This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The V Band Clamp 3527844, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is renowned for its high-quality engine and powertrain solutions. This part is integral to the efficient operation of commercial trucks, particularly in the exhaust and intake systems, ensuring reliable performance and durability.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to join pipes and fittings in various systems. They consist of a band that wraps around the pipe and a bolt that tightens the band, creating a secure seal. In the automotive industry, V Band Clamps are commonly employed in exhaust, intake, and fuel systems due to their ability to provide a robust and leak-proof connection. Their design allows for easy installation and removal, making them a preferred choice for maintenance and repair operations 1.

Purpose of V Band Clamp 3527844 in Truck Operations

The V Band Clamp 3527844 plays a significant role in the operation of commercial trucks by securing connections in the exhaust and intake systems. It ensures that these systems remain sealed, which is vital for the efficient operation of the engine. By maintaining a secure connection, the clamp helps prevent leaks that could lead to performance issues or safety hazards. Its application in these systems contributes to the overall reliability and efficiency of the truck 2.

Key Features of V Band Clamp 3527844

The V Band Clamp 3527844 is characterized by several key features that enhance its performance and durability. It is designed with precision to ensure a tight and consistent seal across various pipe diameters. The clamp is constructed from high-strength materials, providing resistance to corrosion and wear. Additionally, its design allows for easy adjustment and reusability, making it a practical choice for maintenance tasks 3.

Benefits of Using V Band Clamp 3527844

Employing the V Band Clamp 3527844 in truck maintenance and operations offers several advantages. The clamp’s design facilitates quick and easy installation, reducing downtime during maintenance procedures. Its reliability ensures a secure connection, minimizing the risk of leaks and associated performance issues. Furthermore, the efficiency of the clamp contributes to the overall performance and longevity of the truck’s exhaust and intake systems.

Installation Process

Installing the V Band Clamp 3527844 requires attention to detail to ensure a proper seal and secure connection. Begin by aligning the clamp with the pipe and fitting, ensuring that the band is centered. Next, use the provided bolt to tighten the clamp gradually, applying even pressure to avoid distortion. It is important to follow the manufacturer’s torque specifications to achieve the correct tension without over-tightening, which could damage the components.

Troubleshooting Common Issues

Frequent problems associated with V Band Clamps include leaks due to improper installation or wear and tear over time. To address these issues, inspect the clamp for signs of damage or corrosion and ensure that it is correctly aligned and tightened. Regular maintenance checks can help identify potential problems early, allowing for timely repairs or replacements to ensure the longevity and optimal performance of the clamp.

Maintenance Tips

To prolong the life of the V Band Clamp 3527844 and ensure consistent performance, regular maintenance checks are recommended. Inspect the clamp for any signs of wear, corrosion, or damage during routine maintenance intervals. Clean the clamp and surrounding areas to remove any debris that could affect its performance. Additionally, verify that the clamp is properly tightened according to the manufacturer’s specifications to maintain a secure seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing reliable and high-performance engines and components. The company’s extensive product range includes diesel and natural gas engines, as well as related technologies and services, catering to a wide array of applications across various industries.

V Band Clamp 3527844 in Cummins Engines

The V Band Clamp 3527844, manufactured by Cummins, is a crucial component in several Cummins engine models, ensuring secure and leak-proof connections in various applications. This part is integral to maintaining the integrity of engine systems by providing a tight seal around pipes and hoses.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the V Band Clamp 3527844 is used to secure connections in the exhaust system and other fluid lines. Its design allows for easy installation and removal, making it a practical choice for maintenance and repairs. The clamp’s ability to conform to the shape of the connected components ensures a reliable seal, preventing leaks and maintaining system efficiency.

Grouping of Engines

The V Band Clamp 3527844 is also compatible with other Cummins engine models that share similar design and operational requirements. These engines often feature complex piping and fluid systems that necessitate robust sealing solutions. The clamp’s versatility and effectiveness make it a preferred choice across multiple engine types, ensuring consistent performance and reliability.

Role of Part 3527844 V-Band Clamp in Engine Systems

The V-Band Clamp, specifically part 3527844, is integral to the secure and efficient operation of various engine components. Its application spans across aftermarket turbochargers, performance parts, and turbocharger repair kits, ensuring that each component functions optimally.

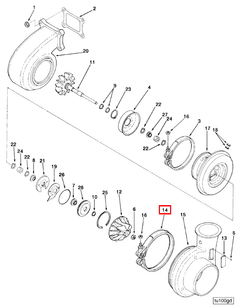

Turbocharger Integration

In turbocharger systems, the V-Band Clamp is employed to connect the turbocharger to the exhaust manifold and the intake system. This connection must be airtight to maintain the efficiency of the turbocharger. The clamp’s design allows for quick and easy installation, which is essential during maintenance or upgrades involving aftermarket turbochargers.

Performance Parts

For performance parts, the V-Band Clamp is used in custom exhaust systems and intake setups. Its flexibility and strong grip ensure that these high-performance components remain securely attached under the extreme conditions often encountered in performance driving. This reliability is vital for maintaining the integrity of the engine’s air and exhaust flow.

Turbocharger Bearing Kit and Repair Kit

When installing a turbocharger bearing kit or a turbocharger repair kit, the V-Band Clamp plays a supportive role. It ensures that the newly serviced or upgraded turbocharger is properly connected to the engine’s air and exhaust systems. This is particularly important in high-performance engines where precision and reliability are paramount.

V-Band Clamp Kits

V-Band Clamp kits often include part 3527844, providing a comprehensive solution for connecting various engine components. These kits are designed to offer a balance of ease of use and robust performance, making them a preferred choice for both professional mechanics and enthusiast engineers.

Conclusion

In summary, the V-Band Clamp, part 3527844, is a versatile component that enhances the functionality and reliability of engine systems, particularly in high-performance and aftermarket applications. Its role in securing connections in exhaust and intake systems, as well as in turbocharger and performance part integrations, underscores its importance in maintaining the efficiency and durability of commercial trucks and engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.