4965329

t Bolt Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The T Bolt Clamp 4965329, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This clamp is essential for the operational efficiency and safety of commercial trucks, offering robust construction and reliable performance to maintain the structural integrity of various truck components.

Purpose and Function

The primary function of the T Bolt Clamp 4965329 is to secure components within the truck’s system, ensuring they remain firmly in place under various operational conditions. This stable connection is vital for the overall structural integrity of the truck, contributing to safe and efficient operation. The clamp is particularly beneficial in scenarios where components are subject to vibration or movement, helping to prevent potential issues that could arise from unsecured parts.

Key Features

This Cummins part is characterized by its durable design and high-quality material composition. It is engineered to withstand the rigors of commercial truck operations, providing a reliable solution for component securing. Notable attributes of this clamp include its ease of installation, allowing for quick and efficient setup, and its robust construction, ensuring long-lasting performance even in demanding environments.

Benefits

Utilizing the T Bolt Clamp 4965329 in truck maintenance and operation offers several advantages. It enhances safety by ensuring components are securely fastened, reducing the risk of accidents caused by loose parts. Additionally, its reliable performance contributes to the overall efficiency of truck operations, minimizing downtime and maintenance costs. The clamp’s design also facilitates easier access for inspections and repairs, further contributing to the truck’s reliability.

Installation Process

Proper installation of the T Bolt Clamp 4965329 is crucial for its effective performance. The process involves selecting the appropriate location for the clamp, ensuring the components to be secured are clean and free of debris, and then positioning the clamp around the components. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the clamp is tightened to the correct level, providing a secure fit without over-tightening, which could damage the components or the clamp itself 1.

Maintenance Tips

To ensure the T Bolt Clamp 4965329 maintains its optimal performance and longevity, regular inspections are recommended. These should check for any signs of wear, corrosion, or damage. Lubricating the clamp and its components periodically can also help maintain its efficiency and prevent issues related to friction or seizing. Addressing any identified issues promptly will help preserve the clamp’s functionality and contribute to the overall reliability of the truck 2.

Troubleshooting Common Issues

Common issues with the T Bolt Clamp 4965329 may include loosening over time due to vibration, corrosion in moist environments, or damage from improper installation. To address these issues, regular inspections can help identify problems early. If loosening is detected, re-tightening the clamp to the manufacturer’s specified torque can resolve the issue. Corrosion may require cleaning and possibly reapplying a protective coating. Damage from improper installation may necessitate replacement of the clamp.

Safety Considerations

When working with the T Bolt Clamp 4965329, it is important to follow safety precautions to prevent accidents and injuries. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Ensuring the truck is properly secured and the engine is off before beginning any work is also crucial. Additionally, following the manufacturer’s guidelines for installation and maintenance will help ensure safe and effective use of the clamp 3.

Cummins Overview

Cummins is a globally recognized leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a strong reputation for quality and innovation, Cummins has been serving the automotive and heavy-duty truck industries for many years. Their commitment to excellence is evident in their wide range of products, including the T Bolt Clamp 4965329, which is designed to meet the high standards of commercial truck operations.

Compatibility

The Cummins part 4965329, a T Bolt Clamp, is designed to fit seamlessly with the following engines:

- QSK60 CM2350 K116

- QSK60 CM2350 K117

- QSK60 CM2350 K136

This T Bolt Clamp is engineered to ensure a secure and reliable connection in these engines, maintaining the integrity of the system it is part of. Its compatibility with these specific engine models underscores its versatility and importance in the engine’s assembly and operation.

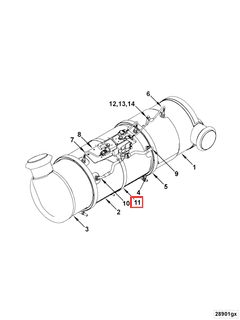

Role in Engine Systems

The t Bolt Clamp, identified by part number 4965329, is integral to the secure assembly and operation of various engine components. Specifically, it ensures the reliable connection and stability of components within the aftertreatment system, which is essential for maintaining efficient engine performance and emissions control.

Integration with Aftertreatment Devices

In the context of aftertreatment devices, the t Bolt Clamp plays a significant role in connecting exhaust pipes and catalytic converters. This secure attachment is vital for the proper flow of exhaust gases, which are treated to reduce harmful emissions before they are released into the atmosphere. The clamp’s robust design ensures that these connections remain intact under the high temperatures and pressures typical of exhaust systems.

Function in Decomposition Reactors

When it comes to decomposition reactors, the t Bolt Clamp is used to join sections of the reactor housing and connect them to the exhaust system. This is particularly important in reactors designed to break down harmful compounds in the exhaust stream. The clamp’s ability to withstand thermal expansion and contraction ensures that the reactor maintains its structural integrity and operational efficiency over time.

Application in Reactor Systems

In broader reactor systems, which may include various types of chemical reactors used in engine applications, the t Bolt Clamp facilitates the secure attachment of reactor components. This includes connecting inlet and outlet pipes, as well as ensuring that internal components are properly aligned and sealed. The clamp’s design allows for easy installation and removal, which is beneficial during maintenance or upgrades.

Ensuring Stability in Decomposition Processes

For decomposition processes within engine systems, the t Bolt Clamp is essential for maintaining the stability of connections between different sections of the decomposition apparatus. This stability is crucial for the consistent performance of decomposition reactions, which are often sensitive to changes in pressure and temperature. The clamp helps to mitigate these variables by providing a reliable and durable connection point.

Conclusion

In summary, the t Bolt Clamp (part 4965329) is a key component in the assembly and operation of various engine systems, particularly within aftertreatment devices, decomposition reactors, and broader reactor systems. Its role in ensuring secure and stable connections contributes significantly to the overall efficiency and reliability of these systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.