part will integrate smoothly with the engine, providing the necessary support and functionality for the compressor.

Understanding the Role in Engine Systems

The 3525002 is an integral component in the functionality of turbocharger systems, particularly within the H2D Turbocharger setup. This housing encases the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chamber. The efficient operation of the compressor housing directly influences the performance and reliability of the turbocharger.

Integration with Turbocharger Components

- Compressor Wheel: The compressor housing is designed to fit snugly around the compressor wheel. This ensures that the air compression process is as efficient as possible, minimizing air leaks and maximizing pressure.

- Turbocharger Kit: When installed as part of a turbocharger kit, the compressor housing works in concert with other components such as the turbine housing, center housing, and wastegate. Each of these parts plays a specific role, but the compressor housing is essential for maintaining the integrity of the compressed air flow.

- Performance Parts: High-performance turbocharger kits often include upgraded compressor housings to handle increased airflow demands. The 3525002 is engineered to provide optimal airflow and pressure, enhancing the overall performance of the engine.

- Intake System: The compressor housing connects to the intake system, where the compressed air is delivered. A well-fitted housing ensures that the intake system receives a consistent and high-pressure air supply, which is vital for engine performance.

- Intercooler: In turbocharged engines, the compressed air is often routed through an intercooler to reduce its temperature before entering the combustion chamber. The compressor housing must be compatible with the intercooler setup to ensure efficient cooling and further optimization of air density.

Impact on Engine Performance

The efficiency of the 3525002 directly affects the engine’s performance metrics, including horsepower, torque, and fuel efficiency. A well-designed and properly fitted compressor housing allows for:

- Increased Airflow: Enhanced airflow leads to better combustion, resulting in higher power output.

- Reduced Turbo Lag: Efficient compression reduces the time it takes for the turbocharger to spool up, improving drivability.

- Improved Reliability: A robust compressor housing minimizes the risk of leaks and component failure, ensuring long-term reliability.

Conclusion

The 3525002 Compressor Housing is a key element in the turbocharger system, influencing both the performance and durability of the engine. Its proper integration with other components ensures that the turbocharger operates at peak efficiency, contributing to the overall success of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.