This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

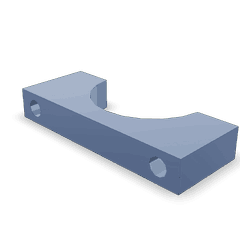

The Tube Clamp 4000952 by Cummins is a component designed for use in commercial trucks. It serves a primary function in securing tubing systems, which is vital for maintaining the integrity of various truck systems. This clamp ensures that connections remain secure under operational conditions, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure tubing in automotive and industrial applications. They operate by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the tubing remains in place. Tube clamps are commonly used in systems where flexibility and ease of installation are required, such as in fuel lines, brake systems, and hydraulic applications .

Purpose of Tube Clamp 4000952 in Truck Operations

Tube Clamp 4000952 plays a specific role in the operation of commercial trucks by securing tubing in various systems. Its application can be found in fuel lines, hydraulic systems, and other critical areas where secure and leak-free connections are necessary. By maintaining these connections, the clamp contributes to the efficient and safe operation of the truck .

Key Features of Tube Clamp 4000952

The design and construction of Tube Clamp 4000952 include several features that enhance its performance. It is composed of durable materials that can withstand the rigors of commercial truck environments. The clamping mechanism is designed to provide a secure fit without damaging the tubing, ensuring long-term reliability. Additionally, any unique attributes such as corrosion resistance or ease of adjustment are incorporated to improve functionality .

Benefits of Using Tube Clamp 4000952

Utilizing Tube Clamp 4000952 offers several advantages. Its durability ensures long-lasting performance, reducing the need for frequent replacements. The ease of installation allows for quick setup and adjustment, minimizing downtime. Reliability in securing tubing connections ensures that systems operate without leaks, contributing to the overall safety and efficiency of the truck.

Installation Guidelines

Proper installation of Tube Clamp 4000952 involves several steps to ensure a secure fit. Begin by preparing the tubing, ensuring it is clean and free of any debris. Position the clamp around the tubing and tighten it according to the manufacturer’s specifications. Verify that the clamp is securely fastened and that there are no gaps or leaks in the connection.

Maintenance and Troubleshooting

Regular maintenance of Tube Clamp 4000952 involves inspecting the clamp for signs of wear or damage. Common issues such as leaks or loose connections can often be addressed by re-tightening the clamp or replacing it if necessary. Ensuring that the tubing and clamp remain in good condition will help prevent operational disruptions.

Compatibility and Applications

Tube Clamp 4000952 is typically used in various commercial truck systems, including fuel lines and hydraulic systems. It is important to consider compatibility with specific tubing types and sizes to ensure optimal performance. Understanding the applications for which this clamp is designed will help in selecting the appropriate component for your truck’s needs.

Safety Considerations

When installing or maintaining Tube Clamp 4000952, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment and ensuring that the truck is safely supported during maintenance activities. Following these precautions helps to protect both the operator and the vehicle’s systems.

Cummins Corporation Overview

Cummins Corporation is a well-established entity in the commercial truck industry, known for its comprehensive product range and commitment to quality. With a history of innovation and excellence, Cummins provides solutions that enhance the performance and reliability of commercial vehicles. Their products, including Tube Clamp 4000952, are designed with a focus on durability and efficiency.

Role of Part 4000952 Tube Clamp in Engine Systems

The 4000952 Tube Clamp is an essential component in securing and maintaining the integrity of various hoses and tubes within engine systems. Specifically, it plays a significant role in the breather and crankcase systems, ensuring efficient operation and reliability.

In the breather system, the 4000952 Tube Clamp is used to secure the breather hoses. These hoses are responsible for allowing air to escape from the crankcase, which helps maintain proper pressure levels. The clamp ensures a tight and leak-free connection, preventing air leaks that could lead to inefficient engine performance.

Within the crankcase breather kit, the Tube Clamp is employed to connect the breather hose to the crankcase and other components such as the air intake system. This connection is vital for venting crankcase vapors and contaminants, which if not properly managed, could lead to oil contamination and reduced engine lifespan.

Overall, the 4000952 Tube Clamp contributes to the seamless functioning of these systems by providing a secure and durable connection point for critical hoses and tubes.

Conclusion

The Tube Clamp 4000952 by Cummins is a critical component in the maintenance and operation of commercial trucks. Its role in securing tubing systems ensures the reliability and efficiency of various truck systems. With its durable construction and ease of installation, this part is essential for maintaining secure and leak-free connections in fuel lines, hydraulic systems, and other critical areas. Regular maintenance and proper installation are key to maximizing the benefits of using this clamp, ensuring the long-term performance and safety of commercial vehicles.

: Han, Z. (2022). *Simulation and Optimization of Internal Combustion Engines*. SAE International.

: Sobey, E. (2009). *A Field Guide to Automotive Technology*. Chicago Review Press.

: Mananathan, R. (2022). *Automobile Wheel Alignment and Wheel Balancing*. SAE International.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.