This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

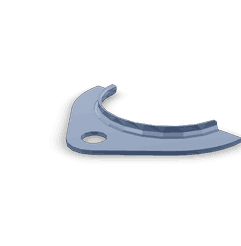

The Cummins 4006814 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s tubing systems, ensuring the secure and efficient operation of these systems. Understanding its purpose and significance is vital for maintaining the overall performance and safety of commercial trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place, ensuring a secure connection without the need for welding or soldering. They are widely used in automotive and industrial applications to join tubing systems, allowing for easy assembly, disassembly, and maintenance. Tube clamps come in various designs and materials, each suited to specific applications based on the type of tubing and the environment in which they will be used 1.

Purpose of the 4006814 Tube Clamp

The Cummins 4006814 Tube Clamp is designed to secure and maintain the integrity of tubing systems in commercial trucks. It plays a role in ensuring that the connections between tubing segments are tight and leak-free, which is crucial for the proper functioning of the truck’s systems. By providing a reliable connection, the clamp contributes to the overall efficiency and safety of the vehicle.

Key Features

The Cummins 4006814 Tube Clamp features a durable material composition, typically including high-strength steel or aluminum, which offers resistance to corrosion and wear. Its design includes elements such as a band clamp mechanism that allows for easy adjustment and a secure fit around the tubing. Additionally, the clamp may have unique attributes like a protective coating to enhance its performance and longevity in harsh operating conditions.

Benefits

Using the Cummins 4006814 Tube Clamp offers several benefits. It improves safety by ensuring secure connections that prevent leaks and failures in the tubing systems. The clamp also enhances reliability, as it is designed to withstand the rigors of commercial truck operation. Furthermore, it contributes to efficiency by allowing for quick and easy installation and maintenance, reducing downtime for the vehicle.

Installation Process

Installing the Cummins 4006814 Tube Clamp involves several steps. First, ensure the tubing is clean and free of debris. Next, position the clamp around the tubing where the connection is to be made. Use the appropriate tools to tighten the clamp until it achieves a secure fit. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the clamp is properly installed without over-tightening, which could damage the tubing.

Troubleshooting and Maintenance

Common issues with tube clamps include leaks due to improper installation or wear over time. To troubleshoot these problems, inspect the clamp for signs of damage or corrosion and ensure it is properly tightened. Regular maintenance involves checking the clamp for wear and replacing it if necessary to ensure the longevity and effectiveness of the tubing system.

Compatibility and Applications

The Cummins 4006814 Tube Clamp is designed to work with specific types of tubing and systems found in commercial trucks. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. The clamp is typically used in applications where secure, leak-free connections are required, such as in fuel, air, and hydraulic systems.

Safety Considerations

When installing or maintaining the Cummins 4006814 Tube Clamp, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the vehicle is properly supported, and following all manufacturer instructions for installation and maintenance. Additionally, be aware of the potential for high-pressure systems and take precautions to avoid injury from leaks or failures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses.

Tube Clamp 4006814 in Cummins Engines

The Tube Clamp 4006814 is a critical component in various Cummins engines, ensuring the integrity and functionality of the engine’s systems. This part is designed to secure and maintain the alignment of tubes, hoses, and other components, preventing leaks and ensuring optimal performance.

QSK78 Series

In the QSK78 series engines, the Tube Clamp 4006814 is utilized to secure coolant and fuel lines. Its robust design ensures that these lines remain tightly fastened under varying operational conditions, thereby preventing any potential leaks that could compromise engine performance.

CM500 Series

Similarly, in the CM500 series engines, the Tube Clamp 4006814 plays a pivotal role in securing various fluid lines. This includes coolant, oil, and other critical fluid lines that are essential for the engine’s operation. The clamp’s design allows for easy installation and removal, facilitating maintenance and repair processes.

Application Across Models

The Tube Clamp 4006814 is not limited to a single model but is a versatile component used across multiple Cummins engine models. Its design and functionality make it an essential part of the engine’s infrastructure, ensuring that all connected tubes and hoses are securely fastened and properly aligned. This helps maintain the overall efficiency and reliability of the engine.

By integrating the Tube Clamp 4006814 into their design, Cummins ensures that their engines can operate under various conditions without the risk of leaks or misalignments, which could lead to performance issues or failures.

Role of Part 4006814 Tube Clamp in Plumbing and Intercooler Water Systems

The 4006814 Tube Clamp is an essential component in both plumbing and intercooler water systems, ensuring secure and leak-free connections.

Plumbing Systems

In plumbing systems, the 4006814 Tube Clamp is utilized to connect various sections of tubing, whether they are made of metal, plastic, or rubber. It ensures that the joints remain tight under pressure, preventing leaks that could lead to water damage or system failure. The clamp is particularly useful in applications where vibrations or movement might otherwise loosen connections, such as in automotive or industrial plumbing setups.

Intercooler Water Systems

In intercooler water systems, the 4006814 Tube Clamp plays a significant role in maintaining the integrity of the cooling circuit. Intercoolers are used to reduce the temperature of compressed air from a turbocharger before it enters the engine’s combustion chamber. The Tube Clamp secures the hoses that carry coolant through the intercooler, ensuring that the flow remains consistent and unimpeded. This is vital for optimal engine performance and efficiency, as any restriction or leak in the coolant lines could lead to overheating and reduced engine power.

By providing a reliable connection in both plumbing and intercooler water systems, the 4006814 Tube Clamp contributes to the overall functionality and durability of these critical systems.

Conclusion

The Cummins 4006814 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and various Cummins engines. Its role in securing and maintaining the integrity of tubing systems ensures the safe, efficient, and reliable operation of these vehicles and engines. By understanding its features, benefits, and proper installation and maintenance procedures, users can ensure the longevity and effectiveness of their tubing systems.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.