5294270

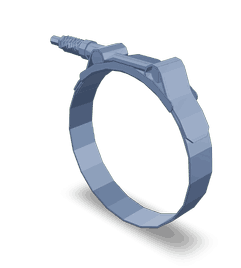

T Bolt Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The T Bolt Clamp 5294270, manufactured by Cummins, is a critical component in the commercial truck industry. This clamp is essential for securing various components and systems in commercial trucks, ensuring efficient and safe vehicle operation.

Basic Concepts of T Bolt Clamps

T Bolt Clamps are mechanical fasteners designed to secure components in various systems. They consist of a T-shaped bolt that threads into a corresponding nut, creating a clamping force that holds parts together. These clamps are commonly used in mechanical systems to secure hoses, pipes, and other components, ensuring they remain in place and function correctly under operational conditions 1.

Role of T Bolt Clamp 5294270 in Truck Operation

This Cummins part is integral to the operation and maintenance of commercial trucks. It is applied in various truck systems, including the fuel system, exhaust system, and cooling system, where it secures hoses and pipes. By maintaining the integrity of these connections, the clamp contributes to the overall reliability and performance of the truck 2.

Key Features of T Bolt Clamp 5294270

The T Bolt Clamp 5294270 is characterized by several key features that enhance its functionality. It is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. The design includes a T-shaped bolt that provides a strong clamping force, and the clamp is engineered to be easy to install and remove, facilitating maintenance procedures.

Benefits of Using T Bolt Clamp 5294270

Incorporating this part into truck maintenance and repair offers several advantages. Its durable construction ensures long-term reliability, while its design allows for easy installation, reducing downtime during maintenance. Additionally, the secure fitting provided by the clamp enhances the performance of the systems it is part of, contributing to the overall efficiency of the truck 3.

Installation Process

Installing the T Bolt Clamp 5294270 involves several steps to ensure a secure fitting. First, the components to be clamped are positioned correctly. Then, the T-shaped bolt is threaded into the corresponding nut, gradually increasing the clamping force until the desired tension is achieved. Tools required may include a wrench for tightening the bolt. Best practices include ensuring the clamp is aligned correctly and that the clamping force is even to prevent damage to the components.

Troubleshooting Common Issues

Common problems associated with T Bolt Clamps include leaks or loosening over time. To address these issues, regular inspections are recommended to identify any signs of wear or damage. If a leak is detected, the clamp should be tightened or replaced as necessary. For loosening, re-tightening the clamp or investigating the cause of the loosening, such as vibration or thermal expansion, may be required.

Maintenance Tips

To ensure the longevity and optimal performance of the T Bolt Clamp 5294270, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or damage. Cleaning the clamp and its components can prevent buildup that may affect performance. Following the manufacturer’s guidelines for torque settings during installation also contributes to the clamp’s effectiveness.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of T Bolt Clamp 5294270 in Aftertreatment Systems

This part is integral to the secure assembly and maintenance of various components within aftertreatment systems. Its primary function is to ensure a tight and reliable connection between different parts, which is essential for the efficient operation of the system.

In an aftertreatment device, the T Bolt Clamp is often used to connect the exhaust pipe to the catalytic converter. This connection must be leak-free to maintain the integrity of the exhaust flow and ensure that all emissions are properly treated before being released into the atmosphere. The clamp’s design allows for easy installation and removal, facilitating routine maintenance and inspections.

Within the aftertreatment system, the T Bolt Clamp may also be employed to secure sensors and monitoring devices. These components are vital for measuring the efficiency of the aftertreatment processes and ensuring that the system operates within specified parameters. A secure connection provided by the T Bolt Clamp helps prevent sensor malfunctions due to vibrations or loose fittings.

Additionally, the clamp plays a role in connecting various sections of the aftertreatment device, such as the diesel particulate filter (DPF) to the selective catalytic reduction (SCR) system. This ensures that exhaust gases flow seamlessly through the treatment stages, enhancing the overall effectiveness of the system in reducing harmful emissions.

The robust nature of the T Bolt Clamp also contributes to the durability of the aftertreatment system. By withstanding high temperatures and corrosive environments, it helps maintain the structural integrity of the connections over the lifespan of the engine system. This reliability is particularly important in heavy-duty applications where the aftertreatment system is subjected to rigorous conditions.

Conclusion

The T Bolt Clamp 5294270 by Cummins is a vital component in the commercial truck industry, ensuring the secure and reliable operation of various systems. Its durable construction, ease of installation, and maintenance benefits make it an essential part for truck maintenance and repair. Regular maintenance and proper installation practices are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.