This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 217069 Compression Spring is a specialized component designed for use in commercial trucks. Manufactured by Cummins Inc., a leader in the automotive and commercial truck industry, this part serves a vital role in the mechanical systems of trucks. Compression springs are integral to various mechanical applications due to their ability to store and release energy efficiently. Understanding the function and significance of the Cummins 217069 Compression Spring provides insight into its importance in ensuring the smooth operation of truck components.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that resist compression forces. When a force is applied to compress the spring, it stores potential energy. Upon release of the force, the spring returns to its original shape, releasing the stored energy. This principle is fundamental to the operation of compression springs in various applications, including suspension systems, engine components, and other mechanical assemblies. The ability of compression springs to absorb shock and maintain consistent pressure makes them invaluable in mechanical systems 1.

Purpose of the 217069 Compression Spring in Truck Operations

The Cummins 217069 Compression Spring plays a specific role in the operation of commercial trucks. It is designed to provide consistent pressure and absorb shock within truck components, contributing to the overall functionality and efficiency of the vehicle. By maintaining proper tension and ensuring smooth operation of moving parts, this part helps in reducing wear and tear on truck components, thereby enhancing the reliability and performance of the truck.

Key Features of the 217069 Compression Spring

The Cummins 217069 Compression Spring is characterized by several design and construction features that influence its performance and durability. These include the material composition, coil diameter, wire diameter, and free length. The spring is typically made from high-quality steel, which provides the necessary strength and resilience. The coil diameter and wire diameter are engineered to withstand specific loads and pressures, while the free length determines the spring’s range of motion. These features collectively ensure that the spring can perform reliably under the demanding conditions encountered in commercial truck operations 2.

Benefits of Using the 217069 Compression Spring

Incorporating the Cummins 217069 Compression Spring into truck systems offers several advantages. The spring’s design enhances the reliability of truck components by providing consistent pressure and shock absorption. This results in improved performance and longevity of the truck’s mechanical systems. Additionally, the high-quality materials used in the spring’s construction ensure durability and resistance to wear, contributing to the overall efficiency and reliability of the truck.

Installation and Integration

Proper installation of the Cummins 217069 Compression Spring is crucial for ensuring its effective performance within truck systems. Guidelines for installation include verifying compatibility with other components and following best practices for integration. Careful attention to these steps ensures that the spring functions as intended, providing the necessary pressure and shock absorption to support truck operations.

Troubleshooting and Maintenance

Common issues associated with compression springs include wear, deformation, and loss of tension. Identifying these issues early through regular inspection can prevent more significant problems. Maintenance tips for the Cummins 217069 Compression Spring include periodic checks for signs of wear or damage, ensuring proper lubrication where applicable, and replacing the spring if it shows signs of fatigue or failure. These practices help maintain the spring’s performance and extend its service life 3.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive and commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance truck components, Cummins has established itself as a leader in the field. The company’s dedication to excellence is evident in the design and manufacturing of components like the Cummins 217069 Compression Spring, ensuring that truck operators can rely on their equipment for consistent performance and durability.

Role of Part 217069 Compression Spring in Engine Systems

In the realm of engine systems, the Part 217069 Compression Spring is instrumental in ensuring the efficient operation of various components. This spring is specifically designed to maintain consistent pressure and facilitate smooth functionality across a range of engine subsystems.

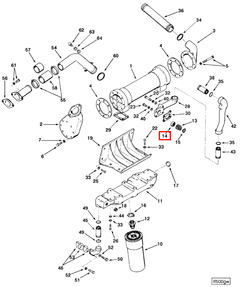

Lubricating Oil System

Within the lubricating oil system, the Part 217069 Compression Spring is employed in the lubricating oil filter assembly. Its primary function here is to ensure that the filter media remains compressed, allowing for optimal filtration of contaminants from the oil. This helps in maintaining the cleanliness of the lubricating oil, which is essential for reducing wear and tear on engine components.

Oil Filter and Cooler Integration

In systems where an oil filter is integrated with a cooler (oil filter / cooler or lubricating oil filter / cooler), the compression spring plays a vital role in maintaining the structural integrity of the assembly. It ensures that the filter media stays in place while the oil is being cooled, thus enhancing the efficiency of both filtration and cooling processes.

Lubricating Filter Head

The lubricating filter head often incorporates the Part 217069 Compression Spring to secure the filter element in position. This is particularly important in high-pressure environments where the filter head is subjected to significant stress. The spring helps in distributing the pressure evenly across the filter media, prolonging its lifespan and ensuring consistent performance.

Lubricating Oil Cooler and Filter

In combined lubricating oil cooler and filter units, the compression spring is used to keep the filter element compressed against the cooler. This setup ensures that the oil is effectively filtered before it enters the cooling process, thereby enhancing the overall efficiency of the lubricating system.

Oil Filter Conversion Kit

When utilizing an oil filter conversion kit, the Part 217069 Compression Spring is often included to adapt the filter to different engine configurations. It ensures that the new filter fits securely and functions as intended, regardless of the specific engine design.

Fuel Code and Lubricating Oil Filter

In systems where a fuel code is integrated with the lubricating oil filter, the compression spring ensures that the filter media remains effective in capturing contaminants. This is particularly important in fuel-sensitive applications where the purity of the lubricating oil directly impacts engine performance.

Lubricating Oil Filter Assembly

The lubricating oil filter assembly often relies on the Part 217069 Compression Spring to maintain the structural integrity of the filter element. This is essential for ensuring that the filter can withstand the pressures and temperatures encountered within the engine system.

Oil Filter Cooler

In oil filter cooler applications, the compression spring ensures that the filter element remains in optimal condition. This is crucial for maintaining the efficiency of both the filtration and cooling processes, contributing to the overall performance of the engine system.

Conclusion

The Cummins 217069 Compression Spring is a critical component in the operation of commercial trucks and Cummins engines. Its design and features ensure consistent pressure, shock absorption, and reliable performance across various engine subsystems. Proper installation, maintenance, and understanding of its role are essential for maximizing the efficiency and longevity of truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.