This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

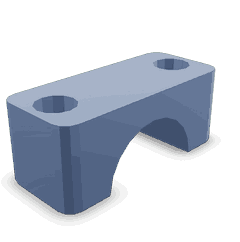

The Cummins 4959404 Tube Clamp is a specialized component designed for use in commercial truck maintenance and operation. This Cummins part plays a role in ensuring the secure connection of various tubing systems within a truck, contributing to the overall efficiency and reliability of the vehicle 1.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to secure and connect tubing systems in both automotive and industrial applications. They function by providing a tight, leak-proof seal around the tubing, which is important for maintaining the integrity of fluid and gas transport systems. Tube clamps come in various designs and materials, each suited to specific applications based on the type of tubing and the environmental conditions they will encounter 2.

Purpose of the Cummins 4959404 Tube Clamp

The Cummins 4959404 Tube Clamp is specifically designed to play a role in the secure connection of tubing systems within commercial trucks. It is applied in various truck systems and components, including fuel lines, hydraulic systems, and coolant circuits. By ensuring a reliable connection, this Cummins part helps maintain the performance and safety of these critical systems 3.

Key Features

The Cummins 4959404 Tube Clamp is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precision-engineered components that allow for a secure fit around the tubing, minimizing the risk of leaks. Additionally, it features easy-to-use installation mechanisms that facilitate quick and efficient assembly.

Benefits of Using the Cummins 4959404 Tube Clamp

Utilizing the Cummins 4959404 Tube Clamp offers several advantages. It contributes to improved system integrity by providing a secure and leak-proof connection. The ease of installation reduces downtime during maintenance procedures. Furthermore, its durable construction ensures long-term reliability, minimizing the need for frequent replacements.

Installation Process

Proper installation of the Cummins 4959404 Tube Clamp involves several steps to ensure a secure and effective connection. Begin by cleaning the tubing to remove any debris or contaminants. Position the clamp around the tubing, ensuring it is aligned correctly. Use the provided tools to tighten the clamp gradually, avoiding over-tightening which could damage the tubing. Verify the connection by checking for leaks and ensuring the clamp is securely fastened.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4959404 Tube Clamp is important to ensure continued performance and safety. Inspect the clamp periodically for signs of wear, corrosion, or damage. If any issues are detected, address them promptly to prevent system failures. Common troubleshooting steps include tightening loose clamps, replacing worn components, and ensuring the tubing remains free of obstructions.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 4959404 Tube Clamp, it is important to observe several safety guidelines. Ensure the truck is turned off and the system is depressurized before beginning any work. Use appropriate personal protective equipment (PPE) to safeguard against injuries. Follow all manufacturer recommendations and safety protocols to protect both personnel and the truck’s systems.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the commercial truck industry. Founded in 1919, the company has a diverse product range that includes engines, filtration systems, and aftermarket parts. Cummins is known for its commitment to quality and reliability, making its components, like the 4959404 Tube Clamp, a trusted choice for commercial truck applications 4.

Role of Part 4959404 Tube Clamp in Plumbing and Aftercooler Water Systems

The Tube Clamp, identified by part number 4959404, is an essential component in both plumbing and aftercooler water systems within engine setups.

In plumbing systems, the Tube Clamp ensures secure connections between various sections of tubing. This is particularly important in high-pressure environments where leaks can lead to system failures or inefficiencies. The clamp provides a reliable seal, accommodating slight misalignments and vibrations that are common in dynamic engine environments. It also simplifies the assembly and disassembly processes, allowing for easier maintenance and repairs.

In aftercooler water systems, the Tube Clamp plays a significant role in maintaining the integrity of the cooling circuit. Aftercoolers are used to reduce the temperature of compressed air in turbocharged engines, and the efficient circulation of cooling water is vital for optimal performance. The Tube Clamp ensures that connections in the water lines remain tight and leak-free, which is essential for consistent cooling and preventing overheating. This reliability is particularly important in high-stress applications where the aftercooler is subjected to rapid temperature changes and mechanical vibrations.

Overall, the Tube Clamp (part 4959404) contributes to the robustness and efficiency of both plumbing and aftercooler water systems by providing secure, durable connections that can withstand the demanding conditions of engine operation.

Conclusion

The Cummins 4959404 Tube Clamp is a vital component in the maintenance and operation of commercial trucks. Its role in securing tubing systems ensures the reliability and efficiency of critical truck systems. With its durable construction, ease of installation, and maintenance benefits, this Cummins part is a trusted solution for commercial truck applications.

-

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007.

↩ -

Gas Turbine Engineering Handbook, Second Edition, Meherwan P. Boyce, Gulf Professional Publishing, 2002.

↩ -

D4.0 CM2620 D103B, Bulletin Number 5579480, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.