This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

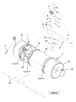

The Cummins 4965063 V Band Clamp is a component designed for use in commercial trucks, specifically within the exhaust and intake systems. Understanding its function and benefits contributes to maintaining the efficiency and reliability of truck operations.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to seal and connect components in exhaust and intake systems. They feature a V-shaped band that, when tightened, compresses a gasket between two flanges, creating a secure and leak-proof seal. This design allows for easy installation and removal without specialized tools, making them popular in various industrial applications 1.

Role of the 4965063 V Band Clamp in Truck Operation

In truck operation, the 4965063 V Band Clamp is positioned within the exhaust or intake system to maintain system integrity by ensuring a tight seal between connected components. This seal is vital for the efficient flow of exhaust gases or intake air, directly impacting the performance and emissions of the truck 2.

Key Features of the 4965063 V Band Clamp

The 4965063 V Band Clamp is constructed from high-quality materials, ensuring durability and resistance to harsh conditions found in commercial truck environments. Its design includes precision-engineered elements that facilitate easy installation and reliable sealing. Additionally, the clamp may feature unique characteristics such as corrosion-resistant coatings or enhanced gasket materials to further improve its functionality 3.

Benefits of Using the 4965063 V Band Clamp

Utilizing the 4965063 V Band Clamp offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks that can affect engine performance and emissions. The ease of installation saves time during maintenance and minimizes the potential for human error. Furthermore, its durability contributes to long-term cost savings by reducing the frequency of replacements. The clamp’s design also allows for quick removal and reinstallation, facilitating efficient maintenance procedures.

Installation Process

Installing the 4965063 V Band Clamp requires attention to detail to ensure a proper seal. Begin by aligning the flanges of the components to be connected. Place the V Band Clamp over the flanges, ensuring it is centered. Tighten the clamp using the appropriate tool, applying even pressure to achieve a uniform seal. It is important to follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the gasket, or under-tightening, which can lead to leaks.

Troubleshooting Common Issues

Common issues with V Band Clamps include leaks or improper sealing. These problems can often be traced back to incorrect installation, such as misalignment of flanges or improper torque application. To address these issues, first, ensure that the flanges are clean and free of debris. Recheck the alignment and reapply the clamp, making sure to follow the correct torque specifications. If leaks persist, inspect the gasket for damage and replace it if necessary.

Maintenance Tips

Regular maintenance of the 4965063 V Band Clamp is key to ensuring its longevity and optimal performance. Inspect the clamp and gasket at regular intervals for signs of wear or damage. Clean the flanges and clamp as needed to remove any buildup that could affect the seal. Following these maintenance practices will help prevent issues and ensure the clamp continues to function effectively.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. Their commitment to excellence is evident in the design and performance of components like the 4965063 V Band Clamp, underscoring their dedication to meeting the demanding needs of commercial truck applications.

Cummins V Band Clamp 4965063 Compatibility

The Cummins V Band Clamp part number 4965063 is a versatile component designed to fit seamlessly with a variety of Cummins engines. This clamp is essential for ensuring a secure seal in various applications, particularly in systems where a tight, leak-proof connection is critical.

ISC8.3 CM2250 Engines

The V Band Clamp 4965063 is compatible with the ISC8.3 CM2250 engines. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The clamp’s design allows it to fit snugly around the engine’s components, providing a dependable seal that prevents leaks and maintains system integrity.

Grouping of Engines

While the V Band Clamp 4965063 is specifically noted for its use with the ISC8.3 CM2250 engines, it is also compatible with other Cummins engines within the same family. This compatibility extends to engines that share similar design features and sealing requirements, ensuring that the clamp can be used across multiple models without modification.

The clamp’s universal design makes it an ideal choice for technicians and engineers working with Cummins engines, providing a reliable solution for maintaining the integrity of critical connections.

Role of Part 4965063 V Band Clamp in Engine Systems

The part 4965063 V Band Clamp is instrumental in ensuring the secure and efficient connection of various components within engine systems. Its application spans across several key areas, enhancing the overall performance and reliability of the engine.

Aftertreatment Device

In the context of an aftertreatment device, the V Band Clamp plays a significant role in maintaining the integrity of the exhaust system. It ensures that the connections between the exhaust pipes and the aftertreatment components, such as Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems, remain tight and leak-free. This is essential for the effective reduction of emissions and the overall efficiency of the aftertreatment process.

Aftertreatment System

Within the aftertreatment system, the V Band Clamp is used to connect various components, including sensors, dosing modules, and exhaust pipes. Its robust design allows for easy installation and removal, facilitating maintenance and repairs. The clamp ensures that all connections are secure, preventing any potential leaks that could compromise the system’s performance.

Air Shutdown Device

The air shutdown device relies on precise and secure connections to function correctly. The V Band Clamp is employed to connect the air shutdown device to the intake system, ensuring that the airflow can be effectively controlled. This is particularly important during engine shutdown procedures, where the device must seal off the air intake to prevent unauthorized engine starts.

Air Shutdown

In the broader air shutdown system, the V Band Clamp is used to connect various components that control the airflow to the engine. This includes connections to valves, actuators, and sensors. The secure fit provided by the clamp ensures that the air shutdown system operates smoothly, contributing to the engine’s overall safety and performance.

Fluid Doser

The fluid doser, which is part of the aftertreatment system, requires precise and reliable connections to deliver the necessary fluids (such as Diesel Exhaust Fluid - DEF) into the exhaust stream. The V Band Clamp is used to connect the fluid doser to the exhaust system and other related components. This ensures that the fluid is delivered accurately and efficiently, enhancing the effectiveness of the aftertreatment process.

Overall, the part 4965063 V Band Clamp is a versatile and essential component in various engine systems, providing secure and reliable connections that are vital for the efficient operation of aftertreatment devices, air shutdown systems, and fluid dosers.

Conclusion

The Cummins 4965063 V Band Clamp is a critical component in the maintenance and efficiency of commercial truck engines. Its design and features ensure secure and reliable connections within the exhaust and intake systems, contributing to the overall performance and emissions control of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.