This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

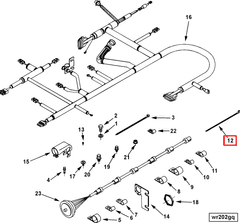

The Cummins 3074519 Wire Tie Clamp is a component designed to secure wires and hoses in commercial trucks. Its role in maintaining the integrity and organization of the vehicle’s wiring and hose systems is significant, contributing to both the safety and efficiency of truck operations 4.

Basic Concepts of Wire Tie Clamps

Wire tie clamps are devices used to bundle and secure wires and hoses. They function by compressing around the bundle, holding the components in place and preventing them from moving or vibrating excessively. In automotive and industrial settings, these clamps are vital for managing cables and hoses, ensuring they remain organized and protected from damage 1.

Purpose of the 3074519 Wire Tie Clamp

This Cummins part is specifically designed to aid in the securement of wires and hoses within commercial trucks. By keeping these components in place, it helps maintain the structural integrity of the truck’s electrical and fluid systems, reducing the risk of damage from movement or environmental factors 2.

Key Features

The 3074519 boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to wear. Its design includes elements that allow for easy installation and adjustment, accommodating various bundle sizes. Additionally, the clamp features a locking mechanism that secures it in place once tightened, providing a stable and reliable hold 3.

Benefits of Using the 3074519 Wire Tie Clamp

Utilizing this part offers several advantages. It improves wire management by keeping cables and hoses organized and protected. The clamp’s durable construction ensures enhanced longevity, while its design facilitates ease of installation, making it a practical choice for maintenance tasks 4.

Installation Process

Installing the 3074519 involves several steps to ensure it is securely and effectively applied. Begin by gathering the necessary tools, which may include a screwdriver or pliers, depending on the specific design of the clamp. Position the clamp around the bundle of wires or hoses, ensuring it is centered and aligned. Tighten the clamp using the appropriate tool, adjusting as needed to achieve a snug fit without over-tightening, which could damage the components 1.

Troubleshooting Common Issues

Common issues with wire tie clamps may include loosening over time or difficulty in installation. To address these problems, regular inspections are recommended to ensure the clamps remain secure. If a clamp becomes loose, it should be re-tightened or replaced if damaged. Ensuring the correct size clamp is used for the bundle can also prevent installation difficulties 2.

Maintenance Tips

To ensure the longevity and consistent performance of the 3074519, regular maintenance is advised. This includes periodic inspections to check for signs of wear or damage. If a clamp shows signs of deterioration or if wires and hoses have shifted, the clamp should be adjusted or replaced as necessary. Keeping the area around the clamp clean and free of debris can also contribute to its effectiveness 3.

Compatibility and Applications

This part is designed for use in various truck models and systems, demonstrating its versatility and widespread applicability in the commercial truck industry.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its extensive product range and commitment to quality and innovation. With a history of delivering reliable and high-performance components, Cummins continues to be a trusted name in the field, emphasizing its dedication to advancing technology and meeting the needs of its customers 4.

Wire Tie Clamp 3074519 Compatibility with Cummins Engines

The Wire Tie Clamp 3074519, manufactured by Cummins, is designed to secure and organize wiring harnesses and other electrical components in various Cummins engines. This part is essential for maintaining a clean and efficient engine compartment, ensuring that wires are neatly bundled and do not interfere with moving parts or other critical components 1.

C8.3 G, ISM CM570, K19, K38, K50

In engines such as the C8.3 G, ISM CM570, K19, K38, and K50, the Wire Tie Clamp 3074519 is used to manage the extensive wiring that runs throughout the engine bay. These engines, known for their robust performance and reliability, benefit from the clamp’s ability to keep wiring organized, which aids in maintenance and troubleshooting 2.

