This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

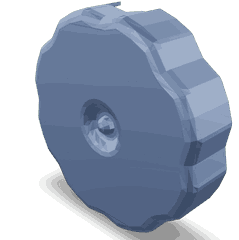

The Cummins 3864276 Filler Cap is a component designed for use in commercial trucks, specifically within the fuel system. Its primary role is to facilitate the addition of fuel to the tank while ensuring that spills and contamination are minimized. This part is integral to maintaining the efficiency and safety of the vehicle’s fuel system.

Purpose and Function

The Cummins 3864276 Filler Cap serves a function in the truck’s fuel system by allowing fuel to be added to the tank in a controlled manner. It is engineered to create a seal that prevents fuel from spilling out during the refueling process. Additionally, the cap is designed to keep contaminants such as dirt, water, and other debris from entering the fuel tank, which could potentially harm the engine’s performance 1.

Key Features

The Cummins 3864276 Filler Cap is constructed with a focus on durability and performance. It is made from high-quality materials that are resistant to the corrosive effects of fuel. The design of the cap includes a secure locking mechanism that ensures a tight seal is maintained during transportation, reducing the risk of fuel leakage. Furthermore, the cap is designed to be user-friendly, allowing for easy operation during refueling.

Benefits

The use of the Cummins 3864276 Filler Cap offers several advantages. It enhances the integrity of the fuel system by providing a reliable barrier against external contaminants. The cap’s design also contributes to ease of use, making the refueling process more convenient for operators. Additionally, it is compatible with Cummins fuel tanks, ensuring a proper fit and function within the system.

Installation and Usage

Proper installation of the Cummins 3864276 Filler Cap is crucial for its effective operation. It should be securely fastened to the fuel tank to ensure a proper seal. Users should follow the manufacturer’s instructions for installation to avoid any issues. When in use, the cap should be opened carefully to prevent any sudden release of pressure that could cause fuel to spill.

Maintenance and Care

To ensure the longevity and optimal performance of the Cummins 3864276 Filler Cap, regular maintenance is recommended. This includes periodic cleaning to remove any buildup of dirt or fuel residue. Inspections should be conducted to check for any signs of wear or damage that could compromise the cap’s sealing ability. If any issues are detected, the cap should be replaced to maintain the integrity of the fuel system.

Troubleshooting Common Issues

Users may encounter issues with the Cummins 3864276 Filler Cap, such as leaks or difficulty in opening. If a leak is detected, the cap should be inspected for damage and replaced if necessary. Difficulty in opening the cap may indicate a build-up of pressure within the tank, and care should be taken to release this pressure slowly to avoid spills.

Safety Considerations

When handling and maintaining the Cummins 3864276 Filler Cap, it is important to adhere to safety protocols. This includes proper handling of fuel to prevent spills and inhalation of fumes. Operators should wear appropriate personal protective equipment and ensure that the area is well-ventilated during maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation, providing reliable products that meet the demanding requirements of commercial transportation.

Cummins Engine Filler Cap Compatibility

The Cummins part number 3864276, a Filler Cap, is designed to fit a variety of Cummins engines. This filler cap is a component for maintaining the proper operation and integrity of the engine’s fuel system. Here is a detailed breakdown of the engines with which this filler cap is compatible:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of the earlier generation of Cummins engines. The filler cap 3864276 is specifically designed to fit these models, ensuring a secure seal that prevents fuel contamination and loss of fuel pressure.

QSB Series Engines

The QSB series engines, including:

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The filler cap 3864276 is compatible with these QSB engines. These engines are known for their reliability and performance in various applications, from agricultural to industrial use. The filler cap ensures that the fuel system remains sealed and protected from external contaminants.

QSC and QSL Series Engines

The QSC and QSL series engines, including:

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL9 CM2350 L102

The filler cap 3864276 is also designed to fit these engines. These engines are typically used in heavy-duty applications, and the filler cap plays a role in maintaining the integrity of the fuel system under demanding conditions.

Role of Part 3864276 Filler Cap in Engine Systems

The part 3864276 filler cap is a component in the arrangement of various engine systems, ensuring the seamless operation and maintenance of these systems.

Oil Fill System

In the oil fill system, the filler cap plays a role by providing a secure and sealed point for adding oil to the engine. This is essential for maintaining the proper oil level, which is necessary for lubricating moving parts, reducing friction, and preventing wear and tear. The cap ensures that contaminants are kept out of the oil, preserving its quality and effectiveness.

Cover and Cylinder Block

The filler cap is often mounted on a cover that is attached to the cylinder block. This cover houses the oil filler tube and other components related to the oil system. The cap’s sealing properties are vital in preventing oil leaks from the cover, which could lead to a loss of lubrication and potential engine damage.

Oil Filler Tube

The oil filler tube is directly connected to the filler cap, serving as the conduit through which oil is introduced into the engine. The cap ensures that the tube remains sealed when not in use, maintaining the integrity of the oil system. This sealing function is important for preventing oil spills and ensuring that the oil level within the engine remains consistent.

Conclusion

The Cummins 3864276 Filler Cap is a versatile and essential component for commercial trucks, ensuring the efficient and safe operation of the fuel system. Its compatibility with a wide range of Cummins engines, from the 4B3.9 and 6B5.9 to the QSB, QSC, and QSL series, underscores its importance in maintaining the integrity of the fuel system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.