This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

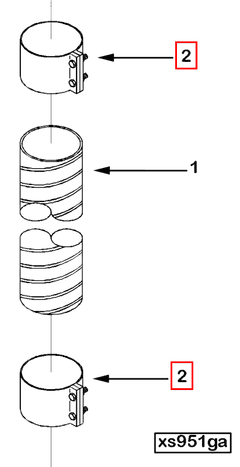

The Cummins 3283436 Tube Clamp is a specialized component designed for heavy-duty truck maintenance and operation. It plays a significant role in the efficiency and reliability of the vehicle by securing and connecting tubing systems. Understanding its purpose and functionality is essential for those involved in the maintenance or operation of heavy-duty trucks.

Basic Concepts of Tube Clamps

Tube clamps are essential devices in automotive and industrial applications for securing and connecting tubing systems. They ensure efficient transportation of fluids or gases by providing a tight seal around the tubing, preventing leaks. Tube clamps are available in various designs and materials, tailored to specific applications based on the type of tubing and operating environment 1.

Purpose of the Cummins 3283436 Tube Clamp

The Cummins 3283436 Tube Clamp is designed to secure and connect tubing within a truck’s systems, particularly in components and systems where tubing is used to transport fluids or gases. Its design and construction are tailored to meet the demands of heavy-duty truck environments, ensuring reliable performance under varying conditions 2.

Key Features

This Cummins part is characterized by its robust design and construction. It is made from materials that offer durability and resistance to corrosion, ensuring long-term performance. The clamping mechanism is designed to provide a secure fit around the tubing, minimizing the risk of leaks. Unique attributes of this tube clamp include its ease of installation and adjustment, contributing to its efficiency and reliability 3.

Benefits of Using the Cummins 3283436 Tube Clamp

Utilizing the Cummins 3283436 Tube Clamp offers several advantages. It enhances the reliability of the tubing connections, reducing the likelihood of leaks and ensuring efficient fluid or gas transport. The design of the clamp facilitates easy installation and adjustment, contributing to maintenance efficiency. Additionally, its durable construction prolongs the lifespan of the tubing connections, offering cost-effective maintenance solutions.

Installation Process

Installing the Cummins 3283436 Tube Clamp requires following a series of steps to ensure a secure fit. Begin by preparing the tubing and ensuring it is clean and free from debris. Position the clamp around the tubing and use the appropriate tools to tighten it, ensuring an even and secure fit. It is important to follow best practices during installation to avoid over-tightening, which can damage the tubing or the clamp itself.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the clamp or tubing. Troubleshooting steps may involve inspecting the clamp and tubing for damage, ensuring the clamp is correctly positioned and tightened, and replacing any worn or damaged components as necessary.

Maintenance Tips

Regular maintenance of the Cummins 3283436 Tube Clamp is key to prolonging its lifespan and ensuring reliable performance. This includes routine inspections for signs of wear or damage, cleaning the clamp and tubing to remove any buildup, and replacing the clamp if it shows signs of significant wear. Adhering to these maintenance practices helps maintain the integrity of the tubing connections and the overall efficiency of the truck’s systems.

Compatibility and Applications

The Cummins 3283436 Tube Clamp is designed for use in heavy-duty trucks, where it is commonly applied in various systems and components that utilize tubing. Its compatibility with different types of tubing and its robust design make it suitable for a wide range of applications within the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and emission solutions. Cummins is recognized for its dedication to sustainability, efficiency, and technological advancement in the automotive and industrial sectors.

Role of Part 3283436 Tube Clamp in Engine Systems

The Part 3283436 Tube Clamp is an essential component in ensuring the secure and efficient connection of various tubes within engine systems. Specifically, in the context of exhaust connections, this tube clamp plays a significant role.

Exhaust Connection

In exhaust systems, the tube clamp is utilized to maintain a tight seal between the exhaust manifold and the exhaust pipe. This seal is vital for directing exhaust gases away from the engine efficiently. The tube clamp ensures that there are no leaks in the system, which could lead to a loss of performance and increased emissions. Additionally, it helps in withstanding the high temperatures and pressures associated with exhaust gases, contributing to the durability and reliability of the exhaust connection.

The secure fitting provided by the tube clamp also aids in reducing vibrations that can occur due to the engine’s operation, thereby enhancing the overall stability of the exhaust system. This is particularly important in high-performance engines where the exhaust system is subjected to greater stress.

Moreover, the tube clamp facilitates easier maintenance and replacement of exhaust components. By providing a quick-release mechanism, it allows mechanics to disconnect and reconnect tubes without the need for complex tools, streamlining the repair process and reducing downtime.

Conclusion

In summary, the Cummins 3283436 Tube Clamp is integral to the functionality and efficiency of exhaust connections in engine systems, ensuring a secure, leak-free, and stable connection that can withstand the rigors of engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.