This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

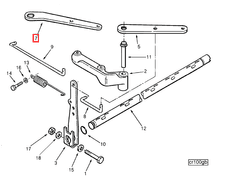

The Cummins 218155 Compression Release Lever is a component designed to enhance the operation of heavy-duty trucks by facilitating efficient engine braking. This lever is integral to the engine’s performance, particularly in scenarios requiring controlled deceleration. Its role in the engine system contributes to both the functionality and safety of heavy-duty vehicles.

Basic Concepts of Compression Release Levers

A Compression Release Lever is a mechanical device used in diesel engines to aid in engine braking. It operates by momentarily releasing the compression within the cylinders, which allows the engine to act as a brake when the vehicle is decelerating. This mechanism reduces the load on the vehicle’s primary braking system, thereby extending its lifespan and improving overall driving safety 1.

Purpose of the 218155 Compression Release Lever

This Cummins part is specifically engineered for Cummins engines. It plays a role in the engine braking system by allowing for the controlled release of compression in the cylinders. This action helps in slowing down the vehicle efficiently, especially during downhill driving or when approaching stops, thus contributing to safer and more controlled deceleration 2.

Key Features

The 218155 is constructed with durability and efficiency in mind. It is made from high-quality materials that ensure longevity and reliable performance. The design incorporates mechanical advantages that enhance its functionality within the engine system. Unique attributes include precise engineering for optimal fit and operation, ensuring it integrates seamlessly with Cummins engines.

Benefits of Using the 218155 Compression Release Lever

Utilizing this part offers several advantages. It contributes to improved engine braking efficiency, which can lead to reduced wear on the vehicle’s braking systems. Additionally, by enhancing the engine’s ability to decelerate effectively, it plays a role in promoting safer driving conditions, particularly in heavy-duty truck operations where controlled deceleration is crucial 3.

Installation and Integration

Proper installation of the 218155 Compression Release Lever is key to ensuring its effective operation within Cummins engines. The process involves several preparatory steps to ensure compatibility and optimal performance. Integration with existing engine components requires careful attention to detail to maintain the engine’s overall efficiency and safety.

Troubleshooting Common Issues

Common issues associated with this part may include malfunctions or signs of wear. Troubleshooting these problems involves a systematic approach to identify the root cause, whether it be mechanical failure, improper installation, or regular wear and tear. Addressing these issues promptly can help maintain the lever’s performance and the engine’s overall efficiency.

Maintenance Tips

Regular maintenance of the 218155 Compression Release Lever is vital for ensuring its optimal performance and longevity. This includes routine inspections to check for any signs of wear or damage, as well as cleaning procedures to remove any debris that may affect its operation. Adhering to recommended maintenance schedules can help prevent issues and ensure the lever continues to function effectively.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history in the industry, Cummins is renowned for its commitment to quality and innovation. The company’s product range includes engines, filtration, emissions solutions, and more, all designed to meet the demanding requirements of the heavy-duty truck industry. Cummins’ reputation for reliability and performance makes it a preferred choice among professionals in the field 4.

Conclusion

The 218155 Compression Release Lever is a vital component in the operation of Cummins engines, particularly in heavy-duty trucks. Its role in facilitating efficient engine braking contributes to the safety and functionality of these vehicles. Understanding its purpose, features, benefits, and maintenance requirements is essential for ensuring optimal performance and longevity of both the lever and the engine system as a whole.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ -

Fischer, Robert, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.