This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 218949 Compression Spring is a specialized component utilized in commercial truck operations. It plays a significant role in ensuring the smooth and efficient functioning of various truck systems. Within the broader context of truck components, this compression spring is integral to maintaining the operational integrity and performance of commercial trucks.

Basic Concepts of Compression Springs

Compression springs are mechanical devices designed to resist compressive forces. When a load is applied, these springs compress, storing potential energy that is released when the load is removed. They are widely used in various mechanical systems for their ability to absorb shock, maintain pressure, and return to their original shape after deformation. Compression springs are typically made from materials like steel, stainless steel, or other alloys, chosen for their strength, durability, and resistance to deformation 1.

Purpose of the 218949 Compression Spring in Truck Operations

The 218949 Compression Spring is specifically designed to play a role in the operation of commercial trucks. It is utilized in systems where shock absorption, pressure maintenance, and reliable return to original form are required. This spring contributes to the functionality and efficiency of the truck’s systems by ensuring consistent performance under varying loads and conditions 2.

Key Features

The Cummins 218949 Compression Spring is characterized by several key features that enhance its performance and durability. Its design is tailored to meet the demanding requirements of commercial truck operations. Constructed from high-quality materials, this spring is built to withstand significant stress and maintain its integrity over time. Unique attributes such as precise coil spacing and surface treatments further contribute to its performance and longevity.

Benefits

Utilizing the 218949 Compression Spring in truck applications offers several advantages. These include improved performance due to its precise design and high-quality materials, enhanced durability under demanding conditions, and increased reliability compared to other types of springs or components. These benefits contribute to the overall efficiency and effectiveness of the truck’s systems 3.

Installation and Integration

Proper installation and integration of the 218949 Compression Spring within a truck’s system are vital for optimal performance and longevity. Guidelines for installation should be followed to ensure that the spring is correctly positioned and secured. This includes verifying that the spring is compatible with the specific truck model and system it is intended for, and that it is installed in a manner that allows for free movement and function within the system.

Troubleshooting and Maintenance

Common issues associated with compression springs can include deformation, loss of tension, or failure to return to the original shape. Troubleshooting these issues involves inspecting the spring for signs of wear or damage, ensuring it is correctly installed, and addressing any environmental factors that may affect its performance. Regular maintenance, such as cleaning and checking for proper function, can help ensure the longevity and efficient operation of the 218949 Compression Spring.

Performance and Efficiency

The 218949 Compression Spring contributes to the overall performance and efficiency of the truck by providing consistent shock absorption, pressure maintenance, and reliable return to original form. Its impact on fuel efficiency, load handling, and other operational aspects is significant, as it helps ensure that the truck’s systems operate smoothly and efficiently under a variety of conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the automotive and commercial truck industry. The company’s dedication to manufacturing high-quality truck components, including the 218949 Compression Spring, underscores its position as a leader in the field.

Compatibility with Cummins Engines

The Compression Spring part number 218949, manufactured by Cummins, is designed to fit a variety of Cummins engines. This spring is integral to the engine’s operation, providing the necessary compression force in various applications. Below is a detailed breakdown of its compatibility across different engine models:

ISM CM570 Series

- ISM CM570: This engine benefits from the 218949 Compression Spring, ensuring optimal performance and longevity.

- ISM CM570/870: The dual-engine configuration of the ISM CM570/870 also utilizes this compression spring, maintaining consistent performance across both engine types.

K Series Engines

- K19: The K19 engine incorporates the 218949 Compression Spring, which is crucial for its operational efficiency.

- K38: Similarly, the K38 engine relies on this compression spring to achieve the necessary compression ratios.

- K50: The K50 engine also uses the 218949 Compression Spring, ensuring reliable performance in demanding conditions.

L10 CELECT Series

- L10 CELECT: This engine model is compatible with the 218949 Compression Spring, enhancing its operational efficiency.

M11 CELECT Series

- M11 CELECT: The M11 CELECT engine utilizes the 218949 Compression Spring, ensuring it meets stringent performance standards.

- M11 CELECT PLUS: The PLUS variant of the M11 CELECT engine also fits this compression spring, maintaining its high-performance capabilities.

N14 CELECT Series

- N14 CELECT: The N14 CELECT engine is designed to work with the 218949 Compression Spring, ensuring reliable and efficient operation.

- N14 MECHANICAL: The mechanical variant of the N14 engine also uses this compression spring, providing consistent performance.

NH/NT 855 Series

- NH/NT 855: This engine model is compatible with the 218949 Compression Spring, ensuring it operates at peak efficiency.

V28

- V28: The V28 engine also utilizes the 218949 Compression Spring, ensuring it meets the necessary performance criteria.

This compression spring is a critical component in these engines, providing the necessary force to maintain compression and ensuring the engine operates smoothly and efficiently.

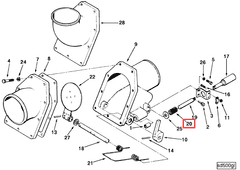

Role of Part 218949 Compression Spring in Engine Systems

The part 218949 Compression Spring is integral to the functionality of several components within engine systems, ensuring smooth operation and reliability.

In the Air Control Valve, the compression spring works to maintain consistent pressure, which is essential for regulating the airflow into the engine. This regulation ensures optimal combustion efficiency and performance.

For the Air Shut Down Device and Air Shut Down Valve, the spring is responsible for the precise actuation required to close off the air supply to the engine when necessary. This action is vital for safety protocols, allowing for a controlled shutdown in emergency situations or during maintenance.

In the Air Shut-Down Device and Air Shutdown Device, the spring’s role is to provide the necessary force for the device to engage quickly and effectively. This rapid response is important for preventing damage to the engine and ensuring that the shutdown process is both swift and complete.

The Device Positive Air Shutdown relies on the compression spring to ensure that once the shutdown is initiated, the air supply is completely and permanently cut off. This feature is particularly important in high-stakes environments where immediate and total cessation of engine operation is required.

Overall, the part 218949 Compression Spring is a key component in these systems, contributing to the precision, safety, and efficiency of engine operations.

Conclusion

The Cummins 218949 Compression Spring is a vital component in commercial truck operations, ensuring the smooth and efficient functioning of various truck systems. Its precise design, high-quality materials, and compatibility with a wide range of Cummins engines make it an essential part for maintaining operational integrity and performance. Proper installation, regular maintenance, and understanding its role in engine systems are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.