This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

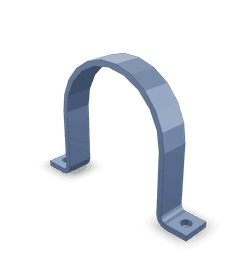

The Cummins 3814310 Tube Clamp is a component designed for securing and connecting tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems, contributing to overall vehicle performance and reliability.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold and connect tubing in automotive and industrial applications. They function by providing a secure grip around the tubing, ensuring that connections remain tight and leak-free. This is crucial for systems where fluid or gas transfer is necessary, such as fuel lines, hydraulic systems, and cooling systems 1.

Purpose of the 3814310 Tube Clamp in Truck Operation

The 3814310 Tube Clamp is utilized in commercial trucks to secure tubing in various systems. It plays a role in maintaining the structural integrity of these systems, ensuring that connections remain secure under operational conditions. Its application spans across different truck systems, including fuel delivery, hydraulic lines, and cooling systems, where reliable connections are paramount 2.

Key Features of the 3814310 Tube Clamp

The design and construction of the 3814310 Tube Clamp incorporate features that enhance its performance and durability. It is made from materials that offer resistance to corrosion and wear, ensuring longevity in demanding environments. The clamping mechanism is designed to provide a strong and consistent grip on the tubing, minimizing the risk of leaks or disconnections.

Benefits of Using the 3814310 Tube Clamp

Utilizing the 3814310 Tube Clamp offers several advantages. It contributes to improved system reliability by ensuring secure connections. The design of the clamp facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durability and resistance to environmental factors contribute to maintenance efficiency, as it requires less frequent replacement or adjustment.

Installation Process

Installing the 3814310 Tube Clamp involves several steps to ensure proper fitting and function. The process begins with preparing the tubing by cleaning and, if necessary, cutting it to the required length. The clamp is then positioned around the tubing and secured using the provided mechanism. Tools required for installation may include wrenches for tightening and possibly a tubing cutter for preparation.

Maintenance and Troubleshooting

Regular maintenance of the 3814310 Tube Clamp involves inspecting the clamp and tubing for signs of wear, corrosion, or leaks. Cleaning the clamp and ensuring that the clamping mechanism operates smoothly are also important practices. In the event of issues such as leaks or loose connections, troubleshooting may involve tightening the clamp, replacing damaged tubing, or, in some cases, replacing the clamp itself.

Compatibility and Applications

The 3814310 Tube Clamp is designed for use in a variety of commercial trucks and specific systems within these vehicles. Its versatility allows it to be applied in different contexts, from fuel systems to hydraulic lines, demonstrating its widespread application in the truck industry.

Safety Considerations

When installing, maintaining, or troubleshooting the 3814310 Tube Clamp, it is important to observe safety guidelines. This includes ensuring that the truck is properly shut down and, if applicable, that systems are depressurized before beginning work. Personal protective equipment should be worn to protect against potential hazards.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins products are known for their reliability and performance in the commercial truck industry. The 3814310 Tube Clamp is part of Cummins’ extensive product range, reflecting the company’s dedication to providing high-quality components for commercial vehicles.

Tube Clamp 3814310 in Cummins Engines

The Tube Clamp 3814310, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to secure and stabilize tubes, ensuring that they remain in place and do not shift during operation. Its application is vital for maintaining the integrity of the engine’s cooling and fuel systems.

Engine Models

- 6B5.9: The Tube Clamp 3814310 is used in the 6B5.9 engine to secure coolant and fuel lines. Its precise fit and robust construction ensure that these lines are held firmly, preventing leaks and maintaining optimal engine performance.

The Tube Clamp 3814310 is engineered to withstand the high pressures and temperatures typical of engine environments, making it a reliable choice for securing critical components in Cummins engines.

Role of Part 3814310 Tube Clamp in Engine Systems

Air Cleaner Mounting

The Tube Clamp 3814310 is instrumental in securing the air cleaner to its mounting bracket. This ensures a stable connection, preventing any undue movement that could lead to air leaks. A secure air cleaner is essential for maintaining the efficiency of the air filtration system, ensuring that the engine receives clean air for optimal combustion.

Air Intake Mounting

In the air intake system, the Tube Clamp 3814310 plays a significant role by firmly attaching the intake hose to the throttle body or intake manifold. This secure attachment is vital for maintaining the integrity of the air pathway, ensuring smooth airflow into the engine. Consistent airflow is necessary for stable engine performance and efficient fuel combustion.

Radiator Plumbing

For radiator plumbing, the Tube Clamp 3814310 is used to connect hoses to the radiator and other cooling system components. This ensures that the coolant flow remains uninterrupted, which is essential for effective heat dissipation from the engine. A reliable connection here prevents leaks and maintains the cooling system’s efficiency, contributing to the overall longevity and performance of the engine.

Conclusion

The Cummins 3814310 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features contribute to the reliability and efficiency of various truck systems, ensuring secure connections and reducing maintenance needs. Proper installation, maintenance, and understanding of its applications are key to leveraging the full benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.