This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3053101 Compression Spring is a specialized component designed for use in commercial truck operations. This part plays a role in various mechanical systems within trucks, contributing to their overall functionality and performance. Understanding its purpose and operation is key to maintaining and optimizing truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to exert a force when returning to their original shape. These springs are characterized by their coil design, which allows them to compress and expand efficiently. In mechanical systems, compression springs are utilized for tasks such as absorbing shock, maintaining pressure, and facilitating movement 1.

Purpose of the 3053101 Compression Spring in Truck Operations

The 3053101 Compression Spring is integral to the operation of commercial trucks. It is designed to function within specific mechanical systems, where it helps in absorbing shocks, maintaining consistent pressure, and ensuring smooth operation of components. Its role is particularly significant in systems where precise control of force and movement is required 2.

Key Features

The 3053101 Compression Spring is distinguished by several key features. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design specifications of this spring, including its coil diameter and wire gauge, are tailored to meet the demanding requirements of commercial truck applications. Additionally, it may possess unique attributes that enhance its performance under various operating conditions 3.

Benefits

The use of the 3053101 Compression Spring in truck operations offers several benefits. It contributes to improved performance by ensuring consistent and reliable operation of mechanical systems. Its durable construction enhances the longevity of the spring, reducing the need for frequent replacements. Furthermore, the reliability of this component is crucial for maintaining the overall efficiency and safety of truck operations 4.

Installation and Usage

Proper installation and usage of the 3053101 Compression Spring are vital for its effective operation. Installation guidelines should be followed to ensure the spring is correctly positioned and secured within the mechanical system. Specific instructions may include torque settings for fasteners and alignment procedures to maintain the spring’s integrity and functionality.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for the longevity and optimal performance of the 3053101 Compression Spring. Common issues may include signs of wear, fatigue, or misalignment. Maintenance tips can involve periodic inspections for damage, ensuring proper lubrication, and addressing any signs of deterioration promptly to prevent further complications.

Common Failure Modes

Compression springs, including the 3053101, can experience various failure modes over time. These may include fatigue due to repeated compression and expansion cycles, corrosion from exposure to harsh environments, and physical damage from impacts or improper installation. Recognizing these failure modes is important for timely maintenance and replacement.

Replacement and Upgrades

When the 3053101 Compression Spring shows signs of wear or failure, replacement is necessary to maintain the performance of the truck’s mechanical systems. Replacement procedures should follow manufacturer guidelines to ensure proper fit and function. Additionally, upgrades or alternative parts may be available, offering improved performance or compatibility with newer systems.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient components. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of commercial truck operations.

Compression Spring 3053101 in Cummins Engines

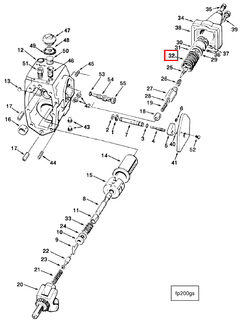

The Compression Spring part number 3053101, manufactured by Cummins, is a critical component in various Cummins engine models. This spring is designed to withstand high pressures and repetitive compression cycles, ensuring the longevity and efficiency of the engine’s operation.

L10 Mechanical Engines

In the L10 Mechanical engines, the Compression Spring 3053101 plays a pivotal role in maintaining the integrity of the engine’s internal mechanisms. It is typically used in the valve train system, where it helps to keep the valves closed under high-pressure conditions, ensuring smooth and reliable engine performance. The spring’s design allows it to absorb and release energy efficiently, contributing to the engine’s overall durability and efficiency.

Grouping of Engines

The Compression Spring 3053101 is compatible with a range of Cummins engines, including but not limited to, the L10 Mechanical series. This part is engineered to meet the stringent requirements of Cummins engines, ensuring that it fits seamlessly and performs optimally within the engine’s architecture. Its application extends to various engine configurations, making it a versatile component in the Cummins engine lineup.

Role of Part 3053101 Compression Spring in Engine Systems

The Part 3053101 Compression Spring is integral to the functionality of several engine components, ensuring optimal performance and efficiency.

Fuel System Integration

In the fuel system, the Compression Spring works in conjunction with the fuel pump to maintain consistent fuel pressure. This is essential for the precise delivery of fuel to the engine, which directly impacts combustion efficiency and overall engine performance. The spring’s role in the fuel pump mechanism helps in regulating the fuel flow, ensuring that the engine receives the correct amount of fuel under varying operational conditions.

Governor Max and Spring Interaction

The Compression Spring is also a key component in the governor max system. Here, it assists in modulating the engine’s speed by applying force to the governor mechanism. This interaction helps in maintaining a stable engine speed, which is vital for the smooth operation of the engine under different loads and conditions.

Calibration and Fuel Code Applications

During engine calibration, the Compression Spring plays a part in fine-tuning the engine’s performance parameters. It interacts with various sensors and actuators to ensure that the engine operates within the desired performance metrics. In fuel code applications, the spring’s properties are utilized to optimize fuel delivery and combustion, contributing to enhanced fuel efficiency and reduced emissions.

Overall Engine Performance

The Compression Spring’s consistent force application across these systems ensures that the engine components operate harmoniously. This results in improved engine reliability, efficiency, and longevity. The spring’s ability to maintain consistent pressure and force is fundamental to the precise functioning of these intricate engine systems.

Conclusion

The Cummins 3053101 Compression Spring is a vital component in commercial truck operations, contributing to the functionality and performance of various mechanical systems. Its role in absorbing shocks, maintaining pressure, and ensuring smooth operation of components is crucial for the overall efficiency and safety of truck operations. Proper installation, maintenance, and timely replacement of this part are essential for maintaining optimal engine performance and longevity.

-

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.