This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3086072 Tube Clamp is a specialized component designed for use in commercial truck operations. Its purpose is to secure and connect tubing systems within various truck applications. The significance of this tube clamp lies in its ability to ensure the integrity and efficiency of these systems, contributing to the overall performance and reliability of commercial trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold and connect tubing in automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a secure and leak-proof connection. In automotive applications, tube clamps are vital for maintaining the integrity of fluid and gas transport systems, ensuring that these systems operate efficiently and safely 1.

Purpose of the Cummins 3086072 Tube Clamp

The Cummins 3086072 Tube Clamp is specifically designed to play a role in the operation of commercial trucks by securing tubing in various systems. Its applications include fuel lines, exhaust systems, and hydraulic lines. By providing a reliable connection, this tube clamp helps maintain the efficiency and safety of these critical systems.

Key Features

The Cummins 3086072 Tube Clamp boasts several key features that enhance its performance and durability. These include a robust material composition, typically made from high-strength materials to withstand the rigors of commercial truck environments. The design elements of the clamp ensure a secure fit, while any unique attributes, such as corrosion resistance or ease of installation, further contribute to its effectiveness.

Benefits

Using the Cummins 3086072 Tube Clamp offers several benefits. It provides improved system integrity by ensuring secure and leak-proof connections. The design of the clamp allows for ease of installation, reducing downtime during maintenance. Additionally, its durable construction ensures long-term reliability, making it a cost-effective solution for commercial truck operators.

Installation Process

Proper installation of the Cummins 3086072 Tube Clamp involves several steps to ensure a secure fit. Begin by cleaning the tubing to remove any debris or contaminants. Position the clamp around the tubing and use the appropriate tools to tighten it until the desired compression is achieved. Following best practices, such as ensuring even pressure distribution, will help maintain the integrity of the connection.

Troubleshooting Common Issues

Common problems with tube clamps may include leaks or improper sealing. To address these issues, first, inspect the clamp and tubing for any signs of damage or wear. Ensure that the clamp is properly tightened and that the tubing is correctly seated within the clamp. If leaks persist, consider replacing the clamp or tubing to restore system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3086072 Tube Clamp is essential for ongoing performance and longevity. Inspect the clamp and tubing at regular intervals for signs of wear or corrosion. Cleaning the clamp and tubing to remove any buildup of dirt or debris will help prevent issues. Following these maintenance practices will ensure the continued reliability of the tube clamp.

Role in Truck Systems

The Cummins 3086072 Tube Clamp integrates within various truck systems, such as fuel lines, exhaust systems, and hydraulic lines. By providing secure and reliable connections, it contributes to the overall efficiency and safety of these systems. Its role in maintaining the integrity of fluid and gas transport systems is vital for the optimal performance of commercial trucks.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a diverse product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The Cummins 3086072 Tube Clamp is a testament to the company’s commitment to providing high-quality components that enhance the performance and reliability of commercial trucks.

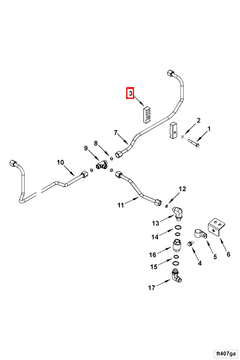

Tube Clamp 3086072 in Cummins Engines

The Tube Clamp 3086072, manufactured by Cummins, is an essential component in various Cummins engine models. This part is integral to the engine’s structure, ensuring the integrity and functionality of the system it supports.

QSK19 CM500

In the QSK19 CM500 engine, the Tube Clamp 3086072 plays a role in securing and stabilizing the tubing that carries fluids or gases within the engine. Its design ensures that the connections remain tight and leak-proof, which is vital for maintaining engine performance and safety.

Grouping of Engines

The Tube Clamp 3086072 is compatible with several Cummins engines, including but not limited to, the QSK19 CM500. This part’s versatility allows it to fit seamlessly into different engine configurations, providing a reliable solution for securing tubing across various applications.

Role of Part 3086072 Tube Clamp in Engine Systems

The 3086072 Tube Clamp is a component in the secure and efficient operation of various engine systems, particularly in the context of fuel and general plumbing applications.

In fuel plumbing systems, the Tube Clamp ensures that fuel lines are tightly secured to their respective fittings. This is important for maintaining the integrity of the fuel delivery system, preventing leaks, and ensuring consistent fuel pressure. The clamp’s design allows it to accommodate slight misalignments between the tube and fitting, which can occur due to thermal expansion or vibration, thereby enhancing the reliability of the fuel system.

Within general plumbing applications, the 3086072 Tube Clamp plays a similar role but is utilized in a broader range of systems. It is commonly employed in coolant systems, brake lines, and other hydraulic systems where fluid transfer is essential. The clamp’s ability to provide a leak-proof seal is vital for the safe and efficient operation of these systems. It helps in withstanding the pressure variations and temperature fluctuations that are typical in engine environments.

Overall, the 3086072 Tube Clamp contributes to the robustness and safety of engine systems by ensuring that all fluid-carrying tubes are securely attached to their fittings, thereby preventing potential failures and enhancing the overall performance and longevity of the engine.

Conclusion

The Cummins 3086072 Tube Clamp is a critical component for maintaining the integrity and efficiency of various systems in commercial trucks and Cummins engines. Its robust design, ease of installation, and durable construction make it a reliable choice for securing tubing in fuel, exhaust, and hydraulic systems. Regular maintenance and proper installation are key to ensuring the long-term reliability and performance of this essential part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.