179826

Compression Spring

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 179826 Compression Spring is a specialized component designed for use in commercial trucks. It is integral to the vehicle’s operation, contributing to the efficiency and reliability of the truck’s mechanical systems. Understanding its role and functionality is key to maintaining the overall performance of commercial vehicles.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various mechanical systems to absorb shock, maintain force between contacting surfaces, and return to their original shape when the force is removed. These springs are fundamental in applications requiring consistent force and reliable performance under varying loads 1.

Role of the 179826 Compression Spring in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks. It is designed to function within the truck’s mechanical systems, providing necessary force and stability. This spring is typically involved in systems where consistent pressure and reliable performance are required, such as in the suspension or engine components, contributing to the truck’s overall operational efficiency.

Key Features of the 179826 Compression Spring

The design and material characteristics of this part are tailored for heavy-duty applications. It is constructed from high-quality materials that offer durability and resistance to wear and tear. The spring’s design ensures it can withstand the rigors of commercial truck use, providing reliable performance over extended periods 2.

Benefits of Using the 179826 Compression Spring

This part offers several advantages in commercial truck applications. Its robust design contributes to improved performance and reliability of the truck’s mechanical systems. Additionally, the spring’s durability ensures longevity, reducing the need for frequent replacements and contributing to the overall efficiency of the vehicle.

Installation and Integration

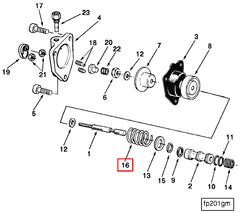

Proper installation and integration of this part are vital for ensuring optimal performance and safety. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the truck’s mechanical systems. Careful attention to detail during installation helps maintain the spring’s effectiveness and the truck’s overall performance.

Troubleshooting Common Issues

Common problems with compression springs can include wear, deformation, or failure to return to the original shape. Regular inspections can help identify these issues early. Solutions may involve replacing the spring or addressing underlying mechanical issues that contribute to spring wear. Proper maintenance and timely replacements are key to maintaining the spring’s functionality.

Maintenance Tips

Regular maintenance of this part is important for ensuring its continued reliable operation. This includes periodic inspections for signs of wear or damage, cleaning to remove dirt and debris, and ensuring it remains properly lubricated if required. Adhering to a maintenance schedule helps prevent potential failures and extends the spring’s service life.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins is committed to providing reliable and efficient solutions for a wide range of industries, including commercial trucking. Their product range reflects a dedication to advancing technology and meeting the needs of their customers.

Compression Spring Part 179826 Compatibility with Cummins Engines

The Compression Spring part number 179826, manufactured by Cummins, is designed to fit a variety of Cummins engines. This spring is crucial for maintaining the performance and reliability of these engines by ensuring proper compression and operational efficiency.

K-Series Engines

The Compression Spring part 179826 is compatible with the following K-Series engines:

- K19

- K38

- K50

These engines are known for their robust design and are commonly used in heavy-duty applications. The spring ensures that the engine components operate within the specified tolerances, enhancing the longevity and efficiency of the engine.

L-Series Engines

For the L-Series engines, the part 179826 is specifically designed to fit the:

- L10 MECHANICAL

This engine is often utilized in various industrial and commercial applications due to its reliability and performance. The compression spring plays a vital role in maintaining the mechanical integrity of the engine.

N-Series Engines

The Compression Spring part 179826 is also compatible with the following N-Series engines:

- N14 MECHANICAL

This engine is widely used in heavy-duty trucks and industrial machinery. The spring ensures that the engine’s components are held together under high-stress conditions, contributing to the overall durability and efficiency of the engine.

NH/NT Series Engines

The part 179826 is designed to fit the:

- NH/NT 855

This engine is known for its high power output and reliability, making it suitable for demanding applications. The compression spring is essential for maintaining the engine’s performance and ensuring that all components function correctly.

V-Series Engines

Lastly, the Compression Spring part 179826 is compatible with the:

- V28

This engine is often used in various heavy-duty applications, and the spring ensures that the engine operates smoothly and efficiently under high-stress conditions.

Role of Part 179826 Compression Spring in Engine Systems

Part 179826 Compression Spring is integral to the efficient operation of several engine components, particularly those involved in fuel delivery and calibration systems.

In the context of fuel pump calibrations, the compression spring assists in maintaining consistent pressure levels. This is essential for the accurate delivery of fuel to the engine, ensuring optimal performance and efficiency. The spring’s role in calibration processes helps in fine-tuning the fuel pump’s output to match the engine’s requirements under varying conditions.

When considering fuel pump codes such as CPL 160, CPL 183, CPL 204, CPL 218, and CPL183, the compression spring plays a part in the mechanical aspects of these systems. It helps in the precise operation of the pump mechanisms, contributing to the reliability and consistency of fuel delivery.

In scenarios involving fuel code calibration, the spring’s ability to provide consistent force is key. It ensures that the calibration settings are maintained over time, despite the wear and tear that naturally occurs in mechanical systems.

Furthermore, in systems where fuel codes are utilized, the compression spring aids in the smooth operation of components that interpret and execute these codes. This is particularly important in modern engines where electronic control units (ECUs) rely on accurate mechanical feedback for optimal fuel management.

Overall, this part is a fundamental component in ensuring the seamless interaction between mechanical and electronic elements in engine systems, particularly in fuel management and calibration processes.

Conclusion

The Cummins 179826 Compression Spring is a critical component in the operation of commercial trucks and Cummins engines. Its design and functionality contribute significantly to the efficiency, reliability, and longevity of these mechanical systems. Proper installation, regular maintenance, and timely replacements are essential for ensuring the optimal performance of this part in various applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.