This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3527939 V Band Clamp is a component designed to secure and seal connections in various systems within commercial trucks. Its role is significant in ensuring the integrity of connections, particularly in the exhaust system, where it helps maintain efficient operation and reduce emissions 1.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to connect pipes and fittings in automotive and industrial applications. They consist of a band that wraps around the pipe and a shell that compresses the band, creating a secure and leak-proof seal. These clamps are favored for their ease of installation, reliability, and ability to provide a strong seal under varying conditions 2.

Role of the 3527939 V Band Clamp in Truck Operation

The Cummins 3527939 V Band Clamp plays a specific role in the operation of commercial trucks by securing connections in the exhaust system. It ensures that the exhaust gases are directed efficiently through the system, contributing to the overall performance and emissions control of the vehicle. Additionally, it may be used in other systems where secure and reliable connections are required 3.

Key Features

The Cummins 3527939 V Band Clamp is characterized by several key features that enhance its performance. It is constructed from durable materials that resist corrosion and wear, ensuring longevity in harsh operating environments. The design includes precise engineering to provide a consistent and reliable seal. Unique characteristics such as ease of installation and adjustment further contribute to its effectiveness 4.

Benefits of Using the 3527939 V Band Clamp

Using the Cummins 3527939 V Band Clamp offers several benefits. It provides an improved seal compared to traditional clamping methods, reducing the risk of leaks. The design allows for quick and easy installation, minimizing downtime during maintenance. Its durability ensures long-term performance, and its maintenance advantages include ease of inspection and replacement when necessary 5.

Installation Process

Installing the Cummins 3527939 V Band Clamp involves several steps to ensure optimal performance. First, the connecting pipes should be clean and free of debris. The clamp is then positioned around the pipes, and the shell is tightened using the appropriate tools until the desired compression is achieved. It is important to follow manufacturer guidelines for torque specifications to ensure a proper seal 6.

Troubleshooting Common Issues

Common issues with V Band Clamps may include leaks or improper sealing. These can often be addressed by inspecting the clamp for proper installation, ensuring that the band is evenly compressed, and checking for any damage to the clamp or connecting pipes. Re-tightening the shell or replacing damaged components may resolve these issues 7.

Maintenance Tips

To ensure the longevity and reliable performance of the Cummins 3527939 V Band Clamp, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring that the clamp remains properly tightened, and cleaning the clamp and connecting pipes to prevent corrosion and buildup. Following these maintenance practices can help prevent issues and ensure continued efficient operation 8.

Compatibility and Applications

The Cummins 3527939 V Band Clamp is designed for use in commercial truck systems, particularly within the exhaust system. It is compatible with a range of pipe sizes and materials, making it versatile for various applications. When integrating the clamp into a system, it is important to consider compatibility with other components to ensure a secure and efficient connection 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck and engine industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3527939 V Band Clamp 10.

V Band Clamp Compatibility with Cummins Engines

The V Band Clamp part number 3527939, manufactured by Cummins, is a versatile component designed to fit a range of Cummins engines. This clamp is essential for securing various parts and ensuring a tight seal, which is critical for the engine’s performance and longevity.

K50 Engines

The V Band Clamp 3527939 is compatible with the K50 engine series. This clamp ensures that components such as hoses and pipes are securely fastened, preventing leaks and maintaining system integrity.

QSK50 CM2150 and QSK50 CM2350 Engines

For the QSK50 CM2150 and QSK50 CM2350 engines, the V Band Clamp 3527939 is an integral part of the engine assembly. It is used in various applications to ensure that connections are airtight and secure, which is crucial for the efficient operation of these engines.

MCRS and K108 Engines

The V Band Clamp 3527939 also fits the MCRS and K108 engines. In these engines, the clamp is used to secure components that require a reliable seal, enhancing the overall performance and durability of the engine.

By ensuring a tight and secure fit, the V Band Clamp 3527939 plays a vital role in the functionality and maintenance of these Cummins engines.

Role of Part 3527939 V Band Clamp in Engine Systems

The part 3527939 V Band Clamp is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, enhancing both performance and reliability.

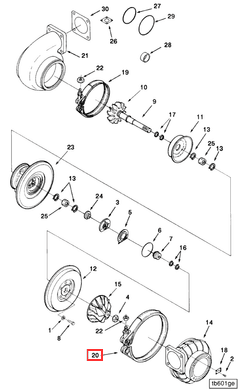

Turbocharger Systems

In turbocharger applications, the V Band Clamp secures the connections between the turbocharger and the exhaust manifold, as well as the connections to the intercooler and other intake components. This ensures a leak-free seal, which is essential for maintaining boost pressure and optimizing airflow. The clamp’s robust design handles the high temperatures and pressures generated by the turbocharger, contributing to consistent performance.

Performance Parts Integration

When integrating performance parts into an engine system, the V Band Clamp plays a significant role. It provides a reliable connection for aftermarket components such as cold air intakes, performance exhaust systems, and upgraded intercoolers. The secure fitment ensures that these parts function as intended, without the risk of disconnection or leakage, which could otherwise compromise engine performance.

Turbocharger Kits

In the context of turbocharger kits, the V Band Clamp is often used to connect various components within the kit, such as the turbocharger to the wastegate and the charge pipes to the intercooler. Its ability to create a tight seal under varying conditions ensures that the turbocharger kit operates efficiently, enhancing overall engine performance and responsiveness.

General Engine Systems

Beyond specific components, the V Band Clamp is widely used throughout engine systems to connect intake and exhaust components, ensuring a secure and leak-free environment. This is particularly important in high-performance engines where even minor leaks can significantly impact efficiency and power output.

The V Band Clamp’s versatility and reliability make it a preferred choice for both stock and modified engine setups, providing engineers and mechanics with a dependable solution for critical connections.

Conclusion

The Cummins 3527939 V Band Clamp is a critical component in the maintenance and operation of commercial truck engines. Its design and features ensure secure and reliable connections, contributing to the overall performance and efficiency of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358468.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358468.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358468.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.