This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 5284618 T-Bolt Clamp, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This clamp is specifically designed for commercial trucks, ensuring the secure attachment of various mechanical components.

Basic Concepts of T-Bolt Clamps

A T-Bolt Clamp is a fastener used in mechanical systems to hold components in place. It consists of a bolt with a T-shaped head that fits into a slot on the clamp body, allowing for secure and adjustable clamping. This mechanism applies pressure to the components, ensuring they remain firmly in position under operational conditions 1.

Purpose of the 5284618 T-Bolt Clamp in Truck Operations

In commercial trucks, the 5284618 T-Bolt Clamp secures hoses, pipes, and other components within the truck’s mechanical systems. It maintains the integrity of these connections, preventing loosening or disconnection during operation, which could lead to system failures or inefficiencies 2.

Key Features of the 5284618 T-Bolt Clamp

The 5284618 T-Bolt Clamp is engineered with specific design elements and materials to enhance its effectiveness and durability. It features a robust construction capable of withstanding the rigors of commercial truck environments. The materials used are chosen for their strength and resistance to wear and corrosion, contributing to the clamp’s longevity and reliability 3.

Benefits of Using the 5284618 T-Bolt Clamp

The advantages of using the 5284618 T-Bolt Clamp include improved security of connections, ease of installation, and maintenance efficiency. Its design allows for quick and easy adjustments, ensuring a snug fit without the need for complex tools. Additionally, the clamp’s durability reduces the frequency of replacements, contributing to overall maintenance efficiency 4.

Installation Process

To install the 5284618 T-Bolt Clamp correctly, position the clamp around the components to be secured. Insert the T-Bolt through the clamp and into the slot, then tighten the bolt to achieve the desired clamping pressure. Ensure the clamp is evenly tightened to avoid uneven pressure distribution, which could lead to component damage or failure.

Common Applications

The 5284618 T-Bolt Clamp is commonly used in various parts of a truck’s mechanical systems, including the attachment of hoses in the cooling system, securing of pipes in the fuel system, and fastening of components in the engine compartment. Its versatility makes it a valuable component in maintaining the structural and operational integrity of commercial trucks.

Troubleshooting and Maintenance

To ensure the longevity and effectiveness of the 5284618 T-Bolt Clamp, regular inspections should be conducted to check for signs of wear, corrosion, or loosening. If any issues are identified, they should be addressed promptly to prevent further damage. Routine maintenance practices, such as cleaning and lubricating the clamp, can also help prolong its lifespan.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and approximately 7,400 dealer locations. Cummins’ product range includes engines, related technologies, and complete power systems for on- and off-highway applications.

Cummins T-Bolt Clamp Part 5284618 Compatibility

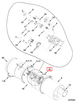

The Cummins T-Bolt Clamp part number 5284618 is designed to fit seamlessly within the engine configurations of the QSL9 CM2250 and QSL9 CM2350 L102. This part is integral to the engine’s assembly, ensuring secure fastening and stability of various components.

QSL9 CM2250

In the QSL9 CM2250 engine, the T-Bolt Clamp part 5284618 is utilized in several critical areas. It is often employed to secure engine mounts, ensuring that the engine remains firmly anchored within the vehicle’s chassis. Additionally, it plays a role in fastening components within the engine’s internal structure, contributing to the overall integrity and performance of the engine.

QSL9 CM2350 L102

Similarly, in the QSL9 CM2350 L102 engine, the T-Bolt Clamp part 5284618 is essential for maintaining the structural integrity of the engine. It is used to fasten various engine mounts and internal components, ensuring that all parts are securely held in place. This is particularly important in high-performance engines like the QSL9 CM2350 L102, where precision and reliability are paramount.

By utilizing the T-Bolt Clamp part 5284618, both the QSL9 CM2250 and QSL9 CM2350 L102 engines benefit from enhanced stability and durability, ensuring optimal performance and longevity.

Role of Part 5284618 T-Bolt Clamp in Engine Systems

The 5284618 T-Bolt Clamp is a critical component in securing various elements within engine systems, particularly in the context of aftertreatment devices. This clamp ensures a stable and reliable connection between the aftertreatment device and the exhaust system, facilitating efficient operation and maintenance.

Integration with Aftertreatment Devices

In modern engine systems, aftertreatment devices such as Diesel Particulate Filters (DPFs), Selective Catalytic Reduction (SCR) systems, and Exhaust Gas Recirculation (EGR) coolers are vital for meeting emissions standards. The 5284618 T-Bolt Clamp plays a significant role in these systems by:

- Securing Connections: It firmly attaches the aftertreatment device to the exhaust pipe, ensuring that there are no leaks in the exhaust flow. This is important for maintaining the efficiency of the aftertreatment processes.

- Facilitating Maintenance: The clamp allows for easy removal and reinstallation of the aftertreatment device, which is beneficial during routine maintenance or when upgrades are necessary.

- Withstanding High Temperatures: Designed to endure the high temperatures typical in exhaust systems, the clamp ensures a durable and long-lasting connection.

Enhancing System Performance

The reliable attachment provided by the 5284618 T-Bolt Clamp contributes to the overall performance of the engine system. By ensuring a secure fit, it helps in:

- Optimizing Exhaust Flow: A leak-free connection ensures that exhaust gases pass through the aftertreatment device efficiently, enhancing its filtering and conversion capabilities.

- Reducing Vibrations: The clamp minimizes vibrations between the aftertreatment device and the exhaust system, which can otherwise lead to wear and tear or disconnections.

- Supporting Thermal Management: It aids in managing thermal expansion and contraction, which are common in high-temperature environments, thereby prolonging the lifespan of connected components.

Application in Complex Systems

In more complex engine systems that incorporate multiple aftertreatment devices, the 5284618 T-Bolt Clamp is used extensively to connect various components such as:

- DPF to SCR System: Ensuring a tight seal between these two critical components.

- EGR Cooler to Exhaust Manifold: Providing a robust connection that can withstand the pressures and temperatures involved.

- Sensor Mounting: Securing sensors that monitor the performance of aftertreatment devices, ensuring accurate readings and system diagnostics.

By understanding the role of the 5284618 T-Bolt Clamp in these applications, engineers and mechanics can better appreciate its importance in maintaining the integrity and efficiency of engine systems.

Conclusion

The 5284618 T-Bolt Clamp by Cummins is a vital component in the automotive and heavy-duty truck industry. Its robust design, ease of installation, and maintenance efficiency make it an indispensable part of commercial truck operations. By ensuring secure connections and facilitating efficient maintenance, this Cummins part contributes significantly to the reliability and performance of engine systems.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.