This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

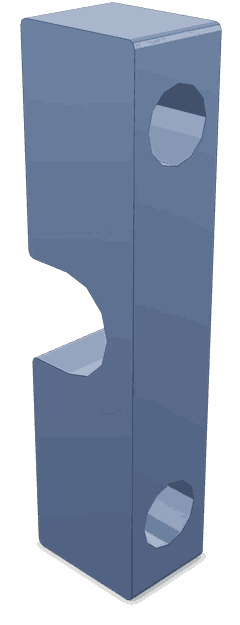

The 4999824 Tube Clamp Assembly is a component designed for use in commercial truck operations. It serves a vital function in securing and maintaining the integrity of fluid systems within these vehicles. Understanding its purpose and significance is key to ensuring the efficient and reliable operation of commercial trucks.

Basic Concepts of Tube Clamp Assembly

A Tube Clamp Assembly is a device used to secure and connect tubes in fluid systems. Its general function is to provide a secure, leak-proof connection that can withstand the pressures and temperatures encountered in these systems. In the context of a commercial truck, the Tube Clamp Assembly ensures that fluid lines, such as those for fuel, coolant, and hydraulic systems, remain intact and function correctly under various operating conditions 1.

Purpose of the 4999824 Tube Clamp Assembly

This Cummins part plays a specific role in the operation of a truck by securing various fluid lines. It is applied in systems such as fuel delivery, coolant circulation, and hydraulic controls. By providing a reliable connection, it helps maintain the performance and safety of these systems, ensuring that fluids are delivered efficiently and without leakage 2.

Key Features

The 4999824 Tube Clamp Assembly is characterized by several primary features that enhance its performance and durability. It is composed of materials that offer resistance to corrosion and high temperatures, ensuring longevity in demanding environments. The design includes elements that allow for easy installation and adjustment, facilitating secure tube connections. Unique characteristics may include specialized clamps or fittings that provide additional stability and leak prevention 3.

Benefits

The advantages of using this part include improved reliability in fluid system connections, which contributes to the overall efficiency of the truck. Its design allows for ease of installation, reducing downtime during maintenance procedures. Additionally, the assembly offers maintenance benefits, such as simplified inspection and replacement processes, which can help in prolonging the service life of the fluid systems it supports.

Installation Process

Installing the 4999824 Tube Clamp Assembly involves several steps to ensure a secure fit. The process begins with the proper preparation of the tube ends, followed by positioning the clamp over the tube and tightening it to the specified torque. Tools required may include a torque wrench for precise tightening. Best practices include verifying the alignment of the tube within the clamp and ensuring that all connections are free from debris to prevent leaks.

Troubleshooting Common Issues

Common problems associated with Tube Clamp Assemblies can include signs of wear, leakage, and improper installation. Addressing these issues may involve inspecting the clamp for damage, ensuring that all connections are tight and aligned correctly, and replacing worn or damaged components as necessary. Regular checks can help identify potential issues before they lead to system failures.

Maintenance Tips

To prolong the life of the 4999824 Tube Clamp Assembly, regular maintenance practices are recommended. This includes periodic inspection of the clamp and tube connections for signs of wear or leakage. Cleaning the assembly to remove any buildup that could affect its performance is also advised. Following manufacturer guidelines for inspection intervals and maintenance procedures can help ensure the continued reliability of the fluid systems.

Compatibility and Applications

The 4999824 Tube Clamp Assembly is designed for use in a variety of trucks and fluid systems, demonstrating its versatility and widespread application in the industry. Its compatibility with different tube sizes and materials makes it a valuable component in maintaining the integrity of fluid lines in commercial vehicles.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history of innovation and customer-focused solutions underscores the quality and dependability of components like the 4999824 Tube Clamp Assembly. Cummins’ reputation in the industry is built on a foundation of excellence in engineering and manufacturing, ensuring that their products meet the high standards required for commercial truck operations.

Compatibility with Cummins Engines

This part is engineered to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability.

ISX12/ISX11.9 CM2250 Engines

The ISX12 and ISX11.9 CM2250 engines are high-performance models, often utilized in heavy-duty applications. The Tube Clamp Assembly is integral to these engines, providing the necessary support and alignment for the coolant, fuel, and other critical fluid lines. Its robust design ensures that the clamps maintain a tight grip, preventing leaks and ensuring efficient operation.

ISZ13 CM2150 Z105 Engine

The ISZ13 CM2150 Z105 engine is another robust Cummins model, designed for demanding applications. The Tube Clamp Assembly for this engine is specifically tailored to fit the unique layout and requirements of the ISZ13 series. It ensures that all fluid lines are securely fastened, contributing to the engine’s overall durability and performance.

QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 Engines

The QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines are part of Cummins’ lineup of advanced, high-efficiency engines. These models are designed to meet stringent emission standards while delivering exceptional power and reliability. The Tube Clamp Assembly for these engines is engineered to provide precise and reliable clamping, ensuring that the engine’s fluid systems operate without issues. Its design allows for easy installation and maintenance, making it a vital component for these sophisticated engines.

Each of these engines benefits from the Tube Clamp Assembly’s ability to maintain the integrity of the engine’s fluid systems, ensuring that performance remains consistent and reliable over time.

Role in Engine Systems

The Tube Clamp Assembly, part number 4999824, is an essential component in the securement and maintenance of various engine systems, particularly those involving fluid dynamics and high-pressure environments. This assembly is integral in the injector plumbing system, where it ensures the integrity and stability of connections between the injector and the plumbing network.

In the context of injector plumbing, the Tube Clamp Assembly serves to firmly hold the tubes in place, preventing any unwanted movement or disconnection that could lead to leaks or system failure. It is designed to withstand the high pressures and temperatures typically encountered in engine systems, ensuring a reliable seal around the tubes.

Furthermore, within the broader plumbing system of the engine, the Tube Clamp Assembly plays a similar role. It secures the connections between various components, maintaining the structural integrity of the system and ensuring that fluids are transported efficiently and without loss.

The assembly’s application extends to the injector itself, where it is used to secure the injector to the plumbing, ensuring that the injector operates within the designed parameters. This is particularly important in high-performance engines where precision and reliability are paramount.

Conclusion

In summary, the Tube Clamp Assembly, part number 4999824, is a key component in maintaining the structural and operational integrity of engine systems, particularly in the areas of injector plumbing, general plumbing, and injector connections. Its role in securing and stabilizing these connections is fundamental to the efficient and safe operation of the engine.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.