3529852

V Band Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding The Cummins 3529852 V Band Clamp: A Comprehensive Guide

Introduction to V Band Clamps

V band clamps are essential components in various industrial and commercial applications, especially in commercial truck engines. These clamps create a tight seal between two surfaces, preventing fluid or gas leaks. Named for their V-shaped cross-section, these bands exert pressure on the seal to ensure a secure fit 2.

How a V Band Clamp Works

A V band clamp consists of a V-shaped band, a bolt, and a nut. Typically made from durable materials like stainless steel, the band provides strength and flexibility. The bolt and nut tighten the band around the seal, creating a secure, leak-proof connection. The V-shaped design ensures even pressure distribution across the seal, resulting in a consistent and reliable seal 2.

The Purpose of the Cummins 3529852 V Band Clamp

The Cummins 3529852 V band clamp is designed for commercial truck engines. Its primary function is to create a tight seal between components such as hoses, pipes, and fittings, preventing leaks and ensuring efficient engine operation. By maintaining a secure seal, this Cummins part helps prevent fluid or gas loss, which can lead to decreased performance and safety hazards 1.

Role of the 3529852 V Band Clamp in Truck Operations

In commercial truck operations, the 3529852 V band clamp is crucial for maintaining the integrity of the engine’s cooling, fuel, and exhaust systems. Ensuring these systems remain sealed and leak-free helps maintain optimal engine performance, reduce breakdown risks, and extend engine lifespan 1.

Troubleshooting and Maintenance

Proper maintenance and troubleshooting of the 3529852 V band clamp are vital for its effectiveness. Regular inspections should check for wear, corrosion, or damage to the clamp, bolt, or nut. Immediate replacement is necessary if any issues are detected to prevent leaks and maintain engine performance.

Following proper tightening procedures when installing the 3529852 V band clamp is also crucial. Over-tightening can damage the seal or clamp, while under-tightening can cause leaks. Using a torque wrench to tighten the clamp to the manufacturer’s specified torque settings is recommended 2.

Cummins: A Leader in Commercial Truck Parts

Cummins is a globally recognized leader in designing and manufacturing commercial truck parts, including the 3529852 V band clamp. With a commitment to quality, innovation, and customer satisfaction, Cummins has earned the trust of professionals in the commercial truck industry worldwide. Using Cummins parts ensures high-quality, reliable components for safe and efficient vehicle operation 1.

Expert Insights and Recommendations

Understanding the importance of proper maintenance and troubleshooting for components like the 3529852 V band clamp is essential. Following best practices and using high-quality parts from trusted manufacturers like Cummins helps ensure the longevity and performance of commercial trucks. Regular inspections, proper tightening procedures, and prompt replacement of damaged or worn components are key to maintaining a secure and leak-free seal in the engine and other critical systems 2.

Applications of the Cummins 3529852 V Band Clamp

The V Band Clamp part 3529852 by Cummins is designed to fit various engine models. It is commonly used in applications requiring a secure, leak-proof seal, such as in exhaust systems and other fluid connections.

Engines Utilizing the V Band Clamp

- 6B5.9, G855, G855 CM558, GTA855 CM558 (CM2358) G101, QSB5.9 CM850, QSB6.7 CM850 (CM2850), QSB6.7 M CM2250, QSB7 CM2880 B117, QSC8.3 CM850 (CM2850), QSG12/X12 CM2350 G110, and QSK60 CM850 MCRS: Ensures a tight seal around pipes and fittings, preventing leaks and maintaining system integrity.

- ISBE CM2150, ISBE4 CM850, ISG12 CM2880 G107, ISM CM570, ISM CM570/870, ISM CM876, ISM11 CM876 SN, ISX CM570, ISX CM870, ISX15 CM2250 SN, ISZ13 CM2150 Z105, M11 CELECT, and M11 CELECT PLUS: Provides a reliable connection for exhaust and fluid lines.

- N14 G: Ensures all connections are secure and leak-free, crucial for maintaining optimal engine performance and efficiency.

Role of the 3529852 V Band Clamp in Engine Systems

The 3529852 V Band Clamp is essential in assembling and maintaining various engine systems, particularly those involving turbochargers and exhaust systems. Its application ensures secure and efficient connections.

Turbocharger Systems

In turbocharger systems, the V Band Clamp connects the turbine housing to the exhaust outlet connection. This secure fitting is vital for maintaining exhaust flow integrity, directly impacting turbocharger performance. Whether for aftermarket turbochargers or incomplete turbochargers requiring a repair kit, the V Band Clamp ensures a leak-free connection, fundamental for optimal turbocharger operation.

Exhaust Systems

For exhaust systems, the V Band Clamp significantly connects various exhaust pipework sections. This includes connections to the turbocharger housing and other exhaust components. The clamp’s design allows for easy installation and removal, facilitating maintenance and upgrades with aftermarket parts or a housing repair kit.

Performance and Service Kits

When integrating performance parts or conducting maintenance with a service kit, the V Band Clamp is often included in the turbocharger gasket kit or as part of a V Band Clamp kit. Its use in these kits ensures all connections within the turbocharger and exhaust system are secure, contributing to the engine’s overall efficiency and performance.

Connecting Rod and Camshaft Applications

Although primarily associated with turbocharger and exhaust applications, the principles of secure and efficient connection provided by the V Band Clamp can be extended to other engine components like the connecting rod and camshaft. In specialized applications, it may secure custom or aftermarket components, ensuring they are firmly in place and operating as intended.

Crosshead and Turbine Housing

In more complex engine setups, the V Band Clamp might also connect the crosshead to the turbine housing or other critical junctions within the engine system. This application underscores the clamp’s versatility in ensuring robust connections across various engine components.

The 3529852 V Band Clamp’s role in these engine systems highlights its importance in maintaining secure, efficient, and leak-free connections, essential for engine performance and longevity.

Conclusion

The Cummins 3529852 V Band Clamp is a critical component in commercial truck engines, ensuring secure and leak-free connections in various engine systems. Proper maintenance, troubleshooting, and the use of high-quality parts from trusted manufacturers like Cummins are essential for the longevity and performance of commercial trucks. Regular inspections, proper tightening procedures, and prompt replacement of damaged components are key to maintaining a secure and leak-free seal in the engine and other critical systems.

SPECIFICATIONS

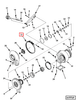

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Turbocharger Heat Shield | 1 | 3529846 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.