This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 143849 Compression Spring, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this spring to meet the demanding requirements of truck operations. Compression springs are integral to mechanical systems, providing necessary force and absorbing shock, which is vital for the smooth and efficient operation of vehicles 1.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various mechanical systems to absorb shock, maintain force between contacting surfaces, and store energy. The principle behind compression springs involves the helical coil design, which allows the spring to compress along its axis. When a force is applied, the spring compresses, storing potential energy that is released when the force is removed, allowing the spring to return to its original shape 2.

Role of the 143849 Compression Spring in Truck Operation

The 143849 Compression Spring plays a specific role in the operation of commercial trucks. It is typically associated with the truck’s suspension system, where it helps absorb shocks and vibrations from the road. By doing so, it contributes to a smoother ride and reduces the impact of road irregularities on the truck’s chassis and cargo. Additionally, this spring may be involved in other systems where compression and energy storage are required, enhancing the overall performance and durability of the truck 3.

Key Features of the 143849 Compression Spring

The 143849 Compression Spring is characterized by several key features that set it apart from other compression springs. Its material composition is designed to withstand the rigors of commercial truck use, offering high durability and resistance to wear. The design specifications of this spring, including its coil diameter, wire diameter, and number of coils, are tailored to meet the specific demands of truck applications. Unique characteristics such as its load-bearing capacity and compression ratio further differentiate it, ensuring optimal performance in its intended applications 4.

Benefits of Using the 143849 Compression Spring

Incorporating the 143849 Compression Spring into truck systems offers several advantages. Its design and material composition contribute to improved performance, ensuring that the spring can effectively absorb shocks and maintain its integrity over time. The durability of this spring reduces the frequency of replacements, leading to lower maintenance costs. Additionally, its reliable performance enhances overall truck efficiency, contributing to a smoother operation and potentially extending the lifespan of associated components 5.

Installation and Integration

Proper installation and integration of the 143849 Compression Spring into truck systems are crucial for ensuring its effectiveness. Guidelines for installation include verifying compatibility with other components and adhering to manufacturer recommendations for placement and securing. Special considerations may include ensuring the spring is correctly aligned and that all contacting surfaces are clean and free from debris to prevent premature wear or failure 6.

Troubleshooting and Maintenance

Common issues related to the 143849 Compression Spring may include reduced performance due to wear or damage. Troubleshooting these issues involves inspecting the spring for signs of deformation, corrosion, or excessive wear. Maintenance tips to ensure optimal performance and longevity include regular inspection of the spring and its associated components, cleaning to remove dirt and debris, and replacing the spring if it shows signs of significant wear or damage. Following these guidelines helps maintain the spring’s effectiveness and contributes to the overall reliability of the truck 7.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and commitment to quality. Their product lineup includes a wide range of components designed for heavy-duty applications, reflecting their focus on durability, performance, and reliability. Cummins’ reputation in the industry is built on their dedication to producing high-quality parts that meet the demanding requirements of commercial truck operations 8.

Compression Spring 143849 Compatibility with Cummins Engines

The Compression Spring part number 143849, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, providing necessary compression and maintaining the integrity of the engine’s components.

N14 CELECT and N14 CELECT PLUS Engines

The Compression Spring 143849 is compatible with both the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their advanced electronic control systems, which enhance performance and efficiency. The spring ensures that the engine’s components remain tightly compressed, contributing to the smooth operation and longevity of these engines 9.

N14 MECHANICAL Engine

Similarly, the N14 MECHANICAL engine also utilizes the Compression Spring 143849. This engine variant relies on mechanical controls rather than electronic systems, making the role of the compression spring even more critical. It helps maintain the necessary compression for optimal engine performance 10.

NH/NT 855 Engines

The NH/NT 855 engines are another series where the Compression Spring 143849 is applicable. These engines are part of Cummins’ lineup of heavy-duty diesel engines, designed for robust performance in demanding applications. The spring’s role in these engines is to ensure that the internal components are held together under high pressure, contributing to the engine’s durability and efficiency 11.

Each of these engines benefits from the precise engineering of the Compression Spring 143849, ensuring that they operate at peak performance and reliability.

Role of Part 143849 Compression Spring in Engine Systems

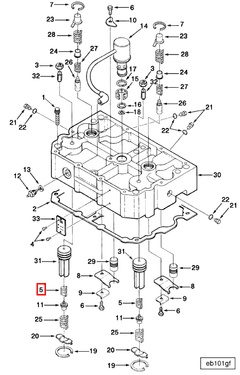

Part 143849 Compression Spring is integral to the functionality of several components within engine systems. In brake systems, this spring aids in maintaining consistent pressure, ensuring reliable braking performance. When integrated into engine brake systems, it contributes to the modulation of braking force, enhancing control and safety.

In the context of C Brake (Top Level) Kits and C Brake (444) Kits, the compression spring works alongside other components to deliver precise braking. It is also a key element in the Cummins Engine Brake and Cummins Engine Brake Kit, where it assists in the efficient operation of the engine brake system.

For Engine Brake Overhaul Kits and Engine Brake Repair Kits, the inclusion of Part 143849 ensures that the braking mechanism can be restored to optimal performance. Additionally, in Governor Weight Carrier systems, this spring helps in balancing the weights, contributing to stable engine operation.

When dealing with Piston Slave Kits, the compression spring plays a role in the smooth operation of the piston, ensuring that the braking system responds accurately to driver inputs. In Fuel Pump KV12 Uncalibrat systems, it assists in maintaining the necessary pressure for fuel delivery, which is vital for engine performance.

Furthermore, in systems with various pump codes such as CPL 101, CPL 158, CPL 187, CPL 22, CPL-101, and CPL-22, the compression spring ensures that the pump operates within the desired parameters, contributing to the overall efficiency of the engine.

In Rocker Housing assemblies, the spring aids in the consistent operation of the rocker arms, which are essential for valve timing and engine performance. Lastly, in Weight Assist Spring systems, it provides the necessary support to maintain the correct weight distribution, ensuring the engine components function harmoniously 12.

Conclusion

The 143849 Compression Spring by Cummins is a critical component in the operation of commercial trucks and various engine systems. Its design and material composition ensure durability, reliable performance, and efficient operation. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this part, contributing to the overall reliability and efficiency of the vehicles it serves.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332798.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.