This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

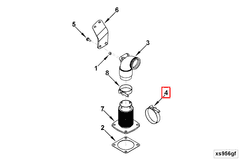

The T Bolt Clamp 3817008, manufactured by Cummins, is a critical component in commercial truck maintenance and operation. Cummins, a renowned name in the commercial vehicle industry, produces a range of parts and systems that enhance the efficiency and reliability of heavy-duty trucks. This part plays a significant role in maintaining the integrity of truck systems by securely fastening various components.

Basic Concepts of T Bolt Clamps

T Bolt Clamps are mechanical fasteners designed to secure components in various systems. They feature a T-shaped bolt that threads into a corresponding T-slot, providing a secure grip on the components they are intended to hold together. These clamps are widely used in mechanical systems for their simplicity, effectiveness, and ease of installation. They function by applying pressure to the components, ensuring they remain firmly in place despite vibrations and other dynamic forces encountered during operation 1.

Role of the 3817008 T Bolt Clamp in Truck Operation

The 3817008 T Bolt Clamp is specifically designed for use in commercial trucks. It secures components within the truck’s systems, ensuring that parts remain in place and function correctly. This clamp is applied in areas where secure fastening is required to maintain system integrity, such as in exhaust systems, fuel lines, and other critical components. Its application helps reduce the risk of component failure due to loosening, which can lead to operational issues or safety concerns 2.

Key Features of the 3817008 T Bolt Clamp

The 3817008 T Bolt Clamp is characterized by its robust design and material quality. It is made from materials that offer durability and resistance to corrosion, ensuring long-term performance in the demanding environment of commercial truck operation. The clamp’s design allows for easy installation, reducing downtime during maintenance procedures. It is compatible with a variety of truck models, making it a versatile choice for fleet maintenance.

Benefits of Using the 3817008 T Bolt Clamp

Utilizing the 3817008 T Bolt Clamp provides several advantages. It enhances the security of connections within the truck’s systems, offering resistance to vibration and dynamic forces that could otherwise loosen components over time. The clamp’s design and material contribute to its long-term reliability, reducing the need for frequent replacements and maintenance. This results in cost savings and improved operational efficiency for fleet managers 3.

Installation and Usage Guidelines

Proper installation of the 3817008 T Bolt Clamp involves several steps to ensure optimal performance. Begin by identifying the components that require securing. Use the appropriate tools to thread the T-shaped bolt into the T-slot, applying even pressure to ensure a secure fit. It is important to follow manufacturer guidelines for torque settings to avoid over-tightening, which can damage components, or under-tightening, which may not provide sufficient security. Regular checks should be performed to ensure the clamp remains securely fastened.

Troubleshooting Common Issues

Common issues with T Bolt Clamps include loosening due to vibration or corrosion over time. To address these problems, regular inspections should be conducted to identify any signs of wear or loosening. If a clamp is found to be loose, it should be re-tightened according to the manufacturer’s specifications. In cases of corrosion, the affected area should be cleaned, and the clamp may need to be replaced if damage is significant. Implementing a maintenance schedule can help prevent these issues from arising.

Maintenance Tips

To prolong the lifespan of the 3817008 T Bolt Clamp and ensure continued effective operation, regular maintenance checks are recommended. Inspect the clamp for signs of wear, corrosion, or loosening at regular intervals. Cleaning the clamp and its surrounding area can prevent the buildup of debris that may contribute to corrosion. Following these maintenance practices can help maintain the integrity of the truck’s systems and ensure safe, reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for fleet operators and maintenance professionals worldwide.

Cummins T Bolt Clamp 3817008 Compatibility

The Cummins T Bolt Clamp part number 3817008 is designed to fit seamlessly with various engine models, ensuring a secure and reliable connection. This part is integral in maintaining the structural integrity of the engine by securing bolts and preventing loosening over time.

Engine Compatibility

-

6B5.9 Series

- The T Bolt Clamp 3817008 is specifically engineered to integrate with the 6B5.9 engine series. Its robust design ensures that it can withstand the operational stresses and vibrations inherent in these engines, providing a dependable fastening solution.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, this part is also compatible with a range of other Cummins engines. Its universal design allows it to be used across multiple engine models, making it a versatile component in engine maintenance and repair.

Role of Part 3817008 T Bolt Clamp in Engine Systems

The T Bolt Clamp, identified by part number 3817008, is a critical component in the assembly and maintenance of various engine systems. Its primary function is to secure and maintain the integrity of connections within these systems.

Connection

In engine systems, the T Bolt Clamp is utilized to create robust and reliable connections between different components. It ensures that pipes, hoses, and other elements are firmly attached, minimizing the risk of leaks and disconnections. This is particularly important in high-pressure and high-temperature environments where secure connections are paramount.

Exhaust Outlet

When it comes to the exhaust outlet, the T Bolt Clamp plays a significant role in attaching the exhaust pipe to the engine block or manifold. This connection must be tight to prevent exhaust gases from escaping, which could lead to performance issues and increased emissions. The clamp’s design allows for easy installation and removal, facilitating maintenance and repairs.

Exhaust Kit

In the context of an exhaust kit, the T Bolt Clamp is often used to join various sections of the exhaust system. Whether connecting the downpipe to the catalytic converter or linking the muffler to the tailpipe, the clamp ensures a snug fit. This is vital for the efficient flow of exhaust gases and the overall performance of the exhaust system.

Exhaust Outlet Kit

For exhaust outlet kits, which may include multiple components such as headers, downpipes, and catalytic converters, the T Bolt Clamp is indispensable. It provides the necessary tension to hold these components in place, ensuring that the exhaust system operates as designed. This is especially important in aftermarket exhaust systems where custom fittings may be required.

Conclusion

Overall, the T Bolt Clamp (part 3817008) is a versatile and reliable component that enhances the functionality and durability of engine systems by securing critical connections. Its robust design, ease of installation, and compatibility with various engine models make it an essential part in the maintenance and operation of commercial trucks.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Arora, S., Abkenar, A.T., & Jayasi, S.G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.