This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

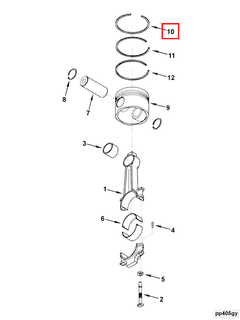

The Cummins 3068813 Compression Piston Ring is a critical component designed for heavy-duty truck engines. It ensures efficient engine performance by maintaining cylinder pressure and enhancing combustion efficiency. This part contributes to the overall reliability and efficiency of the engine.

Basic Concepts of Compression Piston Rings

Compression piston rings are essential components in internal combustion engines. Their primary function is to seal the combustion chamber, ensuring that the air-fuel mixture remains compressed during the combustion process. This sealing action is vital for the engine’s efficiency and performance, preventing gas leakage and maintaining optimal pressure levels within the cylinder 1.

Purpose of the Cummins 3068813 Compression Piston Ring

The Cummins 3068813 Compression Piston Ring is designed to enhance the operation of truck engines. It ensures that the air-fuel mixture is properly sealed within the cylinder during the compression and combustion phases. Additionally, it helps maintain cylinder pressure, which is crucial for efficient engine operation 2.

Key Features

The Cummins 3068813 Compression Piston Ring is characterized by its design and material attributes. It is crafted from high-quality materials that offer durability and resistance to wear. The ring’s design includes features that enhance its sealing capabilities and overall performance within the engine 3.

Benefits

The Cummins 3068813 Compression Piston Ring offers several advantages. These include improved fuel efficiency due to better combustion efficiency, reduced emissions as a result of effective sealing, and enhanced engine longevity owing to its durable construction 4.

Installation and Compatibility

Proper installation of the Cummins 3068813 Compression Piston Ring is essential for ensuring optimal performance. Specific guidelines should be followed during installation to guarantee that the ring is correctly positioned and functions as intended within the engine. This part is compatible with various engines, including the GTA38 G CMEICS G116C, K19, K38, K50, KTA19GC, KTA19GC CM558, KTA38GC CM558, QSK19G, and QSK50 CM2350 K108 5.

Troubleshooting and Maintenance

Common issues associated with compression piston rings can include wear, damage, or improper seating. Diagnosing these problems may involve inspecting the ring for signs of wear or conducting compression tests. Regular maintenance practices, such as proper lubrication and timely replacement, can help prolong the life of the Cummins 3068813 Compression Piston Ring 6.

Performance Enhancements

The Cummins 3068813 Compression Piston Ring contributes to overall engine performance in several ways. It plays a role in achieving higher torque output and horsepower by ensuring efficient combustion. Additionally, it aids in improving fuel economy by maintaining optimal cylinder pressure and reducing energy loss 7.

Material and Durability

The materials used in the Cummins 3068813 Compression Piston Ring are selected for their properties, which contribute to the ring’s durability and resistance to wear. These materials are designed to withstand the high temperatures and pressures encountered within the engine, ensuring long-term performance 8.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performing engine parts. The company’s dedication to excellence is reflected in its wide range of products, including the Cummins 3068813 Compression Piston Ring 9.

Conclusion

The Cummins 3068813 Compression Piston Ring is a vital component in heavy-duty truck engines, ensuring efficient performance and reliability. Its role in maintaining cylinder pressure and enhancing combustion efficiency makes it an essential part of the engine system. Proper installation, regular maintenance, and understanding its compatibility with various engines are key to maximizing its benefits.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩ -

Cummins Inc. QSX15 CM2250 X115, Service Manual (4388739).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.