This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

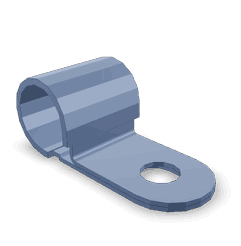

The Cummins 3657725 Clip is a component utilized in the maintenance and operation of commercial trucks. This clip serves a specific function within the truck’s assembly, contributing to the overall efficiency and reliability of the vehicle. Understanding its role and significance is important for maintaining the structural integrity and operational performance of commercial trucks.

Purpose and Function

This Cummins part plays a role in the secure attachment of various components within a truck’s system. It is designed to hold parts in place, ensuring they remain fixed during operation. This function is vital for maintaining the structural integrity of the truck, as it prevents components from shifting or becoming dislodged, which could lead to operational issues or safety hazards 1.

Key Features

The 3657725 Clip is characterized by its robust design and material composition. It is typically made from high-strength materials to withstand the rigors of commercial truck operation. The clip’s design may include features such as a locking mechanism to ensure a secure fit, and it is engineered to resist wear and corrosion, enhancing its durability in various operating conditions 2.

Benefits

Using this Cummins part offers several advantages. It contributes to improved reliability by ensuring components remain securely attached. The clip is designed for ease of installation, which can reduce maintenance time and labor costs. Additionally, its durable construction can lead to long-term cost savings for fleet operators by minimizing the need for frequent replacements.

Installation Process

Installing the 3657725 Clip requires following a specific procedure to ensure a secure fit. The process may involve using standard tools for alignment and tightening. It is important to adhere to best practices, such as verifying the correct orientation of the clip and ensuring it is fully engaged with the components it is designed to hold. This helps in achieving a secure attachment and maintaining the integrity of the truck’s assembly.

Troubleshooting and Maintenance

Common issues with the 3657725 Clip may include loosening or damage over time. Regular inspections can help identify these issues early. Maintenance tips include checking for signs of wear or corrosion and replacing the clip if it shows signs of damage. Proper maintenance can prolong the lifespan of the clip and ensure it continues to perform its function effectively.

Common Applications

The 3657725 Clip is commonly used in various applications within commercial truck systems. It is often found in assemblies where secure component attachment is required. Specific applications may vary, but the clip is typically used in areas where it can contribute to the structural integrity and operational reliability of the truck.

Safety Considerations

When working with the 3657725 Clip, it is important to follow safety procedures. This includes using appropriate personal protective equipment and ensuring the truck is safely supported during maintenance or installation. Being aware of potential hazards, such as sharp edges or moving parts, can help prevent accidents and ensure a safe working environment.

Manufacturer Information

Cummins, the manufacturer of the 3657725 Clip, is known for its commitment to producing reliable automotive components. With a strong reputation in the industry, Cummins emphasizes quality and durability in its products. The company’s history of manufacturing dependable parts contributes to the trust and confidence fleet operators place in Cummins components for their commercial trucks.

Cummins Part 3657725 Clip Compatibility with Cummins Engines

The 3657725 Clip is designed to fit a range of Cummins engines, ensuring compatibility across various models. Here is a detailed overview of its application:

G8.3 Series

- G8.3

- G8.3 CM558

The Clip 3657725 is compatible with the G8.3 series engines, including the G8.3 CM558. This clip is engineered to secure and stabilize components within these engines, ensuring optimal performance and reliability.

GTA38 Series

- GTA38 G CMEICS G116C

For the GTA38 G CMEICS G116C engine, the Clip 3657725 is specifically designed to fit the unique requirements of this model. It provides essential support and alignment for various engine parts, contributing to the engine’s overall efficiency and durability.

GTA8.3 Series

- GTA8.3 CM558

The Clip 3657725 is also suitable for the GTA8.3 CM558 engine. Its design ensures that it can effectively hold and maintain the positioning of critical engine components, enhancing the engine’s operational integrity.

L10 Series

- L10 GAS

In the L10 GAS engine, the Clip 3657725 plays a role in securing and aligning parts, ensuring that the engine operates smoothly and efficiently.

QSK19 Series

- QSK19 CM850 MCRS

The Clip 3657725 is compatible with the QSK19 CM850 MCRS engine, providing necessary support and stability for its components. This ensures that the engine maintains its performance standards under various operating conditions.

QSK60 Series

- QSK60 CM850 MCRS

Similar to the QSK19 series, the Clip 3657725 fits the QSK60 CM850 MCRS engine, offering the same level of support and alignment for its parts.

QSL9 Series

- QSL9 G CM558

The Clip 3657725 is also suitable for the QSL9 G CM558 engine, ensuring that it can effectively secure and align the necessary components for optimal engine performance.

Role of Part 3657725 Clip in Engine Systems

This part is integral to the secure and efficient operation of various engine components. Its application ensures that connections remain intact under operational stresses, contributing to the overall reliability of the engine system.

Crankcase Breather

The Clip is utilized in the crankcase breather system to maintain a secure seal. This is important for managing pressure within the crankcase, ensuring that contaminants are effectively vented while preventing the ingress of external particles.

Drain Location

At the drain location, the Clip plays a role in securing hoses or tubes that are part of the drainage system. This ensures that fluids are directed away from sensitive components, maintaining the cleanliness and integrity of the engine environment.

Electronic Control Module Wiring Harness

In the electronic control module (ECM) wiring harness, the Clip is employed to bundle and secure wires. This not only organizes the wiring but also protects it from physical damage and electrical interference, ensuring consistent signal transmission.

Engine Control Module

Similar to its role in the ECM wiring harness, the Clip is used in the engine control module (ECM) to secure connections and wiring. This helps in maintaining the integrity of the control signals that are vital for engine operation.

Expansion Tank

Within the cooling system’s expansion tank, the Clip secures hoses and connections. This is essential for maintaining the sealed environment necessary for the proper function of the cooling system, preventing leaks and ensuring efficient heat management.

Fuel Control Module

In the fuel control module, the Clip is used to secure fuel lines and electrical connections. This ensures that fuel delivery is consistent and that electrical signals are reliably transmitted, contributing to efficient fuel management.

Ignition System Arrangement

The Clip is integral in the ignition system arrangement, securing spark plug wires and other components. This ensures that ignition timing is precise and that electrical connections are maintained under the high voltages present in the ignition system.

Turbocharger Coolant Plumbing

In turbocharger coolant plumbing, the Clip secures hoses that carry coolant to and from the turbocharger. This is vital for managing the heat generated by the turbocharger, ensuring its longevity and efficient operation.

Wiring Accessories

Across various wiring accessories, the Clip is used to bundle and secure wires. This not only aids in organization but also protects wires from physical damage and reduces the risk of short circuits.

Wiring Harness

Finally, within the main wiring harness, the Clip is extensively used to secure and organize wires. This ensures that the harness remains intact under the dynamic conditions of engine operation, contributing to the reliability of electrical systems.

Conclusion

The Cummins 3657725 Clip plays a significant role in the maintenance and operation of commercial trucks by ensuring the secure attachment of various components. Its robust design, ease of installation, and durable construction contribute to the overall efficiency and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the structural integrity and operational performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.