4898590

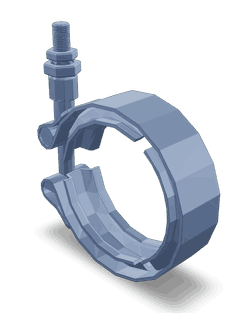

V Band Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The V Band Clamp, specifically Part #4898590 by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established manufacturer in the automotive industry, produces this clamp to meet the demanding requirements of heavy-duty truck operations. This part is integral to ensuring secure and efficient connections in various truck systems.

Basic Concepts of V Band Clamps

V Band Clamps are specialized fasteners used to join pipes and fittings in exhaust, intake, and other fluid transfer systems. They consist of a band that wraps around the pipe and fitting, secured by a single bolt that pulls the band tight, creating a seal. This design allows for easy installation and removal, making them popular in the automotive industry for their efficiency and reliability 4.

Purpose of the 4898590 V Band Clamp in Truck Operations

This Cummins part is utilized in commercial trucks primarily within the exhaust system. It ensures a secure connection between the exhaust components, which is vital for maintaining the system’s integrity and efficiency. Additionally, it plays a role in other areas where a reliable seal is required, contributing to the overall performance and safety of the vehicle 2.

Key Features of the 4898590 V Band Clamp

The 4898590 V Band Clamp is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the high temperatures and pressures typical of truck exhaust systems. The clamp’s design allows for a uniform load distribution around the pipe, enhancing its sealing capability and durability. Its construction from high-grade materials ensures resistance to corrosion and wear, contributing to its longevity in demanding environments 3.

Benefits of Using the 4898590 V Band Clamp

Incorporating this part into truck maintenance and repair offers several advantages. Its design facilitates quick and easy installation, reducing downtime during maintenance procedures. The clamp’s reliability ensures a secure connection, minimizing the risk of leaks and enhancing the system’s efficiency. Furthermore, its ease of installation and removal simplifies maintenance tasks, making it a preferred choice for truck fleet managers and technicians 1.

Installation Process

Installing the 4898590 V Band Clamp requires careful attention to detail to ensure a proper seal. The process involves aligning the clamp around the pipe and fitting, ensuring it is centered and evenly distributed. The single bolt is then tightened to the manufacturer’s specified torque, pulling the band tight and creating a secure seal. It is important to avoid over-tightening, which can damage the components, and to ensure the clamp is installed in a vibration-free area to maintain its effectiveness 4.

Troubleshooting Common Issues

Common issues with V Band Clamps include leaks and improper sealing, often due to incorrect installation or environmental factors. To address these problems, it is important to inspect the clamp for proper alignment and torque. Ensuring the clamp is installed in a location free from excessive vibration can also help prevent issues. If a leak is detected, the clamp should be re-tightened or replaced as necessary to restore the seal 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 4898590 V Band Clamp, regular inspections are recommended. This includes checking for signs of wear, corrosion, or damage to the clamp and the connected components. Cleaning the clamp and its surroundings can prevent the buildup of debris that might affect its sealing capability. Following the manufacturer’s guidelines for torque specifications during installation and re-tightening is also crucial for maintaining the clamp’s effectiveness 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and its focus on reliability and performance make it a trusted name among fleet operators and maintenance professionals.

Cummins V Band Clamp 4898590 Compatibility

The Cummins V Band Clamp part number 4898590 is a versatile component designed to fit a variety of Cummins engines. This clamp is essential for sealing and securing connections in various applications, ensuring that the engine operates efficiently and safely. Below is a detailed overview of the engines with which this V Band Clamp is compatible:

Small Bore Engines

- 4B3.9

- B4.5 CM2350 B129B

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- ISB/ISD4.5 CM2150 B119

- ISB3.9 CM2220 B107

- ISB4.5 CM2350 B104

- ISD4.5 CM2220 D108

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

Medium Bore Engines

- ISB6.7 G CM2180 B118

- ISBE CM800

- ISBE4 CM850

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

Large Bore Engines

- QSB3.3 CM2150

- QSB3.9 CM2880 B138

This V Band Clamp is engineered to provide a reliable seal in high-pressure and high-temperature environments, making it suitable for use in both small and large bore engines. Its robust design ensures a secure fit, preventing leaks and maintaining system integrity.

Role of Part 4898590 V Band Clamp in Engine Systems

Part 4898590 V Band Clamp is integral to the secure and efficient operation of various components within engine systems. Its application ensures robust connections and reliable performance across different parts of the engine.

Air Transfer Connection

In the context of air transfer connections, the V Band Clamp provides a secure seal between the intake manifold and the turbocharger. This ensures that air flows smoothly and efficiently, minimizing leaks that could otherwise degrade engine performance. The clamp’s design allows for easy installation and removal, facilitating maintenance and adjustments as needed 1.

Air Crossover Connection

For air crossover connections, the V Band Clamp plays a significant role in linking the air intake systems between multiple cylinders or turbochargers. This connection is vital for balanced air distribution, which is essential for optimal combustion and engine efficiency. The clamp’s ability to maintain a tight seal under varying pressure conditions ensures consistent air flow, contributing to stable engine operation 2.

Turbocharger Gasket Kit

When integrated into a turbocharger gasket kit, the V Band Clamp enhances the sealing capabilities of the gaskets. It ensures that the connections between the turbocharger and the exhaust manifold, as well as the intake system, remain leak-free. This is particularly important in high-performance engines where even minor leaks can lead to significant power loss and inefficient operation 3.

Turbocharger Kit

In a comprehensive turbocharger kit, the V Band Clamp is used to secure various components such as the intercooler pipes, boost tubes, and other critical connections. Its role here is to provide a durable and reliable seal that can withstand the high pressures and temperatures associated with turbocharged engines. This ensures that the turbocharger system operates efficiently, delivering the desired boost without compromising on safety or performance 4.

Conclusion

The 4898590 V Band Clamp by Cummins is a critical component in ensuring the secure and efficient operation of commercial truck engines. Its robust design, ease of installation, and reliable sealing capabilities make it an essential part for maintaining the integrity and performance of various engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring optimal engine performance and longevity.

-

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ ↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ ↩ ↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ ↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.