This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

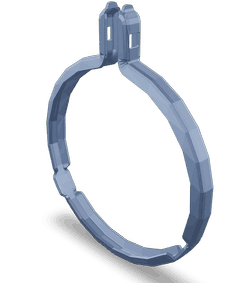

The V Band Clamp 3590606, manufactured by Cummins, is a specialized component designed for commercial trucks. It ensures the integrity and efficiency of various systems, particularly the exhaust system.

Basic Concepts of V Band Clamps

V Band Clamps are fastening devices used to secure pipes and tubing in automotive and industrial applications. They consist of a band that wraps around the pipe and a shell that compresses the band, creating a secure seal. This design allows for easy installation and removal without the need for additional tools, making them popular in applications requiring frequent maintenance or adjustments 1.

Purpose of V Band Clamp 3590606 in Truck Operation

This Cummins part is integral to the operation and maintenance of commercial trucks. It is primarily used in exhaust systems to connect various components, ensuring a tight seal that prevents leaks and maintains system efficiency. Additionally, it can be applied in other areas where secure, yet adjustable, connections are needed.

Key Features

The V Band Clamp 3590606 features a robust design that includes a stainless steel band and shell, providing durability and resistance to corrosion. Its unique V-shaped design allows for even distribution of clamping force, enhancing the seal’s integrity. The clamp is also designed for easy installation, requiring only a wrench for tightening, which simplifies maintenance procedures.

Benefits of Using V Band Clamp 3590606

Utilizing this part offers several advantages. Its design facilitates quick and easy installation, reducing downtime during maintenance. The clamp’s durability and resistance to corrosion ensure long-term reliability, even in harsh operating conditions. Furthermore, the secure seal it provides enhances the performance of truck systems by preventing leaks and maintaining system pressure.

Installation Process

Installing the V Band Clamp 3590606 involves positioning the band around the pipe, aligning it with the shell, and then using a wrench to tighten the shell until the desired clamping force is achieved. It is important to ensure that the band is evenly distributed around the pipe and that the shell is properly aligned to achieve a secure fit. Following the manufacturer’s torque specifications is recommended to ensure the clamp is tightened to the correct level.

Troubleshooting Common Issues

Common issues with V Band Clamps may include leaks or improper sealing. These problems can often be traced back to incorrect installation, such as uneven band distribution or insufficient tightening. To address these issues, it is advisable to re-evaluate the installation process, ensuring the band is correctly positioned and the shell is adequately tightened. In cases of corrosion or damage, replacing the clamp may be necessary.

Maintenance Tips

Regular maintenance of V Band Clamps is crucial for ensuring their longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage. Tightening the clamp as needed and replacing it when signs of deterioration are observed will help maintain a secure seal and prevent system leaks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 2.

Cummins V Band Clamp 3590606 Compatibility

The Cummins V Band Clamp 3590606 is a versatile component designed to fit a range of Cummins engines, ensuring secure sealing and performance. This clamp is compatible with several engine models, including:

- 4B3.9

- 6B5.9

- B4.5

- ISBE CM800

For the ISBE CM800 engine, the 3590606 clamp is particularly suited for maintaining the integrity of various connections within the engine’s system.

Additionally, the clamp is also compatible with the QSB3.9 30 CM550 engine, where it plays a crucial role in ensuring that all connections are tightly sealed, preventing leaks and maintaining engine efficiency.

The ISB CM550 engine also benefits from the use of the 3590606 V Band Clamp, ensuring that critical components remain securely fastened, contributing to the engine’s overall performance and longevity.

This clamp is engineered to meet the rigorous demands of Cummins engines, providing reliable performance across various applications.

Role of Part 3590606 V Band Clamp in Engine Systems

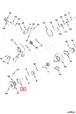

The 3590606 V Band Clamp is integral in ensuring the secure and efficient connection of various components within engine systems, particularly those involving turbochargers and heat exchangers.

In an aftermarket turbocharger setup, the V Band Clamp is used to connect the turbocharger to the exhaust manifold and the intake tract. This secure connection is essential for maintaining the integrity of the exhaust and intake systems, ensuring that there are no leaks which could affect performance and efficiency.

When dealing with a heat exchanger integrated into a 30 wastegate turbocharger system, the V Band Clamp plays a significant role in connecting the heat exchanger to both the turbocharger and the intercooler. This ensures that the charge air is effectively cooled before entering the engine, optimizing combustion efficiency and power output.

In a turbocharger HY35W configuration, the V Band Clamp is employed to attach the turbocharger to the exhaust and intake systems. Its robust design handles the high pressures and temperatures associated with turbocharger operation, providing a reliable connection that withstands the demanding conditions.

For general turbocharger applications, the V Band Clamp is used to connect the turbocharger to various components such as the exhaust manifold, intake tract, and intercooler. This ensures a leak-free system, which is vital for maintaining boost pressure and overall engine performance.

In a turbocharger kit, the V Band Clamp is often included to facilitate the installation of the turbocharger and associated components. It ensures that all connections are secure and properly sealed, which is essential for the kit’s performance and durability.

Lastly, in a turbocharger repair kit, the V Band Clamp may be used to replace worn or damaged clamps, ensuring that all connections remain secure and efficient. This is particularly important in maintaining the performance and longevity of the turbocharger system.

Conclusion

The V Band Clamp 3590606 by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential part for ensuring the integrity and efficiency of engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.