This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

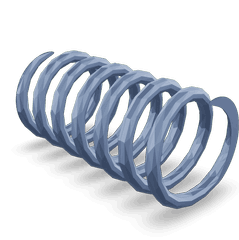

Introduction To Compression Springs

A compression spring is a mechanical component designed to resist compressive forces, storing potential energy when compressed. These springs are essential in various applications, including automotive and heavy-duty truck engines, where they provide necessary force to maintain engine components in their correct positions and ensure smooth operation 1.

How A Compression Spring Works

Compression springs operate on the principle of Hooke’s Law, which states that the force needed to compress a spring is proportional to the distance it is compressed. When a load is applied, the spring deforms and stores energy. Upon removal of the load, the spring returns to its original shape, releasing the stored energy. This characteristic makes compression springs invaluable in engines, where they must withstand repeated cycles of compression and expansion 2.

The Role Of The Cummins 3001153 Compression Spring In Truck Engines

This Cummins part is specifically designed for use in commercial truck engines. Its primary role is to maintain the correct tension and alignment of various engine components, such as valves, pistons, and fuel injectors. By providing consistent force, the spring ensures that these parts operate efficiently and reliably, contributing to the overall performance and longevity of the engine 3.

Importance Of The Cummins 3001153 Compression Spring

In the context of commercial truck engines, the Cummins 3001153 compression spring plays a critical role in several key functions:

- Valve Operation: Ensures that valves open and close at the correct times, facilitating proper air and fuel flow.

- Piston Movement: Maintains the correct tension in piston assemblies, preventing wear and ensuring smooth operation.

- Fuel Injection: Assists in the precise operation of fuel injectors, contributing to efficient combustion and power delivery.

Troubleshooting And Maintenance Of The Cummins 3001153 Compression Spring

Proper maintenance of this part is essential to ensure the longevity and reliability of the engine. Here are some troubleshooting and maintenance tips:

- Regular Inspection: Periodically inspect the spring for signs of wear, such as deformation or corrosion. Any visible damage can indicate the need for replacement.

- Lubrication: Ensure that the spring is adequately lubricated to reduce friction and wear. Use lubricants recommended by Cummins to maintain optimal performance.

- Proper Installation: When replacing the spring, ensure it is installed correctly, with the correct tension and orientation. Incorrect installation can lead to engine malfunctions.

- Monitoring Performance: Keep an eye on engine performance metrics, such as fuel efficiency and power output. Any deviations may indicate issues with the compression spring.

Cummins: A Leader In Engine Technology

Cummins is a renowned manufacturer of engines and related components, known for its commitment to quality and innovation. The company’s extensive experience in the automotive and heavy-duty truck industries has led to the development of high-performance, reliable components like the Cummins 3001153 compression spring. Cummins’ focus on research and development ensures that their products meet the demanding requirements of commercial truck engines.

Role of Part 3001153 Compression Spring in Engine Systems

The 3001153 Compression Spring is integral to the efficient operation of several engine components. It primarily functions to maintain consistent pressure and ensure smooth operation across various systems.

In the calibration process, this spring helps in adjusting and fine-tuning the engine parameters. It ensures that the components operate within specified tolerances, contributing to optimal performance and fuel efficiency.

Within the fuel pump system, the compression spring assists in regulating the fuel delivery. It helps maintain a steady fuel flow, which is essential for consistent engine performance. The spring’s role becomes even more significant when dealing with fuel pump codes and fuel codes, where precise fuel delivery is paramount for engine diagnostics and maintenance.

The governor maximum (gov. max.) settings also benefit from the presence of this spring. It helps in modulating the governor’s response to changes in engine load, ensuring that the engine operates smoothly under varying conditions.

Conclusion

Overall, the 3001153 Compression Spring is a key component in ensuring that these systems work harmoniously, contributing to the engine’s reliability and performance. By understanding its function, importance, and maintenance requirements, engineers, mechanics, truck drivers, and fleet operators can ensure that their engines perform at their best. Cummins’ reputation for quality and innovation further underscores the reliability and effectiveness of their components.

-

Michael Klyde and Kirk VanGelder, Advanced Automotive Electricity and Electronics, Jones Bartlett Learning, 2010.

↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.