3630804

Wire Tie Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Wire Tie Holder Clamp 3630804, manufactured by Cummins, is a component designed for the maintenance and operation of commercial trucks. This clamp provides a reliable solution for managing and securing wires within the vehicle’s electrical system.

Basic Concepts and Functionality

A Wire Tie Holder Clamp is designed to organize and secure wires, preventing them from moving freely within the truck’s electrical system. This clamp functions by holding wires in place, which helps maintain the integrity of the electrical connections and reduces the risk of damage from vibrations or other movements. The design principles behind the clamp focus on durability, ease of use, and effective wire management 1.

Purpose of the 3630804 Wire Tie Holder Clamp

The 3630804 Wire Tie Holder Clamp plays a role in the operation of a truck by organizing and securing wires. This organization helps prevent damage to the wires and ensures efficient electrical performance. By keeping wires in place, the clamp contributes to the overall reliability and safety of the truck’s electrical system 2.

Key Features

The 3630804 Wire Tie Holder Clamp features a robust material composition that enhances its durability. Its design includes elements that make it easy to install and remove, ensuring convenience during maintenance procedures. Additionally, the clamp may have unique attributes such as a specific shape or size that allows it to accommodate various wire diameters, setting it apart from other clamps.

Benefits

Using the 3630804 Wire Tie Holder Clamp offers several advantages. It improves wire management by keeping wires organized and secured, which reduces the risk of electrical faults. This, in turn, enhances the safety and reliability of the truck’s electrical system, contributing to overall vehicle performance and longevity 3.

Installation Process

To install the 3630804 Wire Tie Holder Clamp, gather the necessary tools, which may include a screwdriver and pliers. Begin by identifying the location where the clamp will be installed. Prepare the area by ensuring the wires are clean and dry. Place the clamp around the wires and secure it in place, following the manufacturer’s instructions for the best clamping effect. Ensure the clamp is tight enough to hold the wires securely without damaging them.

Troubleshooting and Maintenance

Common issues with wire tie holder clamps may include loosening over time or damage from environmental factors. To diagnose problems, inspect the clamp regularly for signs of wear or damage. Maintenance tips include cleaning the clamp and wires periodically and tightening the clamp if it becomes loose. These practices help prolong the lifespan and effectiveness of the clamp.

Safety Considerations

When installing, maintaining, or troubleshooting the 3630804 Wire Tie Holder Clamp, it is important to observe safety guidelines. Ensure the truck’s electrical system is turned off before beginning any work to prevent electrical shocks. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself during the process. Following these precautions helps ensure the safety of personnel and the integrity of the truck’s electrical system.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance truck components, Cummins has established a strong reputation for its product range, which includes engines, filtration systems, and aftermarket parts. The company’s dedication to excellence is reflected in its components, such as the 3630804 Wire Tie Holder Clamp, which are designed to meet the demanding requirements of commercial truck operations.

Compatibility with Cummins Engines

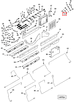

The Wire Tie Holder Clamp 3630804 is designed to secure and organize wiring harnesses and other electrical components in various Cummins engine systems. This clamp is engineered to provide a reliable and efficient method for managing wire ties, ensuring that they remain in place and do not interfere with engine operations.

ISB (Chrysler) Engines

In the ISB engines, the Wire Tie Holder Clamp 3630804 is strategically placed to manage the complex wiring systems that are integral to the engine’s operation. This clamp helps in maintaining the integrity of the electrical connections, ensuring that the wiring does not become a hazard during engine maintenance or operation.

K38 and K50 Engines

For the K38 and K50 engines, the Wire Tie Holder Clamp 3630804 plays a role in organizing the wiring harnesses that run through the engine compartment. These engines, known for their robust design and performance, benefit from the clamp’s ability to keep the wiring tidy and secure, which is essential for both maintenance and operational efficiency.

QSK60 CM500 Engine

The QSK60 CM500 engine, a high-performance model, also utilizes the Wire Tie Holder Clamp 3630804 to manage its extensive wiring systems. Given the complexity and the high-power output of this engine, the clamp’s role in maintaining a clean and organized wiring harness is critical. It ensures that the wiring does not interfere with moving parts or become a tripping hazard, thereby enhancing both safety and performance.

Role in Engine Systems

The 3630804 Wire Tie Holder Clamp is an essential component in the organization and maintenance of various engine systems. Its primary function is to secure and manage wiring harnesses and electrical connections, ensuring they remain in place and are protected from potential damage.

In the context of accessories and electrical components, the Wire Tie Holder Clamp plays a significant role in keeping wires and cables neatly organized. This organization is vital for preventing interference with other engine components and reducing the risk of electrical faults.

For the sensor harness mounting and electronic control module wiring harness, the clamp ensures that these sensitive components are securely fastened. This security is important for maintaining the integrity of the electrical signals they transmit, which are essential for the proper functioning of the engine’s electronic systems.

When integrated with the engine piston kit and harness mounting kit, the clamp contributes to the overall structural stability of the engine’s electrical system. By keeping wires and harnesses in their designated positions, it helps prevent them from being dislodged or damaged during engine operation.

In sensor upfit kits and ether systems, the Wire Tie Holder Clamp aids in the precise placement and protection of sensors and their associated wiring. This is particularly important in systems where accurate sensor readings are necessary for optimal engine performance.

For the electronic engine monitor and AEM harness, the clamp ensures that monitoring systems remain connected and functional. This is essential for real-time data collection and analysis, which are critical for engine diagnostics and performance tuning.

In motor starting systems and engine monitor mounting, the clamp helps maintain the reliability of starting sequences and monitoring functions by securing the necessary wiring. This is important for ensuring that the engine starts smoothly and that all monitoring systems are operational from the onset.

Lastly, in overhaul kits, the Wire Tie Holder Clamp is used to reinstall and secure wiring harnesses during engine rebuilds. This ensures that all electrical components are correctly positioned and protected, contributing to the overall success of the overhaul process.

Conclusion

The 3630804 Wire Tie Holder Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks. Its role in organizing and securing wires within the electrical system enhances the reliability, safety, and performance of the vehicle. By understanding its functionality, benefits, and proper installation and maintenance procedures, users can ensure the optimal performance of their truck’s electrical system.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Energy Efficiency of Vehicles, Douglas R Carroll, SAE International, 2020.

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.