This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

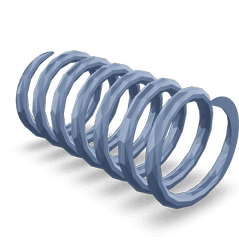

The Cummins 3052124 Compression Coil Spring is a vital component in the suspension systems of commercial trucks. It is designed to absorb and dampen shocks and vibrations, contributing to a smoother ride and enhanced vehicle stability. This spring ensures optimal contact between the truck’s tires and the road surface, which is essential for safety, efficiency, and comfort in commercial trucking operations 1.

Basic Concepts of Compression Coil Springs

Compression coil springs are mechanical components that store energy when compressed. They are widely used in various applications due to their ability to withstand significant loads and return to their original shape after deformation. In mechanical systems, these springs are employed to absorb shock, maintain pressure, and provide a consistent force. Their design allows for efficient energy storage and release, making them indispensable in applications requiring resilience and durability 2.

Role of the 3052124 Compression Coil Spring in Truck Operation

In the context of a commercial truck, the 3052124 Compression Coil Spring supports the vehicle’s weight and absorbs road irregularities. This spring helps maintain tire contact with the road, which is crucial for traction, handling, and overall ride quality. By effectively managing the forces exerted on the truck during operation, it contributes to the longevity of other suspension components and the overall durability of the vehicle 3.

Key Features

The Cummins 3052124 Compression Coil Spring is characterized by its robust material composition, typically made from high-quality steel to ensure durability and resistance to wear. Its design features include a helical coil structure that allows for efficient compression and energy absorption. Specific dimensions and load ratings are tailored to the demands of commercial truck applications, ensuring optimal performance under heavy-duty conditions 4.

Benefits of Using the 3052124 Compression Coil Spring

Utilizing the 3052124 Compression Coil Spring offers several advantages. It contributes to improved ride comfort by effectively dampening road vibrations. Additionally, it enhances the truck’s load-bearing capacity, allowing for safer and more efficient cargo transportation. The spring’s durability ensures long-term performance, reducing the need for frequent replacements and maintenance, which can lead to cost savings and increased operational efficiency 5.

Installation and Integration

Proper installation of the 3052124 Compression Coil Spring within a truck’s suspension system is crucial for optimal performance. It should be integrated according to the manufacturer’s guidelines, ensuring correct alignment and secure attachment to the suspension components. Attention to detail during installation helps prevent issues such as misalignment or excessive wear, which could compromise the spring’s effectiveness and the overall safety of the vehicle 6.

Maintenance and Troubleshooting

Maintaining the 3052124 Compression Coil Spring involves regular inspections to check for signs of wear, corrosion, or damage. Common issues may include loss of spring tension or visible deformation, which can affect the spring’s performance. Addressing these issues promptly through repair or replacement is important to ensure the continued safety and efficiency of the truck’s suspension system 7.

Performance and Longevity

The expected performance and longevity of the 3052124 Compression Coil Spring depend on various operating conditions, including the types of roads traveled, the weight of the cargo, and the overall maintenance of the vehicle. Under normal conditions and with proper care, this spring is designed to provide reliable service for an extended period, contributing to the truck’s operational efficiency and safety 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles 9.

Compatibility with Cummins Engines

The Compression Coil Spring, identified by part number 3052124 and manufactured by Cummins, is a critical component in various engine systems. This part is designed to provide essential support and functionality across a range of Cummins engines, ensuring optimal performance and reliability.

K50 Engines

The Compression Coil Spring is integral to the K50 engine series. It plays a pivotal role in maintaining the structural integrity of the engine’s components, ensuring that the engine operates smoothly and efficiently. This part is particularly important in managing the forces exerted during the engine’s operational cycles, contributing to the longevity and durability of the engine 10.

L10 MECHANICAL Engines

In the L10 MECHANICAL engines, the Compression Coil Spring is utilized to support and stabilize various engine parts. Its design allows it to absorb and distribute the mechanical stresses that occur during engine operation, thereby enhancing the overall performance and reliability of the engine. This spring is crucial in maintaining the precise alignment and operation of the engine’s moving parts 11.

M11 CELECT PLUS Engines

The M11 CELECT PLUS engines also benefit from the Compression Coil Spring. This part is engineered to withstand the high demands of these engines, providing the necessary support to ensure that the engine components remain in optimal condition. The spring’s ability to compress and return to its original shape is vital for the smooth and efficient operation of the engine, contributing to its overall performance and longevity 12.

Role of Part 3052124 Compression Coil Spring in Engine Systems

The 3052124 Compression Coil Spring is an integral component in various engine systems, contributing to the efficient operation of several key elements.

Calibration

In the context of calibration, the Compression Coil Spring assists in maintaining the precise settings required for optimal engine performance. It ensures that components operate within their specified parameters, which is essential for the engine’s overall efficiency and reliability 13.

Fuel Pump

When considering the fuel pump, the Compression Coil Spring plays a supportive role by helping to manage the mechanical stresses and vibrations that the fuel pump experiences during operation. This support is vital for the longevity and consistent performance of the fuel pump, ensuring a steady fuel supply to the engine 14.

Codes and Fuel Codes

In relation to codes and fuel codes, the Compression Coil Spring indirectly influences the diagnostic processes. By ensuring that mechanical components function smoothly, it helps prevent issues that could trigger error codes. This, in turn, aids in maintaining a clean diagnostic record and simplifies troubleshooting efforts 15.

Conclusion

The Cummins 3052124 Compression Coil Spring is a fundamental component that enhances the reliability and performance of both truck suspension systems and engine systems. Its robust design, durability, and efficient energy absorption capabilities make it an indispensable part in ensuring the smooth and efficient operation of commercial trucks. Proper installation, regular maintenance, and prompt troubleshooting are essential to maximize the benefits and longevity of this part.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504622.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Cummins Inc. Corporate Overview. Available at: Cummins Official Website.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504622.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504622.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.