This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

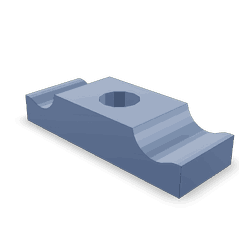

The Cummins 4978841 Tube Clamp is a component designed to secure and maintain the integrity of tubing systems in commercial trucks. Its role is significant in ensuring the reliable operation of these vehicles, particularly in environments where tubing systems are subject to stress and vibration.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubes in place, ensuring secure connections in various systems. They function by applying pressure around the tube, creating a tight seal that prevents leaks and maintains the structural integrity of the tubing system. In automotive and industrial settings, tube clamps are utilized in fuel lines, brake systems, and other fluid transport applications 1.

Purpose of the Cummins 4978841 Tube Clamp

This Cummins part is specifically designed to secure and maintain the integrity of tubing systems in commercial trucks. It plays a role in ensuring that connections remain tight and leak-free, which is vital for the safe and efficient operation of the vehicle. By securing tubing, it helps prevent fluid leaks, which can lead to system failures or safety hazards.

Key Features

The 4978841 features a durable material composition, typically made from high-strength materials to withstand the rigors of commercial truck environments. Its design includes elements that enhance grip and sealing capabilities, ensuring a secure fit around the tubing. Unique attributes may include corrosion-resistant coatings and adjustable mechanisms for a custom fit.

Benefits of Using the Cummins 4978841 Tube Clamp

Utilizing this part offers several advantages. It contributes to improved safety by ensuring secure tubing connections, reducing the risk of leaks. Reliability is enhanced as the clamp maintains a consistent seal under various conditions. Efficiency is also improved, as secure connections minimize the need for frequent maintenance or repairs.

Installation Process

Installing the 4978841 involves several steps. First, ensure the tubing is clean and free of debris. Position the clamp around the tubing and use the appropriate tools to tighten it securely. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which can damage the tubing, or under-tightening, which can lead to leaks 2.

Troubleshooting Common Issues

Common issues with tube clamps include leaks, loose connections, and corrosion. To address leaks, inspect the clamp and tubing for damage and ensure the clamp is properly tightened. Loose connections can often be resolved by re-tightening the clamp. Corrosion may require cleaning the affected areas and applying a corrosion-resistant coating.

Maintenance Tips

Regular maintenance of the 4978841 is important for longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the clamp and tubing to remove debris, and reapplying any protective coatings as needed. Following a scheduled maintenance plan can help prevent issues before they become critical.

Safety Considerations

When installing, maintaining, or troubleshooting the 4978841, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the vehicle is properly supported, and following all manufacturer recommendations to prevent accidents and ensure compliance with industry standards 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its innovative solutions and commitment to quality. The company offers a wide range of products for various industries, including commercial trucks, where reliability and performance are paramount.

Role of Part 4978841 Tube Clamp in Engine Systems

The 4978841 is an essential component in securing and maintaining the integrity of various engine systems, particularly in the fuel and filtration components.

In the fuel system, the Tube Clamp ensures a secure connection between the fuel lines and the fuel filter. This connection is vital for maintaining consistent fuel pressure and preventing leaks, which could lead to engine performance issues or safety hazards. By clamping the fuel lines firmly in place, it ensures that the fuel delivery remains uninterrupted and efficient, contributing to optimal engine operation.

In the filtration system, the Tube Clamp plays a similar role by securing the connections between the filter housing and the associated pipes or hoses. This is important for maintaining the structural integrity of the filtration system, ensuring that contaminants are effectively filtered out of the fuel before it reaches the engine. A secure connection prevents any bypass of unfiltered fuel, which could otherwise lead to engine wear or damage over time.

Overall, the 4978841 is integral to the reliable operation of both the fuel and filtration systems within an engine, ensuring that all connections are tight, secure, and leak-free.

Conclusion

The Cummins 4978841 Tube Clamp is a vital component in the maintenance and operation of commercial truck engines. Its role in securing and maintaining the integrity of tubing systems ensures the reliable and safe operation of these vehicles. By understanding its purpose, features, and benefits, as well as following proper installation, maintenance, and safety procedures, one can ensure the optimal performance and longevity of this essential part.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.