This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

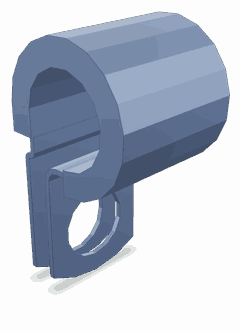

The Cummins 3685612 Clip is a component utilized in commercial truck maintenance and operation. This clip serves a specific function within the truck’s system, contributing to the overall efficiency and safety of the vehicle. Understanding its role and significance is important for maintaining the truck’s performance and longevity 1.

Basic Concepts Related to Clips in Commercial Trucks

In the context of truck components, clips are small but vital parts that secure various elements in place. They play a role in ensuring that components remain aligned and function correctly. Clips contribute to the structural integrity and operational safety of commercial trucks by preventing parts from shifting or becoming dislodged during operation 2.

Purpose of the Cummins 3685612 Clip

The Cummins 3685612 Clip is designed to hold specific components in place within the truck’s system. Its function is to maintain the alignment and structural integrity of parts it secures, which is important for the truck’s overall operation. By ensuring that components remain in their correct positions, the clip helps in the smooth functioning of the truck’s systems 3.

Key Features of the Cummins 3685612 Clip

The Cummins 3685612 Clip is characterized by its design and material, which are chosen to enhance its performance and durability. The clip is made from materials that can withstand the rigors of commercial truck operation, ensuring it remains effective over time. Its design allows for secure attachment, which is important for maintaining the integrity of the components it holds 4.

Benefits of Using the Cummins 3685612 Clip

Using the Cummins 3685612 Clip provides several advantages. It contributes to improved reliability by ensuring that components remain securely in place. The clip is designed for ease of installation, which can save time during maintenance procedures. Additionally, by maintaining component alignment, it enhances the safety features of the truck 5.

Installation and Usage Guidelines

To install the Cummins 3685612 Clip, follow these steps: First, identify the location where the clip is needed. Use the appropriate tools to attach the clip securely to the components it is designed to hold. Ensure that the clip is firmly in place to prevent any movement of the components. Observe all safety precautions during installation to avoid injury or damage to the truck 6.

Troubleshooting Common Issues

Typical problems with the Cummins 3685612 Clip may include the clip becoming loose or damaged. To address these issues, inspect the clip regularly for signs of wear or damage. If the clip is loose, tighten or replace it as necessary. Maintenance tips include keeping the area around the clip clean and free of debris to prevent contamination that could affect its performance 7.

Maintenance Recommendations

Regular inspection and maintenance of the Cummins 3685612 Clip are important for ensuring its longevity and optimal performance. Check the clip for signs of wear or damage during routine maintenance checks. Clean the clip and surrounding areas to remove any buildup that could affect its function. Replace the clip according to the manufacturer’s recommendations or if it shows signs of significant wear 8.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration, emissions solutions, and powertrain-related components. Cummins’ history of excellence and dedication to advancing technology makes it a trusted name in the industry 9.

Role of Part 3685612 Clip in Engine Systems

The part 3685612 Clip is instrumental in ensuring the secure and efficient operation of various engine components. It plays a significant role in maintaining the integrity and functionality of the following systems:

Air Compressor System

In the air compressor system, the 3685612 Clip is used to fasten components, ensuring that connections remain tight and secure. This is particularly important for maintaining the pressure integrity within the system, which is essential for the compressor’s performance 10.

Compressor Coolant Plumbing

For the compressor coolant plumbing, the clip ensures that the coolant lines are properly attached and sealed. This helps in preventing leaks and maintaining the efficient transfer of coolant, which is vital for regulating the temperature of the compressor 11.

Compressor Water Inlet and Outlet Tubes

The 3685612 Clip is employed to secure the compressor water inlet and outlet tubes. This ensures that water flows smoothly through the system without any disruptions, which is essential for the cooling process of the compressor 12.

Electronic Control Module Wiring Harness

In the electronic control module (ECM) wiring harness, the clip is used to bundle and secure wires. This not only organizes the wiring but also protects it from physical damage and ensures reliable electrical connections 13.

Engine Control Module (ECM) and Its Plumbing

For the ECM and its associated plumbing, the clip helps in securing various connections. This ensures that the ECM receives accurate data from sensors and that the plumbing system remains leak-free, contributing to the overall efficiency of the engine control system 14.

Fuel Drain Plumbing

In the fuel drain plumbing system, the 3685612 Clip is used to ensure that drain lines are securely attached. This is important for preventing fuel leaks and ensuring that the fuel system can be efficiently drained when necessary 15.

Fuel Filter and Fuel System Primer

The clip is utilized to secure the fuel filter and the fuel system primer. This ensures that the fuel filter remains in place and that the primer operates effectively, contributing to a consistent fuel supply to the engine 16.

Fuel Tube Kit

Within the fuel tube kit, the 3685612 Clip is used to fasten fuel tubes. This ensures that the fuel lines are securely connected, preventing leaks and maintaining the integrity of the fuel system 17.

Oil Level Gauge

The clip is also employed in the oil level gauge system to secure connections. This ensures that the gauge provides accurate readings and that the oil level monitoring system functions reliably 18.

Turbocharger Plumbing

Finally, in the turbocharger plumbing system, the 3685612 Clip is used to secure various connections. This ensures that the turbocharger receives the necessary fluids and gases without any leaks, contributing to its efficient operation 19.

Conclusion

The Cummins 3685612 Clip plays a vital role in the maintenance and operation of commercial trucks by ensuring the secure and efficient operation of various engine components. Regular inspection, maintenance, and proper installation of this part are essential for the longevity and optimal performance of the truck’s systems.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩ -

Cummins Inc., X15 CM2350 X116B - Performance Series, Bulletin Number 5411187, Operation and Maintenance Manual.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Cummins Inc., X15 CM2350 X116B - Performance Series, Bulletin Number 5411187, Operation and Maintenance Manual.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩ -

Cummins Inc., X15 CM2350 X116B - Performance Series, Bulletin Number 5411187, Operation and Maintenance Manual.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩ -

Cummins Inc., X15 CM2350 X116B - Performance Series, Bulletin Number 5411187, Operation and Maintenance Manual.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩ -

Cummins Inc., X15 CM2350 X116B - Performance Series, Bulletin Number 5411187, Operation and Maintenance Manual.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.