This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

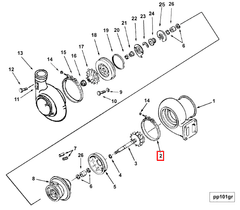

The Cummins 3522630 V Band Clamp is a component designed for use in commercial trucks. It serves a specific function in the exhaust and intake systems of these vehicles. Manufactured by Cummins, a well-established name in the automotive industry, this V Band Clamp is engineered to meet the demanding requirements of heavy-duty applications.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to join pipes and components in exhaust and intake systems. They consist of a band that wraps around the pipe and a shell that compresses the band, creating a secure seal. This design allows for easy installation and removal without the need for welding, making them a popular choice in automotive applications 1.

Role of the 3522630 V Band Clamp in Truck Operation

The 3522630 V Band Clamp plays a role in the operation of commercial trucks by securing connections in the exhaust and intake systems. Its application ensures that these systems remain sealed, which is important for the efficient operation of the engine. By maintaining a secure connection, it helps in reducing emissions and improving engine performance 2.

Key Features

The 3522630 V Band Clamp is constructed using durable materials that can withstand the high temperatures and pressures found in exhaust and intake systems. Its design includes a band and shell mechanism that provides a strong, leak-proof connection. Unique characteristics of this clamp may include specific dimensions tailored for certain applications and a design that allows for easy adjustment and reusability 3.

Benefits of Using the 3522630 V Band Clamp

Using the 3522630 V Band Clamp offers several benefits. Its design facilitates ease of installation, reducing downtime during maintenance. The materials used contribute to its durability, ensuring long-term performance even under demanding conditions. Additionally, the secure connection it provides can lead to performance enhancements in the engine system by maintaining efficient airflow 4.

Installation Process

Installing the 3522630 V Band Clamp involves positioning the band around the pipe, aligning it with the shell, and then using the appropriate tools to tighten the shell until the desired compression is achieved. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a proper seal without over-tightening, which could damage the components.

Maintenance and Troubleshooting

To maintain the 3522630 V Band Clamp, regular inspections for signs of wear or corrosion are recommended. Common issues may include leaks due to improper installation or material degradation over time. Troubleshooting typically involves checking the tightness of the clamp and ensuring that all components are in good condition. Replacement parts should be installed according to the manufacturer’s instructions to maintain system integrity.

Manufacturer - Cummins

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to quality and innovation. The company has a long history of producing reliable components for commercial vehicles, including engines, filtration systems, and aftermarket parts. Their products are designed with the aim of enhancing performance, efficiency, and durability in demanding applications.

Role of Part 3522630 V Band Clamp in Engine Systems

The Part 3522630 V Band Clamp is an essential component in various engine systems, ensuring secure and efficient connections between different parts. Here’s how it integrates with the provided components:

Turbocharger Systems

In turbocharger setups, such as the 49 State 444 Turbocharger and 50 State 444 Turbocharger, the V Band Clamp is used to connect the turbocharger to the exhaust and intake systems. This ensures a leak-free seal, which is vital for maintaining the turbocharger’s efficiency and performance. Similarly, in aftermarket turbochargers and EBM Turbochargers, the clamp provides a robust connection that can withstand high temperatures and pressures.

Engine Blocks and Short Blocks

For the Cylinder Block, Short Block 6C, Short Block 6Cart, and Short Block 6CTA, the V Band Clamp is often used in conjunction with the Turbocharger Kit to secure exhaust and intake manifold connections. This is particularly important in high-performance engines where precision and reliability are paramount.

Overhaul and Rebuild Kits

In Overhaul Kits and Rebuild Kits, the V Band Clamp is included to facilitate the reassembly of engine components. It ensures that all connections are tight and secure, which is essential for the engine’s longevity and performance.

Performance Parts

When integrating Performance Parts or Preformance Parts into an engine, the V Band Clamp plays a role in connecting upgraded components such as the Cam Follower Shaft Support and Main Bearing (Standard) Set. This ensures that these high-performance parts function optimally within the engine system.

Short Engine Kit

In a Short Engine Kit, the V Band Clamp is used to connect various components, ensuring that the engine operates smoothly and efficiently. This is particularly important in custom engine builds where precise fitting and sealing are required.

General Turbocharger Applications

For general Turbocharger applications, including the BHT4C, the V Band Clamp is used to secure the turbocharger to the engine’s exhaust and intake systems. This ensures that the turbocharger operates within its designed parameters, enhancing overall engine performance.

Core Assembly

In the Core Assembly, the V Band Clamp is utilized to connect critical components, ensuring that the assembly is both secure and efficient. This is essential for the core’s functionality and the engine’s overall performance.

Engine Piston Kit

While the Engine Piston Kit primarily focuses on the internal components of the engine, the V Band Clamp is used externally to ensure that all connections to the piston assembly are secure, contributing to the engine’s smooth operation.

By understanding the role of the Part 3522630 V Band Clamp in these various engine systems, engineers and mechanics can ensure that all connections are secure, efficient, and contribute to the overall performance and reliability of the engine.

Conclusion

The Cummins 3522630 V Band Clamp is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its design and construction ensure secure, efficient connections that contribute to engine performance and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.