3348663

Injector Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Injector Clamp 3348663 is a component designed for use in heavy-duty truck engines. Cummins, a prominent figure in the automotive industry, is known for its diesel engines and components. This part is significant in the context of heavy-duty truck engines as it plays a role in the fuel injection system, contributing to the overall efficiency and performance of the engine 1.

Function and Operation

This Cummins part operates within the fuel injection system of a truck engine by securing the injector in place. This ensures that the injector remains stable during engine operation, which is vital for consistent and precise fuel delivery. Proper fuel delivery is essential for the engine’s combustion process, directly influencing its performance and efficiency 2.

Key Features

The Injector Clamp 3348663 is designed with specific characteristics that enhance its functionality and durability. It is constructed from materials that offer corrosion resistance, which is important for withstanding the harsh environments often encountered in heavy-duty truck applications. Additionally, the clamp is engineered for durability, ensuring it can withstand the rigors of engine operation over an extended period. Ease of installation is another notable feature, allowing for straightforward replacement or maintenance procedures 3.

Benefits

The use of the Injector Clamp 3348663 in a truck engine’s fuel injection system offers several advantages. It contributes to improved fuel efficiency by ensuring that the injector is securely in place, allowing for precise fuel delivery. This precision in fuel delivery can also lead to reduced emissions, as the engine operates more efficiently. Furthermore, the stable positioning of the injector enhances engine performance, ensuring smooth and reliable operation 4.

Installation Process

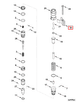

Installing the Injector Clamp 3348663 requires following a specific procedure to ensure proper function and safety. The process involves removing the old clamp, if present, and cleaning the injector and surrounding area. The new clamp is then positioned around the injector and secured in place. It is important to use the correct tools and follow safety precautions during installation to avoid damage to the injector or surrounding components.

Maintenance Tips

To ensure the longevity and optimal performance of the Injector Clamp 3348663, routine maintenance practices are recommended. This includes regular inspection of the clamp for signs of wear or corrosion, and cleaning as necessary to remove any buildup that could affect its function. Adhering to manufacturer-recommended inspection intervals and maintenance procedures will help maintain the clamp’s effectiveness over time.

Troubleshooting Common Issues

Injector clamps, including the 3348663, may encounter issues such as corrosion, wear, or improper installation. Identifying these problems early can prevent more significant engine issues. Troubleshooting methods may involve visual inspection for signs of damage or corrosion, ensuring the clamp is correctly installed, and replacing the clamp if necessary to maintain engine performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its diesel engines and components. With a history of innovation and quality, Cummins offers a wide range of products designed for various applications, from heavy-duty trucks to industrial equipment. The company’s reputation for reliability and performance makes its components, like the Injector Clamp 3348663, a preferred choice for professionals in the automotive and heavy-duty truck sectors.

Compatibility with Cummins Engines

The Injector Clamp part number 3348663 is compatible with several Cummins engine models, including the QSK19 CM500, QSK45 CM500, QSK78 CM500, QSK60 CM500, and QSK60G. These engines are part of the Cummins QSK series, known for their robust design and high performance in various applications, including marine, power generation, and industrial use. The clamp ensures that the injectors remain firmly attached under the high pressures and temperatures typical of these engines.

Understanding the Role of Part 3348663 Injector Clamp in Engine Systems

The Injector Clamp, identified by part number 3348663, is a component in the orchestration of various engine systems. Its primary function is to secure the injector in place, ensuring a stable and reliable connection within the fuel system. This clamp is integral to maintaining the integrity of the injector plumbing, which is vital for the precise delivery of fuel to the combustion chamber.

When properly installed, this part contributes to the overall performance of the engine by ensuring that the injector remains firmly in position. This stability is particularly important during the operation of the engine, where vibrations and thermal expansions can otherwise dislodge or misalign the injector.

The clamp works in conjunction with the cylinder head, where the injector is typically mounted. By providing a secure fit, the clamp helps to prevent leaks in the fuel system, which could otherwise lead to a loss of fuel pressure and inefficient combustion. This is especially important in high-performance engines where fuel delivery precision can significantly affect engine output and efficiency.

Furthermore, the Injector Clamp plays a role in the interaction between the injector and the camshaft. In engines where the camshaft controls the opening and closing of the injectors, a secure clamp ensures that the injector operates in sync with the camshaft’s movements, contributing to the engine’s timing and performance.

Conclusion

In summary, the Injector Clamp (part 3348663) is a key component that enhances the reliability and performance of the fuel system by ensuring a secure and stable connection for the injector. Its role in maintaining the integrity of the injector plumbing and the overall engine performance is significant.

-

Nunney, M.J. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.