3629112

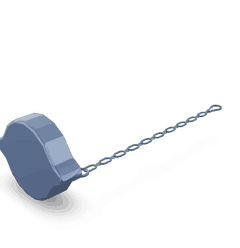

Filler Cap

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3629112 Filler Cap is a component designed for use in the fueling systems of commercial trucks. Its primary role is to facilitate the secure and efficient transfer of fuel into the vehicle’s tank while preventing spillage and ensuring the integrity of the fuel system.

Purpose of the 3629112 Filler Cap

The 3629112 Filler Cap serves a vital function in the fueling process of a truck. It is responsible for sealing the fuel tank, thereby preventing fuel from leaking out and ensuring that contaminants do not enter the tank. This cap also plays a role in maintaining the pressure within the fuel tank, which is important for the proper operation of the vehicle’s fuel system 1.

Key Features

The Cummins 3629112 Filler Cap is constructed from durable materials that are resistant to the corrosive effects of fuel. It incorporates a sealing mechanism that ensures a tight fit on the fuel tank, minimizing the risk of leaks. The design of the cap includes features that make it easy to open and close, while also providing a clear indication when it is properly secured 2.

Benefits

Using the Cummins 3629112 Filler Cap offers several advantages. It enhances fuel security by providing a reliable seal that prevents fuel loss. The cap’s design allows for convenient and safe refueling, reducing the likelihood of spills. Additionally, its robust construction ensures long-term reliability, contributing to the overall efficiency and safety of the truck’s fueling system 3.

Installation Process

To install the Cummins 3629112 Filler Cap, first ensure that the fuel tank opening is clean and free of debris. Align the cap with the tank opening and turn it clockwise until it reaches the designated stop, indicating a secure fit. It is important to follow the manufacturer’s instructions to ensure proper installation and function 4.

Troubleshooting Common Issues

Common issues with the 3629112 Filler Cap may include leaks or difficulty in opening. If a leak is detected, inspect the cap for signs of damage or wear and ensure it is properly seated on the tank. If the cap is difficult to open, check for any obstructions or debris around the tank opening that may be preventing a proper seal 5.

Maintenance Tips

Regular maintenance of the Cummins 3629112 Filler Cap is important to ensure its continued effectiveness. This includes cleaning the cap and tank opening to remove any buildup, inspecting the cap for signs of wear or damage, and replacing it if necessary to maintain the integrity of the fuel system 6.

Safety Considerations

When handling and maintaining the Cummins 3629112 Filler Cap, it is important to observe safety practices related to fuel handling. This includes working in a well-ventilated area, avoiding smoking or open flames near the fuel tank, and wearing appropriate personal protective equipment to prevent contact with fuel 7.

Environmental Impact

The proper use and maintenance of the Cummins 3629112 Filler Cap contribute to reducing environmental risks associated with fuel spills. By ensuring a secure seal on the fuel tank, the cap helps prevent leaks that could lead to soil and water contamination. Additionally, its role in maintaining the pressure within the fuel tank can help reduce emissions 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial vehicle, industrial, power generation, and marine markets, providing reliable and efficient solutions for a wide range of applications 9.

Compatibility of Cummins 3629112 Filler Cap with Various Engines

The Cummins 3629112 Filler Cap is designed to fit a variety of Cummins engines, ensuring a secure seal that prevents fuel contamination and loss of pressure within the fuel system. Below is a detailed description of the compatibility of this filler cap with various Cummins engines.

Compatible Engines

- GTA38 G CMEICS G116C, K38, K50, KTA38GC CM558

- QSK38 CM2150 MCRS, QSK38 CM850 MCRS, QSK45 CM500

- QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G

- QSK78 CM500, QSK95 CM2350 K111, QSK95 CM2350 K113

- QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G

Role of Part 3629112 Filler Cap in Engine Systems

The Part 3629112 Filler Cap is an essential component in the maintenance and operation of various engine systems. It is specifically designed to integrate with several key components to ensure the efficient functioning of the engine.

Integration with Oil Fill and Breather Systems

The Filler Cap is primarily used in conjunction with the oil fill and breather systems. It seals the oil fill port, preventing contaminants from entering the crankcase while allowing for easy oil addition. The breather system, which includes the crankcase breather and dipstick/fill hand hole, relies on the Filler Cap to maintain a clean and controlled environment within the crankcase. This is vital for the proper ventilation of gases and vapors produced during engine operation 10.

Connection to Dipstick and Hand Hole Components

The Filler Cap also plays a role in the dipstick system. By sealing the dipstick fill & breather arrangement, it ensures accurate oil level readings are taken via the oil level gauge. Additionally, it complements the hand hole cover and dipstick/fill hand hole, providing a secure point of access for maintenance tasks such as oil changes and inspections 11.

Interaction with Lubricating Oil Systems

In lubricating oil systems, the Filler Cap works in tandem with the lubricating oil filter and full flow oil filter. It ensures that the oil introduced into the system is clean and free from debris, which is essential for the filters to operate effectively. This, in turn, helps maintain the integrity of the engine’s lubricating oil, promoting longer engine life and optimal performance 12.

Coordination with Crankcase Components

The Filler Cap is also integral to the crankcase system. It interfaces with the crankcase explosion valve and the breather/dipstick/fill hole arrangement. This coordination helps in managing the pressure within the crankcase, preventing any potential damage from excessive pressure build-up 13.

Overall System Harmony

By fitting seamlessly with these components, the Part 3629112 Filler Cap contributes to the overall harmony and efficiency of the engine system. Its role in sealing, protecting, and facilitating access to various engine components underscores its importance in maintaining engine health and performance 14.

Conclusion

The Cummins 3629112 Filler Cap is a critical component in the fueling and engine systems of commercial trucks. Its design and functionality ensure the secure transfer of fuel, maintain the integrity of the fuel system, and contribute to the overall efficiency and safety of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

SAE International. Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩ -

Cummins Inc. Troubleshooting and Repair Manual. Bulletin Number 3666184-00.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.