4965323

t Bolt Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The T Bolt Clamp, identified by part number 4965323, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This clamp is integral to the maintenance and operation of commercial trucks, ensuring secure connections within various systems. Cummins is renowned for its high-quality parts and comprehensive product offerings, making the T Bolt Clamp a reliable choice for truck maintenance professionals 1.

Basic Concepts and Functionality

The T Bolt Clamp is designed with a T-shaped bolt that threads into a corresponding T-slot. This design allows for a secure and adjustable connection, accommodating slight misalignments and vibrations that are common in truck operations. It operates by clamping two components together, ensuring a tight and stable connection that can withstand the rigors of commercial use 2.

Purpose of the T Bolt Clamp

In truck operations, the T Bolt Clamp serves to connect various components securely. It is commonly used in exhaust systems, fuel lines, and other critical systems where a reliable connection is necessary. Its application extends to different truck systems and components, enhancing overall performance and safety 3.

Key Features

The T Bolt Clamp is constructed from durable materials, typically steel or stainless steel, ensuring longevity and resistance to corrosion. Its design includes a T-shaped bolt and a corresponding T-slot, allowing for easy installation and adjustment. The clamp’s unique characteristics, such as its adjustable nature and robust construction, enhance its performance in demanding environments.

Benefits

The T Bolt Clamp offers several advantages in truck operations. It provides improved safety by ensuring secure connections, reducing the risk of leaks and failures. Its reliability enhances the overall efficiency of truck systems, contributing to smoother operations. Additionally, the clamp’s design allows for easy maintenance and adjustment, further improving its practicality in commercial settings.

Installation Process

Installing the T Bolt Clamp involves threading the T-shaped bolt into the T-slot until the desired tension is achieved. It is important to follow best practices, such as ensuring the components are properly aligned and the clamp is tightened to the manufacturer’s specifications. Potential challenges include ensuring the clamp is not overtightened, which could damage the components, or under-tightened, which could lead to an insecure connection.

Maintenance and Troubleshooting

To ensure the longevity and performance of the T Bolt Clamp, regular maintenance is recommended. This includes checking for signs of wear or corrosion and ensuring the clamp remains securely tightened. Common issues such as leaks or loose connections can often be resolved by re-tightening the clamp or replacing worn components.

Compatibility and Usage

The T Bolt Clamp is compatible with a variety of trucks and systems, though specific compatibility and usage guidelines should be consulted for detailed information. It is designed to fit into different truck systems, providing a versatile solution for secure connections.

Safety Considerations

When installing, maintaining, or troubleshooting the T Bolt Clamp, it is important to follow safety protocols. This includes wearing appropriate personal protective equipment, ensuring the truck is properly supported, and following the manufacturer’s guidelines to prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins, the manufacturer of the T Bolt Clamp, has a rich history in the commercial truck industry. Founded in 1919, Cummins has grown to become a global leader in diesel engine manufacturing and related technologies. Their product offerings span a wide range of components and systems, all designed to enhance the performance, reliability, and efficiency of commercial trucks.

Cummins Engine Part 4965323: T Bolt Clamp Application

The Cummins part number 4965323, a T Bolt Clamp, is a critical component in the assembly and maintenance of several Cummins diesel engines. This part is integral to securing various parts and ensuring the structural integrity of the engine during operation.

Application in QSB6.7 CM2250 and QSL9 CM2250 Engines

The T Bolt Clamp part number 4965323 is used in both the QSB6.7 CM2250 and QSL9 CM2250 engines. These engines are part of Cummins’ lineup of industrial and commercial diesel engines, known for their reliability and efficiency. The clamp is employed in securing components that require robust fastening, ensuring that parts remain tightly secured under the operational stresses these engines endure.

Application in QSL9 CM2350 L102 Engine

In the QSL9 CM2350 L102 engine, the T Bolt Clamp part number 4965323 also plays a vital role. This engine is designed for heavy-duty applications, often found in construction and agricultural equipment. The clamp’s function here is to maintain the integrity of the engine’s components, ensuring that parts such as brackets, covers, and other structural elements are fastened securely. This is crucial for the longevity and performance of the engine, especially in demanding environments.

Importance of the T Bolt Clamp

The T Bolt Clamp is essential for the proper assembly and maintenance of these engines. Its design allows for a secure and tight fit, preventing loosening over time, which could lead to operational failures. The clamp’s application across these engines highlights its versatility and importance in Cummins’ engine design and maintenance protocols.

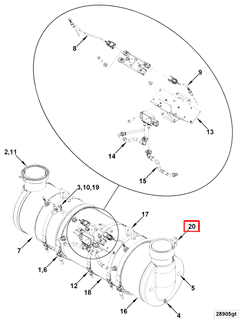

Role of Part 4965323 T Bolt Clamp in Engine Systems

The 4965323 T Bolt Clamp is an essential component in the assembly and functionality of various engine systems, particularly within the aftertreatment device framework. This clamp plays a significant role in securing and maintaining the integrity of connections between different components within the aftertreatment system.

Integration with Aftertreatment Device

In the aftertreatment device, the 4965323 T Bolt Clamp is utilized to ensure a tight and reliable connection between the device and the exhaust system. This connection is vital for the efficient flow of exhaust gases through the aftertreatment components, which include the Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) system, and other emission control devices. The clamp helps in minimizing leaks and ensuring that the aftertreatment system operates within optimal parameters.

Device Assembly

During the assembly of the aftertreatment device, the 4965323 T Bolt Clamp is employed to join various sections of the device. This includes connecting the inlet and outlet pipes to the main body of the aftertreatment device. The secure fit provided by the clamp is essential for withstanding the high temperatures and pressures experienced within the exhaust system, thereby enhancing the durability and performance of the aftertreatment device.

Aftertreatment System Maintenance

In maintenance procedures, the 4965323 T Bolt Clamp facilitates the disassembly and reassembly of the aftertreatment system components. Its design allows for easy removal and replacement, which is beneficial during routine inspections or when repairs are necessary. The clamp ensures that all connections are restored to their original tightness, maintaining the efficiency of the aftertreatment system.

Top-Level Assembly Aftertreatment

At the top-level assembly of the aftertreatment system, the 4965323 T Bolt Clamp contributes to the overall structural integrity of the system. It secures the aftertreatment device to the engine’s exhaust system, ensuring that all components work in unison to reduce emissions and comply with environmental regulations. The clamp’s role in this assembly is to provide a stable and leak-free connection, which is fundamental for the system’s performance and longevity.

Conclusion

The 4965323 T Bolt Clamp is a key component in the effective operation and maintenance of engine systems, particularly within the aftertreatment device and its associated components. Its ability to provide secure and reliable connections is indispensable for the optimal functioning of the aftertreatment system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.