This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

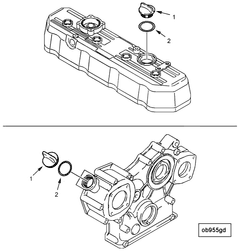

The Cummins 4900388 Filler Cap is a component designed for use in commercial trucks. Its primary role is within the vehicle’s fuel system, where it facilitates the addition of fuel to the tank while ensuring that spills are minimized and contaminants are kept out. This part is integral to maintaining the efficiency and safety of the fuel system in heavy-duty applications 1.

Purpose and Function

The filler cap serves a dual purpose in the truck’s fuel system. It allows for the safe and efficient addition of fuel to the tank, ensuring that the process is streamlined and user-friendly. Additionally, it acts as a barrier, preventing spills during refueling and blocking contaminants from entering the fuel tank. This function is vital for maintaining the purity of the fuel, which directly impacts the performance and longevity of the engine 2.

Key Features

The Cummins 4900388 Filler Cap is characterized by its robust design and the materials used in its construction. It is engineered to withstand the rigors of commercial use, featuring a durable build that resists wear and tear. The cap is made from high-quality materials that ensure it can handle the pressures and temperatures associated with diesel fuel. Its design includes features that enhance its performance, such as a secure locking mechanism to prevent accidental opening and a venting system that allows for safe pressure release during refueling 3.

Benefits

The use of the Cummins 4900388 Filler Cap offers several advantages. It contributes to the integrity of the fuel system by ensuring that fuel is added without contamination. The ease of use it provides makes refueling a straightforward process, reducing the time and effort required. Furthermore, its durable construction ensures long-term reliability, minimizing the need for frequent replacements and maintenance 4.

Installation and Usage

Proper installation of the Cummins 4900388 Filler Cap is crucial for its optimal performance. It should be securely fitted to the fuel tank to ensure a tight seal. Users are advised to follow the manufacturer’s guidelines for installation to avoid common pitfalls that could lead to leaks or improper function. When in use, it is important to ensure that the cap is properly closed after refueling to maintain the integrity of the fuel system.

Maintenance and Care

Regular maintenance of the Cummins 4900388 Filler Cap is recommended to ensure its continued effectiveness. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could affect its function, and ensuring that the locking mechanism operates correctly. If the cap shows signs of significant wear or if it no longer forms a secure seal, consideration should be given to its replacement to maintain the safety and efficiency of the fuel system.

Troubleshooting Common Issues

Common issues with the Cummins 4900388 Filler Cap may include leaks or difficulty in opening or closing the cap. Leaks can often be traced to a poor seal, which may be addressed by ensuring the cap is correctly installed or by replacing worn gaskets. Difficulty in operation may require cleaning or lubrication of the moving parts. In cases where the cap is damaged, replacement is the recommended course of action.

Safety Considerations

When handling and maintaining the Cummins 4900388 Filler Cap, it is important to observe safety precautions to avoid fuel spills and ensure personal safety. This includes working in a well-ventilated area, wearing appropriate protective gear, and ensuring that the vehicle’s engine is off during maintenance to prevent accidental starts. Additionally, care should be taken to avoid static electricity, which can be a hazard when working with flammable fuels.

Environmental Impact

The Cummins 4900388 Filler Cap plays a role in environmental protection by preventing fuel spills, which can contaminate soil and water sources. By ensuring that the fuel system remains sealed and secure, it helps in reducing the risk of accidental releases. Furthermore, its design contributes to the efficient operation of the vehicle, potentially leading to reduced emissions through optimized fuel consumption.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in engine manufacturing is reflected in its wide range of products, designed to meet the demanding requirements of commercial and industrial applications.

Conclusion

The Cummins 4900388 Filler Cap is a critical component in the maintenance and operation of commercial truck fuel systems. Its design and features ensure the safe and efficient addition of fuel, while also protecting the system from contamination and spills. Regular maintenance and proper usage are essential to maximize the benefits of this part, contributing to the overall performance and longevity of the vehicle’s engine.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components (Springer, 2014).

↩ -

Hannes Hick, Klaus Kupper, and Helfried Sorger, Systems Engineering for Automotive Powertrain Development (Springer, 2021).

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training, Second Edition (Routledge, 2022).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.