This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3899517 Compression Spring is a specialized component designed for use in commercial truck operations. Its purpose is to provide necessary mechanical support and functionality within the truck’s systems. The significance of this spring lies in its ability to ensure the smooth and efficient operation of various truck components, contributing to overall vehicle performance and reliability.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various mechanical systems to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. These springs are characterized by their coil design, which allows them to compress and expand as needed. Common applications include suspension systems, engine components, and various machinery where consistent force and reliable performance are required 1.

Role of the 3899517 Compression Spring in Truck Operations

The 3899517 Compression Spring plays a specific role in the operation of commercial trucks by providing the necessary force and support within the truck’s mechanical systems. It is often used in applications where consistent pressure and reliable performance are crucial. This spring helps in maintaining the integrity of the truck’s components by ensuring that parts remain in proper alignment and function as intended under various operating conditions.

Key Features of the 3899517 Compression Spring

The design and construction of the 3899517 Compression Spring include several key features that enhance its performance and durability. The spring is typically made from high-quality materials, such as steel alloys, which provide strength and resistance to wear. Its coil diameter, wire diameter, and free length are precisely engineered to meet the specific requirements of its application. These dimensions ensure that the spring can handle the compressive forces it will encounter while maintaining its structural integrity over time 2.

Benefits of Using the 3899517 Compression Spring

The advantages of using the 3899517 Compression Spring include enhanced durability, reliability, and performance in truck operations. The high-quality materials and precise engineering contribute to its longevity and consistent performance. This spring helps in reducing maintenance needs and improving the overall efficiency of the truck’s mechanical systems. Its reliable operation ensures that the truck can perform optimally under various conditions, leading to increased uptime and productivity 3.

Installation and Integration

Proper installation and integration of the 3899517 Compression Spring within the truck’s mechanical systems are important for ensuring its effective performance. Installation guidelines typically include verifying that the spring is correctly aligned and securely fitted within its designated space. Any specific procedures or precautions, such as using the correct tools and following the manufacturer’s recommendations, should be adhered to during installation to prevent damage and ensure optimal functionality.

Troubleshooting and Maintenance

Identifying common issues related to the 3899517 Compression Spring and implementing maintenance practices can help ensure its longevity. Regular inspections for signs of wear, deformation, or damage are recommended. Maintenance practices may include cleaning the spring and its surrounding components to prevent buildup of dirt or debris that could affect performance. If replacement or repair is necessary, following the manufacturer’s guidelines ensures that the spring continues to function as intended.

Performance and Efficiency

The 3899517 Compression Spring contributes to the overall performance and efficiency of the truck by providing consistent force and support within its mechanical systems. Its reliable operation helps in maintaining the alignment and functionality of various components, leading to smoother and more efficient truck operation. Relevant data and case studies may demonstrate the spring’s positive impact on truck performance, highlighting its role in enhancing operational efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in engine and power generation technologies. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the needs of various industries. Cummins’ commitment to quality and performance has earned it a respected position in the market, making its components, like the 3899517 Compression Spring, trusted choices for commercial truck operators.

Compression Spring Part 3899517 Compatibility with Cummins Engines

The Compression Spring part number 3899517, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to provide the necessary compression and support within the engine’s internal mechanisms, ensuring optimal performance and longevity.

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The Compression Spring part 3899517 is compatible with the ISC series engines, which include the ISC CM2150, ISC CM554, ISC CM850, and ISC8.3 CM2250. These engines are known for their robust design and reliability, often used in heavy-duty applications.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series engines, including the ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, and ISL9 CM2250, also utilize the Compression Spring part 3899517. These engines are designed for high performance and efficiency, commonly found in on-highway and vocational applications.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM11 CM876 SN

The ISM series engines, such as the ISM CM570, ISM CM570/870, and ISM11 CM876 SN, are compatible with the Compression Spring part 3899517. These engines are engineered for durability and are often used in a variety of industrial and agricultural applications.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, also incorporate the Compression Spring part 3899517. These engines are known for their versatility and are used in both on-highway and off-highway applications.

QSC and QSL Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM554

- QSL9 CM850 (CM2850)

The QSC and QSL series engines, such as the QSC8.3 CM554, QSC8.3 CM850 (CM2850), QSL8.9 CM2150 L141, QSL9 CM554, and QSL9 CM850 (CM2850), are compatible with the Compression Spring part 3899517. These engines are designed for high power output and are often used in demanding applications.

QSM11 Series Engine

- QSM11 CM570

The QSM11 CM570 engine also utilizes the Compression Spring part 3899517. This engine is known for its efficiency and reliability, making it suitable for a wide range of applications.

By ensuring the use of the correct Compression Spring part 3899517, these Cummins engines maintain their performance and reliability, providing the necessary support and compression within their internal mechanisms.

Role of Part 3899517 Compression Spring in Engine Systems

The part 3899517 Compression Spring is integral to the efficient operation of various engine components. It is specifically designed to provide the necessary force and stability in the following areas:

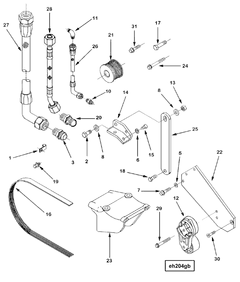

Flywheel Housing and Flywheel Top Level Assembly Housing

In the flywheel housing and the flywheel top level assembly housing, the 3899517 Compression Spring ensures that the flywheel is held securely in place. This is essential for maintaining the proper alignment and balance of the flywheel, which in turn ensures smooth engine operation and consistent power delivery.

Housing and Flywheel

Within the housing that encases the flywheel, the compression spring plays a role in absorbing shocks and vibrations. This helps in prolonging the lifespan of the flywheel and the housing itself by reducing wear and tear.

Idler Gear

The idler gear, which is often used to maintain belt tension in various engine systems, benefits from the consistent force provided by the 3899517 Compression Spring. This ensures that the belt remains taut, which is vital for the efficient transfer of power between different engine components.

Kit and Repto Upfit

In kits and repto upfits that involve engine modifications or upgrades, the compression spring is often included to maintain the integrity and performance of newly installed components. It helps in ensuring that all parts within the kit function harmoniously.

Mounting and Alternator

When it comes to the mounting of the alternator, the 3899517 Compression Spring assists in securing the alternator in its designated position. This is important for the stable operation of the alternator, which is responsible for charging the battery and powering the electrical systems of the vehicle.

Overall, the 3899517 Compression Spring is a versatile component that enhances the functionality and reliability of various engine systems by providing consistent force, absorbing vibrations, and ensuring proper alignment of critical parts.

Conclusion

The Cummins 3899517 Compression Spring is a vital component in the operation of commercial trucks and Cummins engines. Its design and construction ensure durability, reliability, and consistent performance. Proper installation, regular maintenance, and understanding its role within engine systems contribute to the overall efficiency and longevity of the vehicle. By utilizing this part, truck operators and engine manufacturers can achieve optimal performance and reliability in their operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.