This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

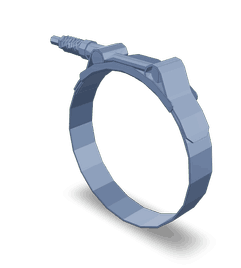

The Cummins 3285819 T-Bolt Hose Clamp is a component designed for use in commercial trucks. It serves to secure hoses and pipes within the vehicle’s systems, ensuring that fluids are transported efficiently and safely. The clamp’s role is significant in maintaining the integrity of the truck’s fluid systems, which are vital for the vehicle’s operation 1.

Basic Concepts of T-Bolt Hose Clamps

T-Bolt Hose Clamps are mechanical fasteners used to create a seal around hoses and pipes. They consist of a band that wraps around the hose and a T-shaped bolt that tightens the band, creating a secure fit. These clamps are widely used in automotive and industrial applications due to their reliability and ease of use 2.

Purpose and Role in Truck Operation

This Cummins part plays a role in the operation of commercial trucks by securing hoses and pipes within the vehicle’s fluid systems. This ensures that fluids such as coolant, fuel, and hydraulic fluid are transported without leaks, which is important for the truck’s performance and safety. The clamp helps maintain the pressure and flow of these fluids, contributing to the overall efficiency of the truck’s systems 3.

Key Features

The T-Bolt Hose Clamp is constructed from durable materials, typically stainless steel or a high-strength polymer, which provide resistance to corrosion and wear. Its design includes a T-shaped bolt that allows for easy tightening and adjustment, ensuring a secure fit on various hose diameters. The clamp also features a band that is engineered to distribute pressure evenly around the hose, minimizing the risk of damage to the hose material 4.

Benefits

This part offers several benefits. Its durable construction ensures long-term use, even in demanding commercial truck environments. The ease of installation is another advantage, as the T-shaped bolt allows for quick and secure clamping without the need for specialized tools. Additionally, the clamp’s design contributes to the performance of the truck’s fluid systems by providing a reliable seal that prevents leaks and maintains fluid pressure.

Installation Process

To install the T-Bolt Hose Clamp, first, ensure that the hose is clean and free of any debris. Place the clamp around the hose, ensuring that the band is centered. Insert the T-shaped bolt through the band and begin tightening it using a wrench. Continue tightening until the hose is securely clamped, but avoid over-tightening, which could damage the hose. Finally, check for any leaks by running the system and observing the connection.

Troubleshooting Common Issues

Common issues with T-Bolt Hose Clamps include leaks, which can be caused by improper installation or wear on the clamp or hose. To address leaks, first, ensure that the clamp is properly tightened. If the leak persists, inspect the hose for damage and replace it if necessary. Additionally, check the condition of the clamp and replace it if there are signs of wear or corrosion.

Maintenance Tips

Regular maintenance of the T-Bolt Hose Clamp is important to ensure its longevity and optimal performance. Inspect the clamp and hose regularly for signs of wear, corrosion, or damage. Clean the clamp and surrounding area to remove any debris that could affect its function. If the clamp shows signs of wear or if the hose needs replacement, it is advisable to replace the clamp to maintain a secure and leak-free connection.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3285819 T-Bolt Hose Clamp, which is designed to meet the demanding requirements of commercial truck applications.

Compatibility

This part is compatible with several Cummins engine models, including the QSK19, CM2350, and K144G engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications such as marine and industrial settings. The clamp’s precision fit ensures that hoses remain securely attached, preventing leaks and maintaining system integrity.

Role in Various Components

In package systems, the T-Bolt Hose Clamp ensures secure connections between hoses and fittings. This is particularly important in applications where vibrations and movements are common, as it maintains the integrity of the fluid or gas pathways. For railcar installations, the clamp is utilized to connect hoses in fuel, pneumatic, and hydraulic systems. Its robust construction withstands the harsh environments and dynamic conditions typical of rail transport. In plumbing systems, the clamp is employed to join hoses in both residential and commercial settings. Within air cleaner systems, the clamp plays a significant role in maintaining airtight seals between hoses and filters.

Conclusion

The Cummins 3285819 T-Bolt Hose Clamp is a vital component in the maintenance and operation of commercial trucks. Its durable construction, ease of installation, and reliable performance make it an essential part for securing hoses and pipes within the vehicle’s fluid systems. Regular maintenance and proper installation are key to ensuring the clamp’s longevity and optimal performance.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.