This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

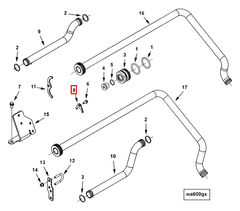

The 4006460 Tube Clamp, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that enhance the performance and reliability of trucks. This Cummins part is one such component, playing a significant role in the secure connection and maintenance of tubing systems within these vehicles.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure and connect tubing in various automotive and industrial applications. They function by compressing the tubing against a saddle or band, creating a tight seal that prevents leaks and ensures the integrity of the fluid or gas transport system. Tube clamps are favored for their ease of installation, adjustability, and the ability to provide a secure connection without the need for welding or soldering 1.

Purpose of the 4006460 Tube Clamp in Truck Operations

This part is specifically designed to play a role in the operation of commercial trucks by securing tubing in various systems. It is commonly used in fuel, air, and hydraulic systems where reliable connections are paramount. By providing a secure and leak-proof connection, the 4006460 Tube Clamp contributes to the efficient and safe operation of these systems.

Key Features

The 4006460 Tube Clamp features a design that includes a band made from durable materials, ensuring resistance to corrosion and wear. Its construction allows for easy adjustment, accommodating various tubing sizes and providing a snug fit. Additionally, the clamp’s design facilitates quick installation and removal, which is beneficial during maintenance procedures.

Benefits of Using the 4006460 Tube Clamp

Utilizing this part offers several advantages. It enhances the reliability of tubing connections, reducing the risk of leaks and system failures. The ease of installation means less downtime during maintenance, and its durable construction ensures long-term performance. Moreover, the clamp’s design allows for straightforward maintenance, contributing to the overall efficiency of truck operations.

Installation Process

To install the 4006460 Tube Clamp, first, ensure the tubing is clean and free of any obstructions. Position the clamp around the tubing and align it with the saddle. Using the appropriate tools, tighten the band until the tubing is securely held in place. It is important to achieve the correct tension to ensure a leak-proof connection without damaging the tubing.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or loose connections, can often be traced back to improper installation or wear and tear. To address these problems, inspect the clamp for signs of damage or corrosion. Ensure the band is tightened to the manufacturer’s specifications. If leaks persist, the tubing or clamp may need to be replaced.

Maintenance Tips

Regular maintenance of the 4006460 Tube Clamp involves periodic inspection for signs of wear, corrosion, or looseness. Cleaning the clamp and surrounding areas can prevent the buildup of debris that may affect performance. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help ensure the longevity and optimal performance of the clamp.

Safety Considerations

When installing or maintaining the 4006460 Tube Clamp, it is important to observe safety guidelines to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring the vehicle is securely parked, and following all manufacturer instructions for installation and maintenance. Additionally, be aware of the system pressure and any potential hazards associated with the fluids or gases being transported.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial vehicle industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for commercial vehicle operators worldwide.

Tube Clamp 4006460 in Cummins Engines

The 4006460 Tube Clamp is a critical component in several Cummins engine models, ensuring the integrity and functionality of the engine’s cooling system. This part is designed to securely hold and seal tubes, preventing leaks and maintaining the system’s efficiency.

QSK78 CM500 Engines

In the QSK78 CM500 engines, the 4006460 Tube Clamp plays a vital role in the cooling system. It is used to attach and seal various coolant tubes, ensuring that the engine operates at optimal temperatures. This clamp is engineered to withstand high pressures and temperatures, providing a reliable connection that is essential for the engine’s performance.

Grouping of Engines

The 4006460 Tube Clamp is compatible with a range of Cummins engines, including but not limited to the QSK78 CM500 series. Its design allows for versatility across different engine models, making it a standard component in many Cummins applications. This compatibility ensures that the clamp can be used across various engine configurations, providing a consistent and reliable solution for securing coolant tubes.

Role of Part 4006460 Tube Clamp in Engine Systems

The 4006460 Tube Clamp is an essential component in various engine systems, ensuring secure and reliable connections. In plumbing applications, this tube clamp is utilized to join pipes and hoses, maintaining the integrity of fluid pathways. It plays a significant role in the aftercooler water system by securing the connections between the aftercooler and the associated piping, which is vital for efficient cooling of compressed air.

In the broader system context, the tube clamp is employed in the auxiliary cooling system to connect radiator hoses and coolant lines. This ensures consistent coolant flow, which is necessary for maintaining optimal engine temperatures. Additionally, the tube clamp is used in the thermostat housing bracket assembly to secure the connections between the thermostat housing and the engine block or intake manifold. This application is important for regulating coolant flow based on engine temperature, contributing to overall engine efficiency and longevity.

The 4006460 Tube Clamp’s versatility and reliability make it a fundamental piece in ensuring the proper function and durability of these engine systems.

Conclusion

The 4006460 Tube Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its design and features contribute to the reliability and efficiency of various systems, including fuel, air, and hydraulic systems. Regular maintenance and proper installation are key to ensuring the longevity and performance of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 4006460 Tube Clamp, making it a trusted component in the commercial vehicle industry.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.