This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

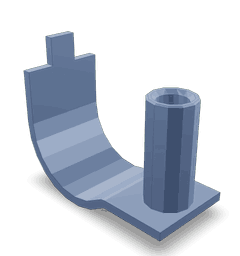

The Cummins 3649323 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by providing a tight, reliable seal that prevents leaks and ensures the integrity of fluid or gas flow within the system. Tube clamps come in various designs and materials, tailored to specific applications and environmental conditions 1.

Purpose of the Cummins 3649323 Tube Clamp

This Cummins part plays a role in securing and connecting tubing within a truck’s systems. It is applied in various components and systems where tubing integrity is paramount. This includes fuel lines, coolant systems, and other fluid transport mechanisms within the truck. By ensuring a secure connection, the clamp contributes to the system’s overall reliability and performance.

Key Features

The Cummins 3649323 Tube Clamp is characterized by several primary features that enhance its functionality and durability. These include its material composition, which is designed to withstand the environmental and operational stresses encountered in commercial truck applications. The design elements of the clamp, such as its band and screw mechanism, allow for easy adjustment and a secure fit around the tubing. Additionally, any unique attributes, such as corrosion resistance or ease of installation, further contribute to its effectiveness.

Benefits

Utilizing the Cummins 3649323 Tube Clamp offers several advantages. It contributes to improved system integrity by providing a secure and leak-proof connection. The ease of installation allows for quick and efficient setup, reducing downtime during maintenance procedures. Furthermore, its design facilitates maintenance efficiency, enabling straightforward access for inspection and replacement when necessary.

Installation Process

Installing the Cummins 3649323 Tube Clamp involves several steps to ensure a proper and secure fit. Begin by cleaning the tubing to remove any debris or contaminants that could affect the seal. Position the clamp around the tubing, ensuring it is aligned correctly. Tighten the screw mechanism gradually to achieve a snug fit without over-tightening, which could damage the tubing. Verify the connection’s integrity by checking for leaks or looseness.

Troubleshooting and Maintenance

Identifying and resolving common issues with the Cummins 3649323 Tube Clamp can extend its lifespan and maintain system performance. Regular inspections for signs of wear, corrosion, or leaks are recommended. If a leak is detected, the clamp may need adjustment or replacement. Routine maintenance, such as cleaning and lubricating moving parts, can prevent issues and ensure optimal performance.

Compatibility and Applications

The Cummins 3649323 Tube Clamp is designed for use in specific commercial truck systems and components. Its applications include, but are not limited to, fuel lines, coolant systems, and other fluid transport mechanisms. Ensuring compatibility with the truck’s make and model is crucial for proper function and safety.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3649323 Tube Clamp, observing safety guidelines and precautions is important. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and the engine is off during installation or maintenance procedures. Additionally, following manufacturer recommendations for torque settings and maintenance intervals can prevent accidents and ensure user safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the commercial truck industry. The 3649323 Tube Clamp, as part of Cummins’ product range, reflects the company’s commitment to quality and durability in automotive components.

Understanding the Role of Part 3649323 Tube Clamp in Engine Systems

In the intricate network of an engine system, the part 3649323 Tube Clamp serves a significant function by ensuring the secure and efficient connection of various components. This component is instrumental in maintaining the integrity and performance of the engine by facilitating the proper arrangement and function of critical systems.

Integration with Crankcase Breather System

The Tube Clamp is essential in the arrangement of the crankcase breather system. This system is designed to release pressure that builds up within the crankcase as a result of blow-by gases escaping past the piston rings. The Tube Clamp ensures that the breather tubes are firmly attached, preventing leaks and ensuring that the gases are effectively vented. This not only maintains optimal pressure levels within the crankcase but also contributes to the overall efficiency and longevity of the engine 2.

Role in CRC Breather Arrangement

In engines equipped with a Crankcase Ventilation (CRC) breather system, the Tube Clamp plays a vital role in the arrangement of the CRC breather tubes. These tubes are responsible for directing the crankcase vapors back into the intake system, where they can be re-burned. The secure attachment provided by the Tube Clamp is essential for the proper function of this system, ensuring that vapors are efficiently managed and do not contribute to environmental pollution or engine performance issues.

Ensuring Secure Connections

Beyond its specific applications in breather systems, the Tube Clamp is universally important for ensuring secure connections throughout the engine. Whether connecting hoses, tubes, or other components, the Tube Clamp provides a reliable method for maintaining these connections under the varying conditions and stresses of engine operation. This reliability is key to the consistent performance and durability of the engine system.

Conclusion

The Cummins 3649323 Tube Clamp is a fundamental component in the arrangement and function of engine systems, particularly in breather systems. Its role in securing connections and ensuring the efficient operation of these systems underscores its importance in the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.