This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

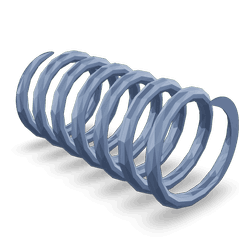

The Cummins 3001161 Compression Spring is a specialized component designed for use in commercial trucks. Its primary purpose is to provide necessary force and support within the truck’s mechanical systems, ensuring efficient and reliable operation. This spring is integral to maintaining the functionality of various truck components, contributing to overall performance and durability 3.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. In mechanical systems, compression springs play a vital role in cushioning impacts, supporting loads, and ensuring the proper functioning of moving parts 1.

Role of the 3001161 Compression Spring in Truck Operation

The Cummins 3001161 Compression Spring is specifically engineered to function within the mechanical systems of commercial trucks. It plays a role in supporting and stabilizing components under load, absorbing vibrations, and ensuring smooth operation of the truck’s systems. By maintaining consistent pressure and support, this spring contributes to the efficient performance of the truck’s mechanical components 4.

Key Features of the 3001161 Compression Spring

The Cummins 3001161 Compression Spring is characterized by its precise design and high-quality materials. Key features include a specific wire diameter, coil diameter, and free length, which are tailored to meet the demands of commercial truck applications. The spring’s load capacity is also a critical factor, ensuring it can handle the stresses and forces encountered in truck operations. These design elements contribute to the spring’s durability and reliability 2.

Benefits of Using the 3001161 Compression Spring

Utilizing the Cummins 3001161 Compression Spring offers several advantages in truck operations. Its durable construction ensures long-term performance, while its reliable design contributes to the overall efficiency of the truck’s mechanical systems. Additionally, the spring’s ability to absorb shocks and vibrations enhances the smoothness and stability of truck operations, leading to improved performance and reduced wear on other components 3.

Installation and Integration

Proper installation of the Cummins 3001161 Compression Spring is vital to ensure it functions correctly within the truck’s mechanical system. Installation guidelines recommend careful handling and precise placement to avoid damage and ensure optimal performance. Specific considerations may include aligning the spring with other components and securing it in place to prevent movement during operation 4.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the Cummins 3001161 Compression Spring continues to perform effectively. Common issues may include wear, deformation, or loss of tension. Diagnostic procedures involve inspecting the spring for signs of damage or malfunction and addressing any issues promptly. Maintenance practices may include cleaning, lubricating, and replacing the spring if necessary to ensure continued optimal performance 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of various industries, including commercial trucking. Cummins’ dedication to quality and innovation ensures that its products, like the 3001161 Compression Spring, deliver reliable performance and durability 3.

Compression Spring Part 3001161 in Cummins Engines

The Compression Spring part 3001161, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to provide essential support and functionality within the engine’s mechanisms.

K38 Engines

In the K38 engine series, the Compression Spring part 3001161 plays a pivotal role in maintaining the integrity and efficiency of the engine’s internal components. Its primary function is to ensure that parts remain tightly compressed, which is crucial for the engine’s operational performance and longevity.

The K38 engines, known for their robust design and reliability, benefit significantly from the precision engineering of the Compression Spring. This part is integral to the engine’s ability to withstand high pressures and stresses, ensuring smooth and consistent performance under various operating conditions 3.

Grouping of Engines

The Compression Spring part 3001161 is not limited to the K38 engines alone. Cummins has designed this part to be compatible with a range of engine models, ensuring that it can be utilized across different engine series. This versatility allows for easier maintenance and repair processes, as the same part can be used in multiple engine types, reducing inventory needs and simplifying logistics.

The integration of the Compression Spring in these engines is a testament to Cummins’ commitment to quality and performance. By using a standardized part across various models, Cummins ensures that the engines maintain their reliability and efficiency, providing users with a dependable power source 3.

Role of Part 3001161 Compression Spring in Engine Systems

In the context of engine systems, the 3001161 Compression Spring is integral to the operation of several key components.

Fuel System Integration

The compression spring is often found within the fuel pump assembly. Here, it assists in maintaining consistent fuel pressure by counteracting the force exerted by the pump’s diaphragm or piston. This ensures a steady fuel supply to the engine, which is essential for optimal combustion and performance 4.

Governor Mechanisms

In governor systems, particularly those involving maximum fuel control, the 3001161 Compression Spring plays a significant role. It helps in modulating the governor’s response to changes in engine load and speed. By providing the necessary tension, the spring ensures that the governor can accurately adjust the fuel delivery, thus maintaining engine stability and efficiency 4.

Interaction with Other Components

The spring’s design allows it to interact effectively with other mechanical parts within the engine system. For instance, in conjunction with the fuel code and governor maximum settings, the compression spring helps in fine-tuning the engine’s performance parameters. This interaction is vital for achieving the desired balance between fuel economy and power output 4.

Overall System Harmony

The 3001161 Compression Spring contributes to the overall harmony of the engine system by ensuring that all moving parts work in sync. Its presence in the fuel pump and governor mechanisms underscores its importance in maintaining the engine’s operational integrity 4.

Conclusion

The Cummins 3001161 Compression Spring is a critical component in the mechanical systems of commercial trucks and Cummins engines. Its precise design, high-quality materials, and reliable performance contribute to the efficient operation and durability of these systems. Proper installation, regular maintenance, and understanding its role within engine systems are essential for maximizing the benefits of this Cummins part.

-

Internal Combustion Engines, Kazimierz Lejda and Pawel Wos, InTech, 2012

↩ -

Automotive Engines Diagnosis Repair and Rebuilding, Tim Giles, Cengage Learning, 2019

↩ ↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015

↩ ↩ ↩ ↩ ↩ -

Gasoline Engine Management Systems and Components, Konrad Reif, Springer Vieweg, 2015

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.