M11 CELECT, M11 CELECT PLUS, M11 MECHANICAL

For the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines, the Wire Tie Clamp 3074519 plays a crucial role in managing the complex wiring systems. These engines are equipped with advanced electronic controls and sensors, and the clamp helps ensure that all wiring is securely fastened and easily accessible for service 3.

N14 CELECT PLUS

The N14 CELECT PLUS engine, with its high power output and sophisticated control systems, relies on the Wire Tie Clamp 3074519 to maintain an organized and efficient engine compartment. The clamp helps prevent wire chafing and damage, contributing to the engine’s overall reliability and longevity 4.

QSK19 CM500, QSK45 CM500, QSK60 CM500, QSM11 CM570, QST30 CM552

In the QSK19 CM500, QSK45 CM500, QSK60 CM500, QSM11 CM570, and QST30 CM552 engines, the Wire Tie Clamp 3074519 is used to manage the extensive wiring networks. These engines, designed for heavy-duty applications, benefit from the clamp’s ability to keep wiring organized and secure, ensuring that the engine operates smoothly and efficiently 1.

Role of Part 3074519 Wire Tie Clamp in Engine Systems

The part 3074519 Wire Tie Clamp is instrumental in maintaining the integrity and organization of various wiring systems within engine assemblies. Its application spans across multiple components, ensuring that wiring remains secure, reducing the risk of electrical faults, and enhancing overall system reliability 2.

Integration with Wiring Components

- Wiring (Top Level Assembly Harness): The Wire Tie Clamp is used to secure the wiring within the top-level assembly harness. This ensures that the wires remain neatly bundled, preventing chafing or abrasion against other engine components 3.

- Brace and Harness Assembly: In the brace and harness assembly, the clamp helps in maintaining the structural integrity of the wiring. It prevents wires from shifting or coming loose, which could lead to intermittent connections or failures 4.

- Electronic Control Module Harness: For the electronic control module harness, the clamp is essential in keeping the wiring organized. This is particularly important as it ensures that signals to and from the electronic control module are transmitted without interference 1.

- Wiring (TLA, BUS): In systems utilizing TLA (Twisted Pair Link) and BUS wiring, the clamp ensures that the twisted pairs remain intact and that the bus wiring is securely fastened, reducing the likelihood of signal degradation 2.

Application in Kits and Modules

- HHP 12V VLV/ELEC Kit and HHP 24V VLV/ELEC Kit: These kits often include complex wiring configurations. The Wire Tie Clamp is used to secure the wiring, ensuring that the high-voltage and electronic components within these kits function correctly without risk of electrical shorts 3.

- Engine Control Module: Within the engine control module, the clamp is used to organize and secure the wiring that connects various sensors and actuators to the module. This is vital for maintaining accurate data transmission and reliable engine performance 4.

Use in Specialized Systems

- N14 12V Pressure-Time Centinel Kit and N14 24V Hardware-Pressure-Time Valve/Mounting Kit: These kits involve pressure and time-sensitive components. The Wire Tie Clamp ensures that the wiring associated with these components is securely fastened, preventing any movement that could affect the precision of the system 1.

- Oil Replenishing System: In systems where oil replenishment is automated, the clamp secures the wiring that controls the oil flow sensors and pumps. This ensures consistent oil levels and prevents potential engine damage due to wiring issues 2.

General Wiring Applications

- Wiring Harness and Wiring Top Level Assembly Harness: Across various wiring harnesses and top-level assembly harnesses, the clamp is used to bundle and secure wires. This not only aids in maintaining a tidy installation but also protects the wiring from physical damage and environmental factors 3.

Conclusion

In summary, the part 3074519 Wire Tie Clamp plays a significant role in the organization, protection, and reliability of wiring within engine systems. Its application across different components ensures that electrical connections remain secure and functional, contributing to the overall performance and longevity of the engine 4.

-

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ ↩ ↩ ↩ ↩ ↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ ↩ ↩ ↩ ↩ ↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ ↩ ↩ ↩ ↩ ↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.