554013

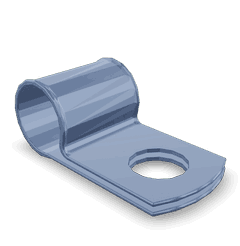

Tube Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 554013 Tube Clamp is a component designed for use in commercial trucks. It serves to secure and connect tubes and hoses within various systems of the vehicle. A tube clamp, in general, is a device used to hold tubing in place, ensuring a secure and leak-free connection. In the automotive industry, tube clamps are utilized in a variety of applications, including fuel lines, exhaust systems, and hydraulic lines, to name a few 1.

Basic Concepts of Tube Clamps

Tube clamps operate on the principle of compression to secure tubes and hoses. They typically consist of a band that wraps around the tube and a mechanism to tighten the band, creating a firm grip. Materials commonly used in tube clamps include stainless steel, aluminum, and various types of rubber or polymer for the band. These materials are chosen for their durability, resistance to corrosion, and ability to maintain a tight seal under varying conditions 2.

Purpose of the Cummins 554013 Tube Clamp

This Cummins part is specifically designed to play a role in the secure connection of tubes within a truck’s systems. It is commonly used with fuel lines, exhaust systems, and hydraulic lines. By providing a reliable connection, it helps ensure the efficient operation of these systems, contributing to the overall performance and safety of the truck.

Key Features

The 554013 features a design that includes a durable band and a tightening mechanism that allows for easy adjustment. It is constructed from materials that offer resistance to corrosion and wear, enhancing its performance and longevity. Unique attributes of this clamp may include a design that allows for easy installation and adjustment, contributing to its effectiveness in securing tubes.

Benefits

Using this part offers several advantages. It provides improved reliability in tube connections, which is vital for the safe and efficient operation of a truck. The ease of installation and adjustment of the clamp can save time during maintenance procedures. Additionally, its durable construction contributes to reduced maintenance needs and prolonged service life, enhancing the overall efficiency and safety of the truck.

Installation Process

To install the 554013, first, ensure the tube is clean and free of any debris. Place the clamp around the tube and use the tightening mechanism to secure it in place. It is important to achieve the correct tension to ensure a leak-free connection without damaging the tube. Following the manufacturer’s guidelines for installation will help ensure a secure and effective connection.

Troubleshooting and Maintenance

Common issues with tube clamps may include leaks or loose connections. To troubleshoot, check the clamp for proper tension and ensure the tube is not damaged. Regular maintenance, such as inspecting for signs of wear or corrosion, can help prolong the life of the clamp. If signs of damage are present, replacement may be necessary to ensure continued reliable performance.

Compatibility and Applications

The 554013 is compatible with a variety of tubes and systems within commercial trucks. It is used in applications where secure and reliable tube connections are required, such as in fuel lines, exhaust systems, and hydraulic lines.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s components, including the 554013, are trusted by professionals for their performance and durability. Cummins’ commitment to innovation and quality has made it a leader in the industry, providing solutions that meet the demanding requirements of commercial trucking.

Tube Clamp 554013 Compatibility with Cummins Engines

The Tube Clamp 554013, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engines. This clamp is essential for securing and maintaining the integrity of various tubes and hoses within the engine system. Below is a detailed breakdown of its compatibility across different engine models:

ISC Series Engines

- ISC CM554

- ISC CM850

These engines, part of the ISC series, utilize the Tube Clamp 554013 to secure critical tubes and hoses, ensuring proper fluid flow and preventing leaks.

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The ISL series engines, including the ISL CM554, ISL9 CM2150 SN, and ISL9.5 CM2880 L138, also benefit from the Tube Clamp 554013. This clamp is crucial for maintaining the structural integrity of the engine’s tubing system.

ISB Series Engines

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

The ISB series engines, including the ISB CM550, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, and ISB5.9 CM2880 B149, all incorporate the Tube Clamp 554013. This clamp is essential for securing various tubes and hoses, ensuring the engine operates efficiently and reliably.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, such as the ISBE CM2150, ISBE CM800, and ISBE4 CM850, also use the Tube Clamp 554013. This clamp is vital for maintaining the structural integrity of the engine’s tubing system.

Other Engines

- ISD4.5 CM2220 D108

- ISF3.8 CM2220 AN

The Tube Clamp 554013 is also compatible with the ISD4.5 CM2220 D108 and ISF3.8 CM2220 AN engines, ensuring that the tubes and hoses within these systems are securely fastened.

This comprehensive compatibility ensures that the Tube Clamp 554013 is a reliable choice for securing tubes and hoses across a wide range of Cummins engines.

Role of Part 554013 Tube Clamp in Engine Systems

The Part 554013 Tube Clamp is an essential component in securing and maintaining the integrity of various tubing systems within engine assemblies. Its application spans across multiple subsystems, ensuring efficient operation and durability.

Compressor and Cooling Systems

In compressor cooling systems, the Tube Clamp is utilized to secure the compressor cooling tubes and the compressor tube mounting brace. This ensures that the tubes remain firmly in place, preventing leaks and maintaining the efficiency of the cooling process. The clamp also plays a role in securing the compressor water outlet tube, which is vital for dissipating heat from the compressor.

Fuel Systems

Within fuel systems, the Tube Clamp is employed to hold the fuel tubes in both automatic and variable speed applications. It ensures that the fuel supply lines are securely fastened, reducing the risk of fuel leaks and maintaining consistent fuel delivery to the engine. Additionally, it is used in conjunction with the fuel system RB drain and fuel drain mounting to ensure proper drainage and prevent fuel accumulation, which could lead to engine malfunctions.

Oil Systems

For oil systems, the Tube Clamp is crucial in securing the oil gauge and mounting tube, as well as the oil gauge tube mounting. This ensures accurate oil level readings and prevents oil leaks, which are essential for maintaining engine lubrication and performance. The clamp also plays a role in securing the dipstick and tube, along with the dipstick tube hardware, ensuring that the dipstick remains in proper position for accurate oil level checks.

Turbocharger and Plumbing Systems

In turbocharger applications, the Tube Clamp is used to secure the mounting turbocharger and the turbocharger outlet tube. This ensures that the turbocharger is properly mounted and that the outlet tube is securely fastened, which is essential for optimal turbocharger performance and durability.

Additionally, the clamp is used in plumbing applications for both fuel and turbocharger systems. It ensures that all plumbing connections are secure, preventing leaks and maintaining the integrity of the fuel and turbocharger systems.

Radiator and Corrosion Resistance

The Tube Clamp also plays a role in securing the radiator tubes and ensuring that the corrosion resistor is properly mounted. This helps in maintaining the efficiency of the radiator and protecting the engine from corrosion, which can lead to decreased performance and increased maintenance costs.

Overall Application

Overall, the Part 554013 Tube Clamp is a versatile component that enhances the reliability and performance of various engine systems by ensuring that all tubing connections are secure and leak-free. Its application across different subsystems underscores its importance in maintaining the overall efficiency and durability of engine assemblies.

Conclusion

The Cummins 554013 Tube Clamp is a critical component in the maintenance and operation of commercial trucks. Its role in securing and maintaining the integrity of various tubing systems within engine assemblies cannot be overstated. From compressor and cooling systems to fuel, oil, turbocharger, and radiator systems, this part ensures efficient operation and durability across a wide range of applications. Its compatibility with various Cummins engines further highlights its versatility and importance in the commercial trucking industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.