This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

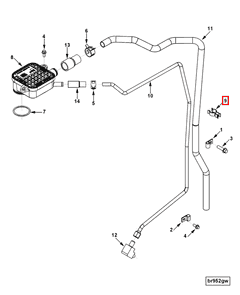

The 3972653 Tube Clamp, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of trucks. This part is significant in this context as it plays a role in securing and connecting various tubing systems within commercial trucks, ensuring the integrity and functionality of these systems.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing in automotive and industrial applications. They function by providing a tight seal around the tubing, which helps in maintaining the pressure and flow of fluids or gases within the system. Tube clamps are preferred in many applications due to their ease of installation, adjustability, and the secure connection they provide. They are commonly used in fuel lines, brake systems, and other fluid transport systems where reliable connections are necessary 1.

Purpose of the 3972653 Tube Clamp in Truck Operations

This Cummins part is specifically designed to play a role in the operation of commercial trucks by securing and connecting tubing systems. It is applied in various truck systems where fluid or gas transport is required, such as in the fuel delivery system, brake lines, and other hydraulic or pneumatic systems. The clamp ensures that these systems operate under the correct pressure and without leaks, which is vital for the safe and efficient operation of the truck.

Key Features of the 3972653 Tube Clamp

This part is constructed with features that enhance its performance and durability. It is made from materials that are resistant to corrosion and wear, ensuring longevity in demanding truck environments. The clamping mechanism is designed to provide a secure and adjustable fit around the tubing, allowing for precise control over the connection. Additionally, the clamp may include unique attributes such as a protective coating or a design that facilitates easy installation and removal.

Benefits of Using the 3972653 Tube Clamp

Using this part offers several advantages. It contributes to improved safety by ensuring secure connections in critical systems. The ease of installation reduces downtime during maintenance or repairs. Its reliable performance minimizes the risk of leaks or failures, and the clamp’s design may offer maintenance benefits, such as easier access for inspection or replacement.

Installation Process

Installing the 3972653 Tube Clamp involves several steps to ensure a secure and effective connection. The process typically requires specific tools, such as a torque wrench, to achieve the correct clamping force. Best practices include cleaning the tubing before installation, ensuring the clamp is properly aligned, and tightening the clamp to the manufacturer’s specified torque. Following these steps helps to ensure the clamp functions as intended.

Troubleshooting Common Issues

Common problems with tube clamps, such as leaks or improper clamping, can often be traced to installation errors or wear and tear. To address these issues, it is important to inspect the clamp and tubing for damage, ensure the clamp is correctly installed, and replace any worn components. Regular maintenance checks can help identify potential problems before they lead to system failures.

Maintenance Tips

To ensure the long-term performance of the 3972653 Tube Clamp, regular maintenance checks are recommended. This includes inspecting the clamp for signs of wear, corrosion, or damage, and ensuring that all connections are secure. Cleaning the clamp and tubing, and lubricating moving parts if applicable, can also contribute to the clamp’s durability and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all of which are designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its products, including the 3972653 Tube Clamp, deliver reliable performance in the field 2.

Compatibility with Cummins Engines

This part is designed to fit seamlessly within a variety of Cummins engine models. It is crucial for maintaining the integrity of the engine’s tubing systems, ensuring that connections remain secure and leak-free.

QSC8.3 CM850 (CM2850)

This part is specifically engineered to fit the QSC8.3 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The clamp ensures that the tubing systems within this engine remain tightly secured, preventing any potential leaks that could compromise engine performance.

Grouping of Engines

While this part is explicitly designed for the QSC8.3 CM850 (CM2850), it is also compatible with other Cummins engines within the same family or those with similar tubing configurations. This compatibility extends to various models that share design and engineering principles with the QSC8.3 CM850 (CM2850).

By ensuring that the Tube Clamp fits these engines, Cummins maintains a high standard of quality and reliability across its engine lineup. This part is integral to the overall functionality and longevity of the engine, providing a secure connection for critical tubing systems.

Role of Part 3972653 Tube Clamp in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine systems, particularly in the breather and crankcase components.

Breather System Integration

In the breather system, the Tube Clamp secures the hoses that connect the breather to the engine block and other components. This ensures that the breather system can effectively vent excess pressure and moisture from the crankcase, maintaining optimal engine performance and longevity. The secure fit provided by the Tube Clamp prevents leaks and ensures that the breather system operates within specified parameters, contributing to consistent engine operation.

Crankcase Ventilation

The crankcase ventilation system relies on the Tube Clamp to maintain a sealed connection between the crankcase and the ventilation hoses. This is essential for managing the buildup of gases and moisture within the crankcase, which if left unchecked, can lead to increased wear on engine components and reduced efficiency. The Tube Clamp ensures that the ventilation system can effectively route these byproducts away from the crankcase, thereby preserving the engine’s internal environment and enhancing its reliability.

Overall System Efficiency

By ensuring secure and leak-free connections in both the breather and crankcase systems, the Tube Clamp plays a significant role in the overall efficiency of the engine. It helps in maintaining the designed pressure and flow rates within these systems, which are vital for the engine’s performance and durability. The reliable performance of the Tube Clamp contributes to the engine’s ability to operate smoothly under various conditions, reducing the likelihood of unexpected failures and extending the maintenance intervals 3.

Conclusion

The 3972653 Tube Clamp by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its role in securing and connecting tubing systems ensures the integrity and functionality of these systems, contributing to the overall efficiency and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring long-term performance and safety in commercial truck operations.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.