3007170

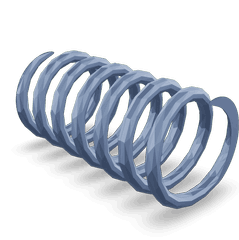

Compression Spring

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3007170 Compression Spring is a specialized component designed for use in commercial trucks. It is integral to the vehicle’s operation, contributing to the efficiency and reliability of the truck’s mechanical systems. Understanding its function and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to absorb shock, maintain force, and return to their original shape once the compressive force is removed. In mechanical systems, compression springs are employed to cushion impacts, maintain pressure, and ensure consistent operation of components 1.

Role of the 3007170 Compression Spring in Truck Operation

The Cummins 3007170 Compression Spring plays a specific role in the operation of commercial trucks. It is designed to absorb and distribute forces within the truck’s mechanical systems, ensuring smooth and reliable performance. This spring is typically found in areas where shock absorption and consistent force application are required, such as in the suspension system or within engine components.

Key Features of the 3007170 Compression Spring

The design and material characteristics of the Cummins 3007170 Compression Spring contribute significantly to its performance and durability. Crafted from high-quality materials, this spring is engineered to withstand the rigors of commercial truck operation. Its precise coil configuration and robust construction ensure it can handle significant loads and maintain its integrity over time.

Benefits of Using the 3007170 Compression Spring

The Cummins 3007170 Compression Spring offers several advantages in truck applications. Its reliable performance enhances the overall efficiency of the truck’s mechanical systems. Additionally, the spring’s durability contributes to the longevity of the truck, reducing the need for frequent replacements and maintenance. This results in cost savings and improved operational reliability.

Installation Considerations

Proper installation of the Cummins 3007170 Compression Spring is vital to ensure optimal performance and safety. It is important to follow manufacturer guidelines and best practices during installation. This includes ensuring the spring is correctly positioned and secured within the truck’s mechanical system. Attention to detail during installation helps prevent issues and ensures the spring functions as intended.

Troubleshooting Common Issues

Common problems associated with compression springs in trucks can include wear, deformation, or failure to maintain consistent force. Troubleshooting these issues involves inspecting the spring for signs of damage, ensuring it is correctly installed, and verifying that it operates within the specified parameters. Addressing these issues promptly can help maintain the truck’s performance and safety.

Maintenance Tips

Regular maintenance of the Cummins 3007170 Compression Spring is important to prolong its service life and ensure consistent performance. This includes periodic inspections for signs of wear or damage, ensuring it remains properly installed, and addressing any issues promptly. Following a maintenance schedule helps prevent unexpected failures and ensures the spring continues to function effectively.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to quality and innovation ensures that its products, including the 3007170 Compression Spring, deliver reliable performance and durability 2.

Role of Part 3007170 Compression Spring in Engine Systems

The 3007170 Compression Spring is integral to the efficient operation of various components within engine systems. Its primary function is to maintain consistent pressure and ensure smooth operation across several critical assemblies.

In the connection lubricating oil transfer system, the compression spring assists in maintaining the necessary pressure for the seamless transfer of lubricating oil. This ensures that the oil reaches all necessary components without interruption, promoting efficient lubrication and reducing wear.

Within the filter and lubricating oil systems, the compression spring plays a role in the lube oil filter head and lubricating oil filter. It helps in keeping the filter elements pressed against the housing, ensuring that contaminants are effectively trapped and the oil remains clean.

The lubricating oil filter / cooler benefits from the compression spring by ensuring that the filter media remains in optimal contact with the cooling surfaces, enhancing both filtration and cooling efficiency.

In the lubricating oil filter head and lubricating oil filter head assembly, the spring ensures that the filter head stays securely in place, preventing leaks and maintaining the integrity of the filtration process.

The lubricating oil filter top level assembly utilizes the compression spring to keep the top-level components aligned and pressurized, which is essential for the consistent performance of the filter.

For the oil connection assembly and oil connector assembly, the spring ensures that connections remain tight and secure, preventing oil leaks and maintaining system pressure.

In the oil filter and oil filter / cooler systems, the compression spring ensures that the filter media is held firmly in place, enhancing the filtration efficiency and prolonging the life of the filter.

The oil transfer connection, oil transfer connection kit, and oil transfer mounting connection all rely on the compression spring to maintain secure and pressure-consistent connections, which is vital for the reliable transfer of lubricating oil throughout the engine system.

Lastly, in the piston cooling plunger system, the compression spring ensures that the plunger operates smoothly and consistently, providing effective cooling to the piston and enhancing engine performance and longevity.

Conclusion

The Cummins 3007170 Compression Spring is a vital component in the operation of commercial trucks and various engine systems. Its role in maintaining consistent pressure, ensuring smooth operation, and contributing to the reliability and efficiency of mechanical systems cannot be overstated. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential to maximize the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.