3089309

t Bolt Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The T-Bolt Clamp 3089309, manufactured by Cummins, is a critical component in the commercial truck industry. This clamp is essential for securing various components in commercial trucks, ensuring efficient vehicle operation.

Basic Concepts of T-Bolt Clamps

A T-Bolt Clamp is a fastener used in mechanical systems to secure components. It features a bolt with a T-shaped head that fits into a slot, allowing for easy tightening and loosening. The clamp applies pressure to secure components, ensuring they remain in place under various conditions.

Purpose of the 3089309 T-Bolt Clamp in Truck Operation

The 3089309 T-Bolt Clamp is used in commercial trucks to secure components within various systems. It ensures parts remain fixed, reducing the risk of movement or detachment during operation, which can lead to inefficiencies or safety concerns.

Key Features

This Cummins part is constructed from durable materials, ensuring longevity and resistance to wear. Its T-shaped bolt provides a secure fit within the designated slot, enhancing functionality. The clamp’s ease of installation and adjustment allows for quick and efficient use in maintenance procedures.

Benefits of Using the 3089309 T-Bolt Clamp

Utilizing this part offers several advantages. Its durable construction ensures long-term use, while its design facilitates easy installation. The clamp’s reliability in securing truck components contributes to the overall efficiency and safety of the vehicle.

Installation Process

To install the T-Bolt Clamp, ensure the components to be secured are properly aligned. Insert the T-shaped bolt into the slot and use the appropriate tool to tighten it, ensuring a secure fit. It is important to follow best practices during installation to ensure the clamp functions as intended.

Troubleshooting Common Issues

Common issues with T-Bolt Clamps may include loosening over time or corrosion. To address these problems, regular inspections are recommended. If loosening is detected, retighten the clamp. In cases of corrosion, cleaning the affected area and applying a protective coating can help prevent further deterioration.

Maintenance Tips

Regular maintenance of the 3089309 T-Bolt Clamp is recommended to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage and cleaning the clamp to remove any debris or buildup that may affect its function.

Compatibility and Applications

The 3089309 T-Bolt Clamp is designed for use in various commercial truck systems. Its compatibility with other components ensures it can be integrated into different truck models, contributing to the versatility of its application.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. The company’s history of innovation and commitment to quality has established it as a trusted name among professionals in the field 1.

T-Bolt Clamp (Part 3089309) in Cummins Engines

The T-Bolt Clamp, identified by the part number 3089309, is a critical component in several Cummins engines, ensuring the secure fastening of various parts. This clamp is designed to maintain the integrity and alignment of engine components, contributing to the overall performance and longevity of the engine.

Application in Cummins Engines

QSK45 CM500

The T-Bolt Clamp is integral to the QSK45 CM500 engine, where it plays a pivotal role in securing specific parts. Its design allows for precise alignment and firm attachment, which is essential for the engine’s operational efficiency and durability. The clamp’s robust construction ensures it can withstand the high stresses and vibrations typical in engine environments.

QSK Series

In the broader QSK series, the T-Bolt Clamp is utilized across various models, including the QSK45 CM500. Its application in these engines underscores its versatility and importance in maintaining the structural integrity of the engine. The clamp’s ability to provide a secure and stable connection is vital for the smooth operation of the engine’s components.

CM Series

Similarly, in the CM series, the T-Bolt Clamp is a key component, ensuring that parts are fastened securely. Its design and material are chosen to meet the stringent requirements of these engines, providing a reliable solution for fastening needs.

By integrating the T-Bolt Clamp into these engines, Cummins ensures that the engines operate with maximum efficiency and reliability, leveraging the clamp’s ability to maintain precise alignment and secure fastening.

Role of Part 3089309 T-Bolt Clamp in Engine Systems

The part 3089309 T-Bolt Clamp is instrumental in securing various components within engine systems, ensuring optimal performance and safety. In the context of turbocharger arrangements, this clamp plays a significant role in maintaining the integrity of the system.

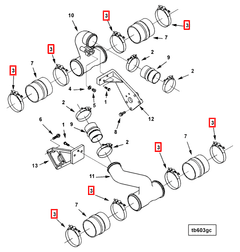

Turbocharger Arrangement

In turbocharger setups, the T-Bolt Clamp is used to secure the exhaust and intake piping to the turbocharger housing. This ensures that the connections remain tight and leak-free, which is essential for maintaining the efficiency of the turbocharger. The clamp helps in withstanding the high pressures and temperatures associated with the exhaust gases, thereby contributing to the overall reliability of the turbocharger system.

Turbocharger Integration

When integrating a turbocharger into an engine system, the T-Bolt Clamp is employed to fasten the intercooler piping and other ancillary components. This secure attachment is vital for preventing vibrations and ensuring that the turbocharger operates within its designed parameters. The clamp’s robust design allows it to handle the dynamic forces generated during engine operation, thus enhancing the durability of the turbocharger integration.

Turbocharger Maintenance

During maintenance procedures involving the turbocharger, the T-Bolt Clamp facilitates easy disassembly and reassembly of components. Its design allows for quick release and retightening, which is beneficial during routine inspections and repairs. This feature not only saves time but also reduces the risk of damaging sensitive turbocharger parts during service.

Conclusion

The 3089309 T-Bolt Clamp is a key component in ensuring the secure and efficient operation of turbocharger systems within engine arrangements. Its application across various connections and integrations underscores its importance in maintaining the performance and longevity of turbocharged engines.

-

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.