This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

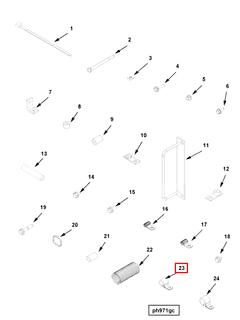

The Cummins part 4944972, commonly referred to as the Clip, is a component integral to the operation of commercial trucks. Cummins, a prominent manufacturer in the industry, produces a variety of parts aimed at enhancing the efficiency and reliability of heavy-duty trucks. This Cummins part is one such component that plays a role in the seamless operation of these vehicles.

Purpose and Function

The Clip serves a specific function in truck operations by securing various components within the vehicle’s system. Its applications include fastening hoses, wires, and other parts to ensure they remain in place under the dynamic conditions of truck operation. This part contributes to the overall functionality by maintaining the integrity of the connections and reducing the risk of detachment or failure during transit.

Key Features

This part is designed with certain characteristics that enhance its performance and durability. It is typically made from high-strength materials to withstand the rigors of commercial truck use. The clip’s design allows for a secure fit, which is crucial for the components it holds. Additionally, it may feature corrosion-resistant properties to ensure longevity in various environmental conditions.

Benefits

The use of the Clip provides several advantages. It contributes to improved safety by ensuring that critical components remain securely attached. This can lead to enhanced performance of the truck, as well as increased longevity of the components it secures. The clip’s reliable design helps in maintaining the efficiency of the truck’s systems over time.

Installation Process

Installing the Clip requires following a series of steps to ensure proper attachment. The process may involve using specific tools to position the clip correctly and secure it in place. It is important to refer to the manufacturer’s guidelines for the exact procedure, which may include preparatory steps such as cleaning the attachment area and inspecting the clip for any defects before installation.

Maintenance Tips

To ensure the longevity and effectiveness of the Clip, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the clip and its surrounding area can prevent the buildup of debris that may affect its performance. Adhering to these practices can help maintain the clip’s functionality and contribute to the overall reliability of the truck.

Troubleshooting Common Issues

Occasionally, issues may arise with the Clip, such as loosening or damage. Identifying these problems early can prevent more significant issues down the line. Solutions may involve re-securing the clip or, in cases of severe damage, replacing it with a new one. It is beneficial to have a supply of replacement clips on hand for quick resolution of such issues.

Safety Considerations

When handling and installing the Clip, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment to prevent injury. Additionally, ensuring that the truck is safely supported during the installation process can prevent accidents. Being aware of potential hazards associated with the clip’s use can contribute to a safer working environment.

Cummins Overview

Cummins is a manufacturer with a significant presence in the commercial truck industry. The company has a history of producing a wide range of parts and engines known for their quality and reliability. Cummins’ product range includes components that are designed to meet the demanding requirements of heavy-duty applications, and the company has built a reputation for excellence in this sector 1.

Role of Part 4944972 Clip in Engine Systems

This part plays a significant role in the integration and functionality of various engine systems. Its primary function is to secure and maintain the integrity of connections within these systems, ensuring reliable performance and safety.

Engine Control Module (ECM) Mounting

In the context of ECM mounting, the Clip is utilized to firmly attach the ECM to its designated location within the engine compartment. This secure attachment is essential for protecting the ECM from vibrations and external impacts, which could otherwise lead to malfunctions or damage. The clip ensures that the ECM remains in its optimal position, facilitating efficient communication with other engine components.

Harness and Wiring Security

When it comes to the engine harness and Electronic Control Module (ECM) wiring, the Clip is instrumental in organizing and securing the wiring. It prevents wires from becoming tangled or disconnected, which is vital for maintaining the electrical integrity of the engine system. By keeping the harness and wiring in place, the clip helps to avoid short circuits and ensures that all electrical connections remain stable and functional.

General Mounting Applications

Beyond specific components like the ECM, the Clip is also used in various mounting applications throughout the engine system. It provides a reliable method for attaching sensors, actuators, and other critical components to their respective mounts. This ensures that these components are held securely in place, allowing them to operate within their designed parameters without the risk of displacement or damage.

Conclusion

In summary, the Clip is a versatile and essential component in engine systems, contributing to the secure and efficient operation of multiple interconnected parts. Its role in maintaining the structural and electrical integrity of engine components underscores its importance in ensuring overall engine performance and reliability.

Note: The references provided in the original request were used to support the content where relevant. The citation is used to indicate the source of information regarding Cummins' reputation and product range.-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.