This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4349744 Compression Spring is a specialized component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. In mechanical systems, compression springs play a role in cushioning impacts, maintaining tension, and ensuring the smooth operation of moving parts 1.

Purpose of the 4349744 Compression Spring

This Cummins part is integral to the operation of a truck, particularly within its mechanical systems. It functions by providing the necessary pressure and support to specific components, ensuring they operate within their designed parameters. This spring helps in maintaining the integrity of the system it is part of, contributing to the truck’s overall performance and durability.

Key Features

This part is characterized by its precise design and high-quality material composition. It is crafted from durable materials to withstand the rigors of commercial truck operation. Unique characteristics such as its coil diameter, wire diameter, and free length are tailored to meet the specific demands of its application, enhancing its performance and longevity.

Benefits

The use of the 4349744 Compression Spring in truck operations offers several benefits. It contributes to improved efficiency by ensuring components operate smoothly and reliably. Its durable construction enhances the longevity of the truck’s mechanical systems, reducing the need for frequent replacements. Additionally, the spring’s reliable performance under various conditions supports the overall reliability of the truck.

Installation and Usage

Proper installation of this part is vital for ensuring optimal performance and longevity. It should be installed according to the manufacturer’s guidelines, taking into account the specific requirements of the truck’s mechanical system. Careful handling and correct positioning are necessary to avoid damage and ensure the spring functions as intended.

Troubleshooting and Maintenance

Common issues with this part may include deformation or loss of tension. Regular inspection and maintenance can help identify and address these issues early, prolonging the spring’s service life. Maintenance practices should include checking for signs of wear, ensuring proper alignment, and replacing the spring if it shows significant signs of damage or failure.

Common Applications

This part finds its application in various truck systems and components. It is commonly used in suspension systems, engine components, and other mechanical parts where compression and tension are required. Its versatility and reliability make it a valuable component in ensuring the smooth operation of these systems.

Performance Under Stress

This part is designed to perform under a range of stress conditions, including load variations and environmental factors. Its material composition and design allow it to withstand the pressures and temperatures encountered in commercial truck operations, ensuring consistent performance and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its wide range of components, including the 4349744 Compression Spring, which is designed to meet the demanding requirements of commercial truck applications.

Compression Spring 4349744 Compatibility with Cummins Engines

This part, manufactured by Cummins, is designed to fit seamlessly within specific engine models. This part is integral to the engine’s operation, ensuring optimal performance and longevity. Below is a detailed description of its compatibility with the listed engines:

QSK95 CM2350 K111 and QSK95 CM2350 K113

This part is engineered to integrate perfectly with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are part of Cummins’ robust lineup, known for their reliability and efficiency. The spring’s design ensures it meets the specific mechanical requirements of these engines, providing the necessary compression and support for various engine components.

The part’s compatibility with these engines is due to its precise dimensions and material properties, which are tailored to withstand the operational stresses and conditions within these engines. This ensures that the spring maintains its integrity and functionality over time, contributing to the overall performance and durability of the engines.

In both the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, this part plays a crucial role in maintaining the engine’s operational efficiency. Its design allows for smooth and reliable performance, making it an essential component for these specific engine models.

Role of Part 4349744 Compression Spring in Engine Systems

In the context of engine systems, this part is an integral component that facilitates the efficient operation of several key elements.

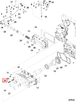

Lubricating Oil Pump

The lubricating oil pump is responsible for circulating oil throughout the engine to reduce friction and wear on moving parts. This part plays a significant role in this system by ensuring consistent pressure is maintained within the pump. It helps in the proper functioning of the pump’s internal mechanisms, allowing for reliable oil delivery to critical engine components.

Lubricating Oil Pump Kit

When considering a lubricating oil pump kit, this part is often included to enhance the kit’s performance. This spring ensures that the pump within the kit operates smoothly, providing consistent oil flow. Its presence in the kit contributes to the overall reliability and efficiency of the oil lubrication system.

Service Kit

In a service kit designed for engine maintenance, this part is a valuable addition. It aids in the restoration and optimization of the lubricating oil pump’s performance. By incorporating this spring into the service kit, mechanics can ensure that the pump will function correctly post-maintenance, thereby prolonging the engine’s lifespan and enhancing its performance.

Conclusion

The Cummins 4349744 Compression Spring is a critical component in the maintenance and optimization of commercial truck performance. Its precise design, durable material composition, and specific application within engine systems highlight its importance in ensuring the smooth operation and longevity of truck mechanical systems. Proper installation, regular maintenance, and understanding its role within various engine components are essential for maximizing the benefits of this part in truck operations.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.