This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

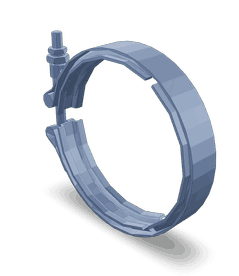

The V Band Clamp 3968666, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty vehicles. This Cummins part is integral to the exhaust and intake systems of these trucks, ensuring secure and efficient connections.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to connect pipes and other tubular components. They consist of a band that wraps around the tubing and a bolt that tightens the band, creating a secure seal. These clamps are widely used in industrial and automotive applications due to their ease of installation, reliability, and ability to provide a leak-free connection. They are particularly valued in high-vibration environments where traditional clamping methods may fail 1.

Purpose of the V Band Clamp 3968666 in Truck Operations

In the operation of a truck, the V Band Clamp 3968666 plays a significant role by securing connections in the exhaust and intake systems. Its design allows for quick and easy installation, which is beneficial during maintenance and repair operations. The clamp ensures that the connections remain intact under the dynamic conditions experienced by commercial trucks, thereby maintaining system integrity and efficiency.

Key Features of the V Band Clamp 3968666

The V Band Clamp 3968666 is characterized by several key features that enhance its performance. It is constructed from high-quality materials that offer durability and resistance to corrosion. The design of the clamp allows for a uniform distribution of clamping force, which ensures a secure and leak-free connection. Additionally, the clamp is engineered to accommodate minor misalignments between connected components, further enhancing its reliability in demanding applications.

Benefits of Using the V Band Clamp 3968666

The use of the V Band Clamp 3968666 offers several advantages. Its design facilitates ease of installation, reducing downtime during maintenance operations. The clamp’s durability ensures long-term reliability, minimizing the need for frequent replacements. Furthermore, the efficient sealing provided by the V Band Clamp 3968666 contributes to the overall performance and efficiency of the truck’s exhaust and intake systems.

Installation Process

Installing the V Band Clamp 3968666 involves several steps to ensure a secure and effective connection. First, the tubular components to be joined should be aligned and positioned correctly. The V Band is then wrapped around the tubing, and the bolt is tightened to the specified torque using a torque wrench. It is important to follow the manufacturer’s guidelines to avoid over-tightening, which can damage the components, or under-tightening, which can lead to leaks.

Troubleshooting Common Issues

Common issues with V Band Clamps may include leaks, difficulty in installation, or clamp failure. Leaks can often be traced to improper installation or torque settings. Ensuring that the components are correctly aligned and that the clamp is tightened to the manufacturer’s specifications can resolve these issues. Difficulty in installation may be due to misalignment of the components, which can be addressed by adjusting the position of the tubing before applying the clamp. Clamp failure is rare but can occur due to material fatigue or corrosion; regular inspection and maintenance can help identify and address these issues before they lead to failure.

Maintenance Tips

Regular maintenance of the V Band Clamp 3968666 is key to ensuring its longevity and reliable performance. This includes periodic inspection for signs of wear, corrosion, or damage. The clamp should be re-torqued according to the manufacturer’s recommendations to maintain the integrity of the seal. Additionally, keeping the area around the clamp clean and free of debris can prevent contamination that might compromise the seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among commercial truck operators and manufacturers.

V Band Clamp (Part 3968666) in Cummins Engines

The V Band Clamp, identified by the part number 3968666, is a crucial component in various Cummins engines, including the ISC CM554, ISL CM554, QSC8.3 CM554, and QSL9 CM554. This part plays a pivotal role in ensuring the integrity and functionality of these engines by providing a secure seal where different parts of the engine meet.

Application in ISC CM554 and ISL CM554 Engines

In the ISC CM554 and ISL CM554 engines, the V Band Clamp is typically used in areas where a tight, leak-proof seal is essential. These engines are known for their reliability and efficiency, often used in heavy-duty applications such as trucks and construction equipment. The V Band Clamp helps maintain the pressure and prevent leaks in critical areas, ensuring the engine operates smoothly and efficiently.

Application in QSC8.3 CM554 and QSL9 CM554 Engines

Similarly, in the QSC8.3 CM554 and QSL9 CM554 engines, the V Band Clamp is employed to secure various components, ensuring that there are no gaps or leaks. These engines are often used in industrial and marine applications, where reliability and durability are paramount. The V Band Clamp’s ability to create a tight seal is essential in these environments, where exposure to harsh conditions is common.

Grouping by Application

While the V Band Clamp is used across different engine models, its application can be grouped based on the type of engine and the specific demands of the application. For instance:

-

Heavy-Duty Engines (ISC CM554, ISL CM554): These engines require robust sealing solutions to handle the rigors of heavy-duty operations. The V Band Clamp provides the necessary durability and sealing capability.

-

Industrial and Marine Engines (QSC8.3 CM554, QSL9 CM554): These engines operate in demanding environments, necessitating reliable sealing to prevent leaks and maintain performance. The V Band Clamp is designed to meet these stringent requirements.

By understanding the specific needs of each engine model and application, the V Band Clamp ensures that the engines perform optimally, maintaining their reliability and efficiency over time.

Role of Part 3968666 V Band Clamp in Engine Systems

The Part 3968666 V Band Clamp is an essential component in ensuring secure and efficient connections within engine systems. Specifically, it plays a significant role in the following areas:

Connection Integrity

In engine systems, the V Band Clamp is utilized to create robust and leak-free connections between various components. It ensures that all joints, whether they are between pipes, manifolds, or other exhaust system parts, remain tightly sealed. This is particularly important in high-stress environments where vibrations and thermal expansion can loosen connections over time. The clamp’s design allows for easy installation and removal while maintaining a strong grip, which is vital for the longevity and reliability of the engine system.

Exhaust Outlet Sealing

At the exhaust outlet, the V Band Clamp is instrumental in sealing the connection between the exhaust manifold and the exhaust pipe. This seal is necessary to prevent exhaust gases from escaping, which can lead to decreased engine performance and increased emissions. The clamp’s ability to withstand high temperatures and pressures makes it ideal for this application, ensuring that the exhaust system operates efficiently and safely. Additionally, the clamp helps in reducing the noise produced by the exhaust system, contributing to a quieter and more pleasant driving experience.

Conclusion

The V Band Clamp 3968666 is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure, leak-free connections in exhaust and intake systems, contributing to the overall performance and reliability of these heavy-duty vehicles. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.